Ines Hanrahan during the Honeycrisp session at the Washington State Horticultural Association’s annual meeting in Kennewick, Washington on December 3, 2014. (TJ Mullinax/Good Fruit Grower)

Assessing fruit quality of Honeycrisp at harvest helps packers decide which lots to put in long-term storage. But Honeycrisp does not fit parameters of most other apple varieties, so which quality attributes should be measured, and how?

Titratable acidity, chlorophyll, and dry matter were discussed as potential quality measurements for the fickle apple variety during a half-day session on Honeycrisp, organized by Washington State University and the Washington Tree Fruit Research Commission. The session was in conjunction with the Washington State Horticultural Association’s annual meeting, held in December in Kennewick.

Harvesting Honeycrisp at the right maturity can mean the difference between packing and shipping the fruit immediately or storing it for later, with potential for higher returns. Honeycrisp picked too early can develop bitter pit in storage, but overmature fruit tends to develop soggy breakdown and internal browning.

Maturity indicators for Honeycrisp include red color, with background color breaking from green to yellow and starch conversion of around 4.5 to 5.0 on the six-point scale, says Dr. Jim Mattheis, physiologist for the U.S. Department of Agriculture in Wenatchee, Washington. But fruit acidity is also important for Honeycrisp quality.

Titratable acidity

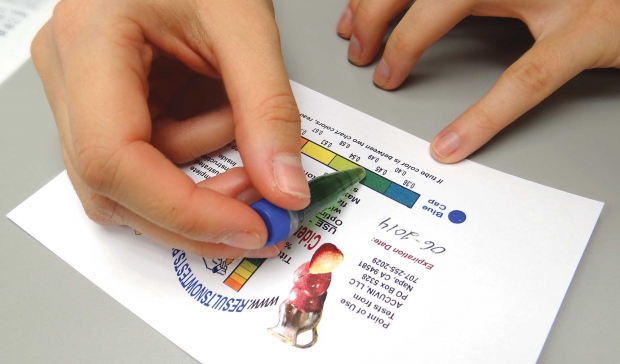

Colorimetric test kits that measure titratable acidity are easy to use. Those designed for hard cider measure malic acid and need no conversion as do ones made for the wine industry. (Courtesy Washington Tree Fruit Research Commission)

“Fruit acidity (malic acid) is what apples live on once off the tree. It’s the gas or fuel for fruit in storage,” Mattheis said. He recommends using malic acid as a predictor for long-term storability in Honeycrisp apples.

In apples, malic acid is the predominant acid, making up 90 percent of all acids in the fruit. It contributes to taste, but doesn’t last forever; levels go down during storage.

“That’s why when you get into May and the summer months of storage fruit, the acidity often gets low and fruit lose their fresh flavor,” said Mattheis.

Titratable acidity (TA) of apples varies by cultivar, season, and within orchards. Mattheis has found a big range of acidity among apple varieties. For example, at harvest, the range of acidity for Red Delicious is 0.2 to 0.3 percent, compared to Granny Smith of 0.7 to 1.0 percent. Honeycrisp varies from 0.3 to 0.7 percent.

Additionally, TA levels change during the harvest window as apples mature. In the same orchard, acidity levels started at 0.5 percent on September 6 but had dropped to 0.34 percent by October 11.

His research shows that TA levels also can vary from orchard to orchard, with differences significant enough that consumers could taste the difference.

“Because acidity is a predictor of long-term storability, there is value in knowing the acid levels at the start,” said Mattheis. “All apples lose acid during storage, but the ones with the highest values at the start have the highest values at the end.”

Controlled atmosphere (CA) technology slows fruit respiration and helps preserve acidity. Packing house operators can moderate acidity values with SmartFresh (1-methylcyclopropene), but levels will still drop during storage, he noted.

Acidity can be measured relatively easily and accurately with colorimetric test kits. The wine industry routinely uses titratable acidity kits to measure tartaric acid. If using a kit that measures titratable acidity based on tartaric acid, calibration to convert it to malic acid will be needed.

Ines Hanrahan of the Research Commission has used a kit designed for hard cider makers that measures titratable acidity reported as malic acid, so no conversion factor is necessary. Samples cost less than $2, including labor to run them, and results are available in about 30 seconds.

She found the results of her particular kit to read about 10 percent higher than a titration sample run on expensive laboratory equipment. “Though each measurement is a mere estimation, it is consistent and will enable warehouses to group lots by acidity levels,” said Hanrahan.

For packing houses running around 100 samples, Mattheis believes the test kits could provide an estimate of acidity levels and should be considered, especially if they are currently not testing. Larger warehouses may want to invest in more sophisticated equipment.

As a general guide, he said the higher the acidity level (as long as fruit has good color), the longer the fruit should keep its flavor in storage. Data shows that .5 percent and higher will retain acid levels longer and respond better to long-term storage than lower numbers. He found freshness differences in apples with .4 and .46 percent acidity in trials.

DA meter

The Washington Tree Fruit Research Commission found that a foam cushion is needed to act as a visor for the DA meter when taking readings in the sun. (TJ Mullinax/Good Fruit Grower)

Hanrahan is working with a new tool called a DA meter that holds promise in tracking maturity in the orchard. It was initially developed by a researcher in Italy to assess peach maturity. The hand-held device retails for around $4,000 and measures chlorophyll in the mesocarp of the fruit.

From Hanrahan’s preliminary experiments with the device in 2013, she learned:

—DA meter needs to be shaded from the sun when taking readings from apples on the tree (she devised a visor to shade the lens from the sun).

—Two readings per apple, averaged together, gave a representative sample.

—Taking readings at a consistent time of day gave best results.

Her initial experiments with the DA meter in a Honeycrisp orchard showed close correlation with other maturity indicators, such as soluble solids concentration and starch conversion index. But when she expanded the trial in 2014 to several Honeycrisp orchards, she couldn’t find the same correlations.

“The DA meter did track maturity in the orchard over time and could be used to separate lots for storage,” Hanrahan said, adding that the DA meter tended to correlate with background color rather than percentage of red color.

“The lack of correlations isn’t surprising, when you consider that we’re working with Honeycrisp, a variety that doesn’t conform to behavior of other varieties and seems to do things for no rhyme or reason,” she said.

Nonetheless, Hanrahan is intrigued with the DA meter’s nondestructive nature and ease of use, and she is continuing evaluations to learn if there is utility in predicting cold sensitivity and storability of Honeycrisp at harvest.

Dry matter

Dry matter concentration of apples is receiving worldwide attention as another way to measure quality and predict storage potential. New Zealand’s John Palmer, Stuart Tustin, Roger Harker, and others recently published the study “Fruit Dry Matter Concentration: A New Quality Metric for Apples.”

Chris Willett of ENZA Fruit Products has been using dry matter for several seasons to assess fruit quality of ENZA varieties.

Dry matter is the solid substance of an apple when all water is removed and mainly consists of soluble carbohydrates, vitamins, and minerals.

Dry matter content can be determined easily by dehydrating apple slices, a process that requires a dehydrator and is minimal in cost, but it takes 24 to 48 hours. Because of the slow and destructive nature of using a dehydrator, apple researchers are exploring near-infrared technology (NIR) to measure dry matter concentration and other fruit quality attributes from tree through storage.

“High dry matter concentration is the goal in apples,” said Willett. In his work with ENZA apples, he’s found that the correlation between dry matter concentration and soluble solids increases during storage periods.

High-density training systems that get more light interception into the canopy help increase dry matter in fruit, but there is variability between varieties and within orchards due to canopy structure, horticultural practices, and cultivar-specific characteristics.

“It’s not an absolute value of dry matter that we should focus on but the value within a variety,” he said. For example, Scifresh (Jazz) has an average dry matter concentration of 15.4 percent compared to 15.9 percent for Sciros (Pacific Rose) and 16.7 percent for Scilate (Envy). He has not sampled Honeycrisp. The goal is to produce fruit in the upper range for that particular variety, which for some of the varieties he’s tested is around 15 percent.

As NIR technology is adapted to the fruit industry, he believes growers and packers in the future will use hand-held devices and sorting technology to assess dry matter and other quality attributes in the orchard and through the packing process as a way to predict and assess quality and storage potential. He also sees potential to match high-flavor fruit with high-end markets. “However, proper harvest timing will still be critical.” •

Leave A Comment