Pruners stand on the upper level of the platform, which is about four feet off the ground. Growers who hopped on board during a field demonstration found it a smooth ride. (Photo by Bill Reinert

A mechanized pruning platform garnered generally favorable reviews from about 50 camera-wielding farmers who gathered for a field demonstration this spring at Allan Brothers orchard in Grandview, Washington. In use for several weeks on apple blocks, the experimental model has reduced labor costs by about 25 percent by eliminating the use of ladders, said Dr. Dana Faubion, a Yakima-based Washington State University Extension educator, who arranged the demonstration.

Faubion is developing the self-propelled platform as part of a team of four agricultural scientists. Other team members are WSU tree fruit educator Karen Lewis, who is studying the social and ergonomic impact of the platform on workers; Tom Auvil, an Orondo grower and a research horticulturist with the Washington Tree Fruit Research Commission; and Clark Seavert, agricultural economist with Oregon State University and superintendent of the Mid-Columbia Agricultural Research and Extension Center in Hood River. Faubion has been tinkering with a platform developed by Dr. Donald Peterson with the U.S. Department of Agriculture in West Virginia. The machine, which he emphasized is only a crude prototype, is aimed at eliminating ladders, a major source of worker injuries and fatigue.

Europe

In use in Europe for the past 20 years, the platforms are designed for use in trellised blocks. A contingent of Northwest growers and agricultural experts traveled to Europe three years ago to observe growing methods there. Faubion returned nursing a long-term plan to introduce the machine to growers here. Mounted on a two-level frame, Faubion’s prototype resembles a huge go-kart, with one big wheel in front and two in the back.

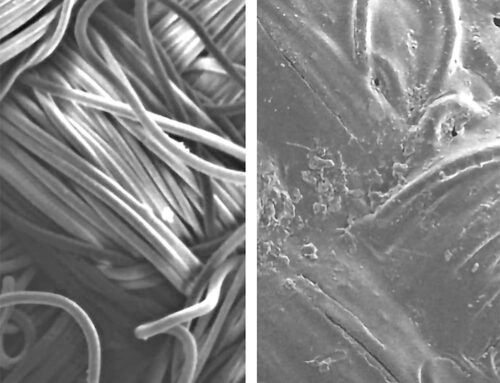

Pruners stand on the upper level, which is about four feet off the ground and about five feet wide, and prune the trees’ upper branches as the platform creeps along. During the trial stage, pruners are working without the restraint of a railing or harness. Spectators who hopped on board the prototype during the demonstration found it a safe, smooth ride. The steering mechanism is set to pull slightly to the right; a telescoping sensor protruding from the right front of the platform corrects the steering when it encounters a trunk or other obstacle.

“The slight meandering is a good thing,” Auvil said. “It allows (the platform) to work through obstacles because it’s not set to go in a straight line.” Faubion has been monitoring workers and conducting efficiency studies. “It’s always hard (evaluating) prototypes, but we’re saving 25 percent, and it feels really safe when you’re up there standing on the platform,” he reported. Auvil said the productivity increase is predictable. “When you’re just on the platform, you can focus on the cutting; there’s no interruption in your train of thought,” he said.

Two-dimensional canopy

The first block on which the platform was demonstrated was an 8.2-foot by 3-foot trellised Gala block in which the tree limbs were trained along the wires so that the canopy was two-dimensional. A two-man crew, with no restraining devices, cut away steadily and speedily with hand shears as the platform crept along for a very smooth ride. A second block of 13- to 14-foot tall Galas on a 13.5- by 7-foot spacing with a three-dimensional canopy was problematic.

Because of the wider rows, workers had to lean over to get at branches, which was neither safe nor comfortable, as they had no restraining device and were subject to back strain or injury. The third and final trial was in a 13.5- by 5-foot Golden Delicious block, with trees trained on a V-shaped trellis. Because the canopies were angled, forming an arch, they were far more accessible to the pruning crew. Faubion said the angled canopies are a little more efficient for ladder use, as workers can cut the trees on both sides from a ladder set in the middle of the path.

The trellised blocks’ dimensions were ideal for the modified platform, said Faubion, who believes the time is right for the technology. “That’s the system they see going into the future, looking out about five years. The future looks good.” Bob Murphy, foreman at a 600-acre apple orchard in Royal City, Washington, owned by McDougall & Sons, Inc., liked what he saw at the demonstration.

“It’s got some promise,” Murphy said while watching the trial. “We could use it right now, if they made a few adjustments, like installing pneumatic pruners. Faubion said that while his platform in theory can accommodate pneumatic equipment, he is trying to keep his trials as basic as possible. Pneumatic machinery will probably be tested on two new platforms he plans to purchase with grant money from the Washington Tree Fruit Research Commission, he said.

Leave A Comment