Farming is one of the four most dangerous of U.S. occupations, resulting in more on-the-job deaths and injuries than all other types of work, except for logging, fishing, and mining. Three people died in orchard tractor and machinery accidents last summer in Washington State, prompting state labor officials to remind growers of the importance of accident prevention.

Ten people died, primarily from tractor rollovers, all-terrain-vehicle (ATV) accidents, and overhead wire electrocution, in labor-intensive crops between 2007 and 2012, according to the Washington State Department of Labor and Industries. The crops were tree fruits, berries, nuts, grapes, nursery plants, and ornamental plants. Seven tractor-related fatalities occurred in 2010; three in 2012.

Of the three orchard fatalities last summer, one involved an orchard owner who became pinned between a cherry tree branch and his tractor; the second was an orchard worker changing a tractor tire on a sprayer attached to an idling tractor who was run over; and the third was an orchard worker who was crushed from a three-wheel forklift that went over a steep edge of an orchard road.

Workplace claims and violations

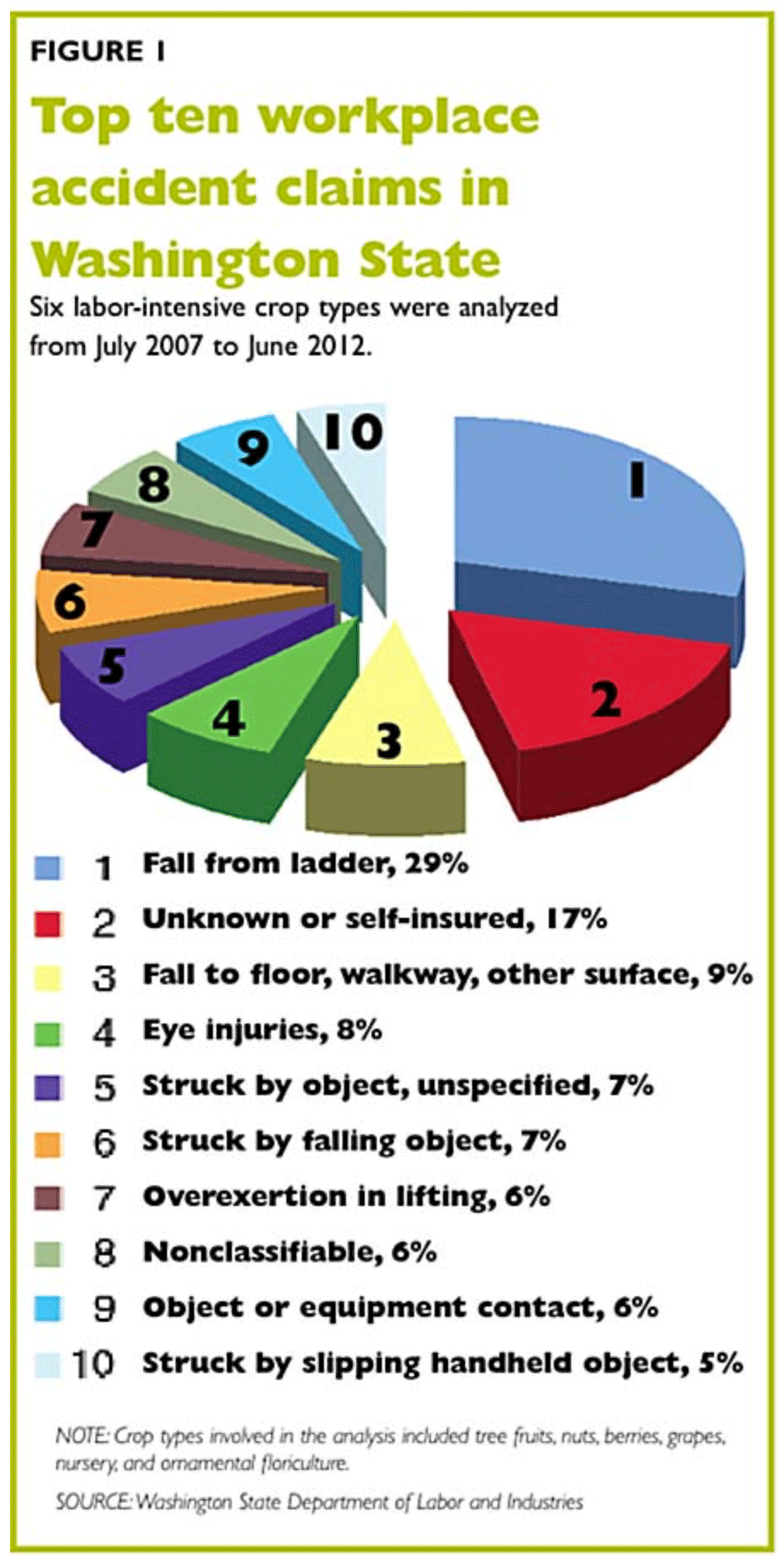

During the 2007–2012 time frame, ladder falls were the most reported workplace claim in labor-intensive agriculture, said Pedro Serrano, Hispanic outreach and technical services coordinator for L & I, in an interview with Good Fruit Grower (see Figure 1).

Reasons given for ladder falls included moving while climbing or descending, an unstable base, missteps, overreaching, and damaged ladders. Training workers how to safely use ladders and to thoroughly inspect and repair them before use can help avoid ladder accidents, Serrano said.

Figure 2 shows the type of worker safety violations that state officials found during their inspections. The highest number (25) was for testing and performance of tractor rollover protective structures (ROPS). Protective structures are required for all tractors, with the exception of low-profile tractors used in orchards, vineyards, or hop yards where the vertical clearance requirements would substantially interfere with normal operations, and for work related to these uses. A few other exceptions are provided in the state code. Seatbelts must be provided and worn where ROPS is required.

Tractors that meet the state’s definition of a low-profile tractor are only exempt from needing ROPS if the structure interferes with overhead clearance during work performed. During a winter talk given to grape growers, Serrano said that ROPS are designed to provide a protective zone for the driver and, when coupled with a seatbelt, can keep the operator safe in the event of a rollover.

“Of the seven tractor fatalities in 2010, five involved tractors overturning,” he said, adding that two of the three fatalities in 2012 had ROPS but they weren’t in place.

“I’ve never seen a fatality occurring from a tractor rollover that had a functioning ROPS,” Serrano said. “It takes 45 seconds to put the ROPS in the upward position. They work, but you have to use them, and the seatbelts.”

Accident prevention program

Safety standards in Washington State require employers to have an accident prevention program. Accident prevention involves workers and management in workplace safety and should be a living plan that is continually modified and improved.

Core elements of a prevention program, outlined in Chapter 296-307 of the Washington Administrative Code, Part B, are:

—A written plan tailored to needs and hazards of your operation (the plan must deal with how, when, and where to report accidents and illnesses, location of first-aid facilities, emergency plans, identification of hazardous chemicals, use and care of personal protective equipment, and on-the-job review, and more)

—Employee instruction in safe working practices at beginning of employment

—Monthly walk-around safety inspections with employee representative

—Monthly foreman and crew safety meetings

Communication

Serrano emphasized that workers must be trained how to use hazardous chemicals safely before they are exposed.

“The biggest factor in accidents is that they weren’t trained in a language they understand,” he said, adding that workers also need to be effectively supervised while working.

“It takes five to six years to reach proficiency in a second language and five to ten years for someone learning a new culture to reach second-culture proficiency,” Serrano said.

The challenge for employers, he said, is in bridging that five- to ten-year language and culture gap before an accident happens.

Leave A Comment