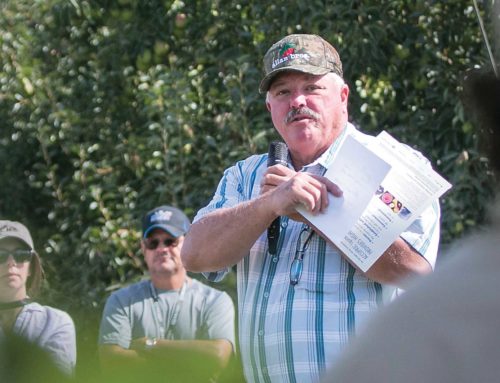

John Verbrugge explains his tree training system for Honeycrisp. The trees are on a modified-V system.

(Geraldine Warner/Good Fruit Grower)

John Verbrugge has used bench grafts and full-grown nursery trees in his orchards and comes down in favor of the nursery trees. Finished nursery trees cost twice as much as bench grafts, but after analyzing the numbers, Verbrugge, whose family operates Valley Fruit based in Yakima, Washington, thinks the extra cost is a good investment. The trees come into production a year earlier and the break-even point is a year earlier.

“The sooner you pay off the block, the better off you are,”

he commented. Though some growers prefer to use bench grafts or sleeping eyes because of the lower up-front investment, Verbrugge thinks that when all the costs are added up, including the cost of perhaps 15 to 30 percent tree loss, there’s not that much to be gained. “They’re just gaining the big headache of doing all the work the nursery does,” he added. In a 38-acre block of Honeycrisp planted in 2003, he used finished trees on six acres and bench grafts on the rest.

Verbrugge said he couldn’t get full-grown trees in time for the planting and some of the bench grafts were ordered before he’d had the chance to analyze results from previous plantings. From the six acres of nursery trees, he harvested 56 three-quarter-full bins of fruit (equivalent to about 40 full bins) in the second leaf. He didn’t fill the bins in order to avoid bruising. Peak sizes were 48 and 56. He had no crop on the bench grafts.

Tree training

The trees are spaced 3.5 feet apart in the row, with 14 feet between rows. He uses Gala trees as pollinizers, as they bloom at about the same time as Honeycrisp. He uses a modified V training system with four wires spaced 18 inches apart, and the top wire at 9 feet. The cost of materials and labor to install the trellis was between $1,500 and $1,800 per acre. He’s using wooden end posts instead of steel because of the rising price of steel. Strong, upright growth in the center of the tree is removed to maintain good light penetration, and remaining upright limbs are pulled down and attached to the wires with plastic tubing.

Weak growth is tipped to encourage branching to fill in the space. Weak trees are pruned aggressively. Between 50 and 75 percent of the fruit can be picked from the ground with this system. Verbrugge said when the trees are young, workers are transported down the rows on trailers to do pruning and thinning, but as the trees mature, the work goes slower and the trailer becomes too cumbersome. He thinks the system would be appropriate for mechanical harvesting, but he doesn’t think the mechanical harvesting aids currently available offer much of an advantage over using ladders. Honeycrisp matures soon after Gala, and he has his pickers harvest it right after the first Gala pick.

The orchard is on a steep, north-facing slope. He thinks that is appropriate for Honeycrisp, which doesn’t do well in intense heat. Honeycrisp is prone to bruising and the fruit is run across the packing line at a slow speed, like Golden Delicious. Verbrugge said most of the ranch is planted with Red Delicious on M.106 rootstocks, trained to a Y-trellis system. “There’s definitely some thoughts of grafting over.” But he’s concerned about having more Honeycrisp because of the logistics at harvest time.

He’s heard that the variety needs several picks and the stems might need to be clipped. Also, picking three-quarter bins, rather than full ones, in order to avoid bruising, adds to the labor requirements at a time when Gala also needs to be picked and Golden Delicious will mature soon afterwards. “You’ve got to be realistic,” he said. “I would like to see about a 10 percent mix of everything—except Honeycrisp until we learn more about it. I think we’re going to be surprised at the amount of problems we run into on them.”

Leave A Comment