A patternator on the right measures the spray output and location from the tower sprayer. (Courtesy of Washington State University)

The goal of any orchard or vineyard sprayer should be to hit the canopy target. But many sprayers fail to hit their mark and often apply anywhere from less than half to one and a half times the material needed, according to a Washington State University survey.

“Your goal should be that your entire spray stays within the canopy row,” said Gwen Hoheisel, WSU extension specialist. “You want every drop that comes from your sprayer to end up in the canopy.”

Hoheisel says there are simple things that can be done to improve hitting and covering the target and the quality of the spray material.

Research has shown that only about half the spray from an average orchard or vineyard sprayer reaches target. Of the half that misses, most hits the ground and the rest goes airborne as spray drift.

“Half of a $60 per acre spray on the ground is a lot of wasted money,” she said during winter tree fruit and grape talks in Washington.

When WSU checked spray patterns and nozzles of 20 orchard sprayers throughout Washington’s tree fruit industry with a patternator, a device that shows where spray has gone, none of

the sprayers were working as the growers intended and only one had 100 percent of the nozzles working properly.

“One grower had 60 percent of the spray going to the lower 48 inches of the tree,” said Hoheisel. “That’s not an effective spray.” Another sprayer was leaving gaps at around seven to eight feet high.

Improve hitting target

To better hit the target, growers first need to know where their spray is going. Vertical patternators are commercially available, but they are designed for research and are expensive. However, growers can build one for around $500 in materials, following instructions available on the Internet, according to Hoheisel.

Food-grade dye or clay material like kaolin can be easily used to visually show air direction and deposition. Even stapling a paper to a board affixed in the row and using dye in the sprayer can give an idea of where sprays are hitting.

If there are gaps in the spray pattern, air direction can be changed by using a wrench to adjust nozzle positions, she added. “You have a very powerful tool when holding a wrench.”

“The problem is in matching airflow from older sprayers designed for larger canopies to these modern orchard systems,” she said. Even with new sprayers, there is a mismatch early in the season and in spraying young trees because canopies are not fully developed.

But Hoheisel says there are easy ways to reduce airflow when necessary. One way is to adjust the gearbox to reduce fan speed. Another is to use plywood donuts, technology developed by Cornell University to reduce airflow.

Improving coverage

In the near future, some sprayers will allow the applicator to adjust spray louvers from the tractor cab, opening and closing them as desired. Even more precise will be sprayers currently being developed in the United States and Europe that use laser technology to detect location and density of the plant and foliage, and adjust spray outputs automatically. Such technology promises to dramatically reduce the use of spray materials while reducing spray drift.

Nozzles (droplet size), pressure, and speed are factors involved with improving how the sprayer covers the target.

“You want a lot of small drops that stick to the leaf surface,” she said, recommending that growers aim for 60 to 90 drops per square centimeter, which equates to about 395 to 580 drops per square inch. Generally, droplet size greater than 300 microns will bounce off the canopy, while smaller than 150 microns will drift off the target.

High air pressure results in fine droplets, low pressure in coarse, large drops.

“So many of us never change the pressure gauge on the sprayer,” she said, noting that manufacturers generally guarantee pressure gauges for a year and it’s easy to spot nonworking pressure gauges because the needle either bounces or doesn’t return to zero when at rest. “But gauges have a tendency to slow down and not be as accurate even though they appear to be working.”

Pressure that’s too high results in too much air volume and can lead to pesticide runoff. Volumes too low can result in poor coverage. She recommends that pressure gauges be tested annually (a testing kit is available for $100) or replaced before each spray season.

Nozzles come in many shapes, resulting in various droplet sizes and spray patterns. Though some nozzles are more resistant to plugging, all can get clogged at some point. A regular maintenance program to clean sprayer nozzles and filters is key in making sure sprays go where they’re wanted.

Replacing nozzle tips can make a big economic difference. Generally, 20 percent of the nozzles on a sprayer are worn and need replacement, Hoheisel reported. “If you buy 16 new ceramic nozzle tips for your sprayer at $5 each, that’s a cost of $80 total. Those nozzles will pay for themselves in about five acres if you were off by 20 percent.”

Improve spray quality

Sprayer speed is the last component that affects coverage. The optimum ground speed when driving a sprayer is 2.5 to 3.5 miles per hour.

Sprayer speed is the last component that affects coverage. The optimum ground speed when driving a sprayer is 2.5 to 3.5 miles per hour.

“Realistically, many orchard spray applications are done at 5 mph,” Hoheisel said. “I understand growers have a lot of acreage to cover, but studies have shown that you don’t save that much time increasing speeds from 3.5 to 5 mph. But you greatly affect the coverage and efficacy of your spray.”

Affordable devices are available to track accurate ground speed (which is not the same as tractor speed) and with GPS, where the tractor has been. “Then you know how fast the operator was going and exactly what rows were covered,” she said, noting that commercially sold rate control systems also calibrate the amount of spray that’s been programmed for the sprayer.

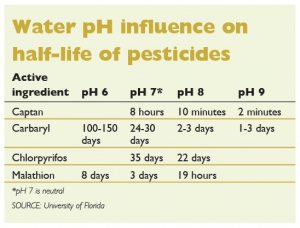

Don’t overlook water pH used in mixing pesticides, she noted. Water with a pH of 8 or higher can greatly reduce the efficacy of a pesticide, shortening its half-life. Conversely, a pH of 6 can lengthen the half-life and cause pesticide residue issues. The half-life is how long it takes for half of the pesticide to degrade.

An inexpensive pH meter, available for around $50, can measure water pH and provide accuracy within 0.2 pH points.

Hoheisel urges growers to calibrate their sprayers at least annually. A host of YouTube videos give calibration demonstrations. Flow rate meters can also be used to test nozzle output.

“We monitor so much of our pest control programs, but we don’t monitor enough of what we’re doing with our sprayers,” she said. “With inexpensive tools now available to help us test, calibrate, track, and monitor our sprayers, we can make big changes. Simple, low-cost adjustments and changes, like replacing nozzle tips, can bring immediate improvements.” •

To make your own patternator, visit: patternator.com.

——-

There are lots of calibration videos on YouTube and Hoheisel recommends the three listed below.

Easy Way to Sprayer Calibration, Penn State University: youtube.com/watch?v=0shwWW1d4zY

Backpack and Handgun Calibration, Wyoming Weed and Pest Council: youtube.com/watch?v=NKlarXKD-Y0

Calibration of Airblast Sprayers for Vineyards, Part 2, Andrew Landers: youtube.com/watch?v=_mAB41soyxE

Leave A Comment