Mike Omeg does not know who started the jokes about his massive new trellises, but he has heard them. One has it that the poles can be seen from space. Another dubbed his 25 acres of trellised cherry blocks “Omeginsanity.”

Mike Omeg spent two years planning this 25-acre trellis system. He doesn’t expect to recoup his costs for at least five more years. (TJ Mullinax/Good Fruit Grower)

He embraces the term now. “I don’t know which neighbor said that, but I don’t even care,” he said. “I think it’s fun.”

He has 26 more acres planned by 2020.

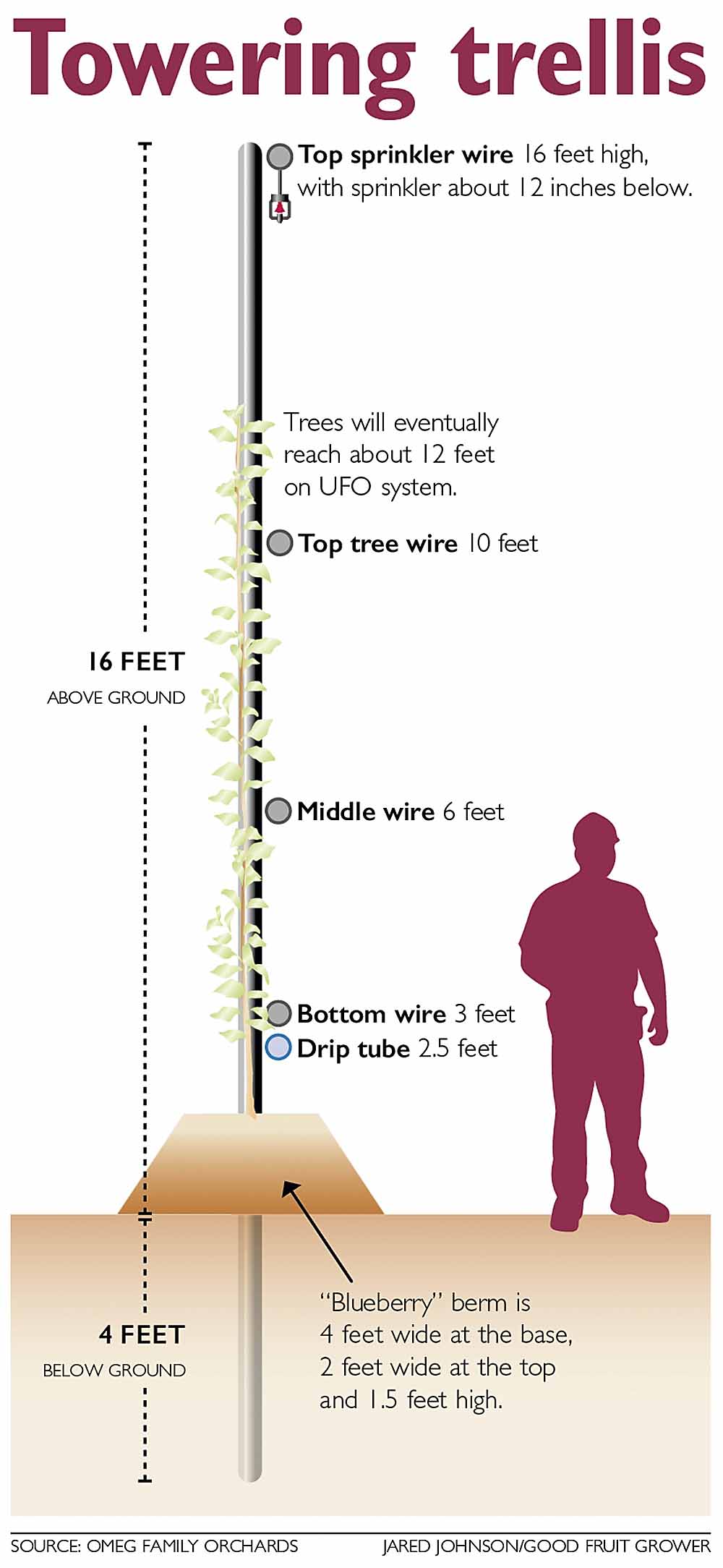

Take a look at a few of the specs:

—Twenty-foot poles made of U.S. steel — 16 feet above ground, 4 feet below — that are tall enough to accommodate 12-foot trees and still leave room for netting.

—Microsprinklers up top, drip irrigation on bottom.

—Coated trellis wire.

—Eleven-foot rows with 6-foot spacing between trees for upright fruit offshoot training.

He planted Krymsk 6 rootstocks in the spring, and in September grafted on sleeping eye Royal Helen shoots.

Omeg doesn’t mind the jokes but disagrees that his project is crazy. He has spent two years planning the trellis, studying results from large Washington fruit companies that use trellises.

Most of those are V-trellises, while Omeg is planting UFOs, he said, making comparisons difficult. However, he decided to make his structures even sturdier.

He uses thicker, Pennsylvania steel and anchors 4 feet below ground in dense, loamy soils, compared with the sandy soils elsewhere.

Grower of the Year Mike Omeg’s latest trellis system uses 20-foot poles made with U.S. steel and coated horse fencing wires, with microsprinklers on top and drip irrigation at the base. The “blueberry” berm helps to concentrate the soil and nutrients. Source: Omeg Family Orchards. (Jared Johnson/Good Fruit Grower illustration)

He also makes interior rows just as beefy as the exterior rows because the steep slopes expose all of them to the high winds that have made the nearby Columbia River a favorite destination for windsurfers.

He can’t speak for every Washington trellis, but many use thinner imported steel, anchor in sandy soil and reinforce only the exterior few rows, he said.

“Is it beefier than the average? Oh, heck yeah,’” he said.

Paying for it was, and still is, a challenge. For decades, he and other growers typically replaced older trees a little at a time, paying for the effort from annual revenue.

Mike Omeg, Omeg Family Orchards

He has spent about $8,300 per acre just on the cost of materials and installing the trellises, not including the price of the trees or the loss of a few years in production. His financial model calls for recouping his costs in year five or six.

“I was a little bit shocked,” admitted his father, Mel. “I wanted him to be able to explain why.” So he did. Mike convinced his father with carefully crafted predictions of increased fruit size, quality and profitability, Mel said.

His mother, Linda, who long managed the financial side of the family farm, also agreed.

Mike Omeg is the general manager of the farm, Omeg Family Orchards, but his parents, who now live in Lincoln City, Oregon, near the Pacific Coast, still own the land and participate in some of the bigger farming decisions.

Mel also agreed that growers in Washington and Oregon have used trellises successfully and believes it will work for his son. “These systems of trellises are not as new as you would think,” Mel said. “It’s just our community has been way, way behind.”

Many growers in Washington installed tall trellises more than a decade ago. Omeg has visited them, studied them and heard the lessons learned from growers. Some plant 150 acres of trellis cherries at a time. “It’s not a rash decision,” he said.

Even a few growers in Omeg’s neighborhood have tried their hands at trellises.

Orchardview Farms, one of the largest fruit companies in The Dalles, has about 25 acres of trellised orchards in commercial production, after working with Washington State University’s researchers to test them. They are about 8 or 9 feet tall.

Looking at Omeg’s, “I don’t see how you can pay for that,” said Bob Bailey, minority owner and former CEO of Orchardview.

Bailey is a longtime neighbor, has known Omeg since he was a child, and lauds his farming practices.

“Mike has good ideas,” Bailey said. “Not everyone agrees, but he is as successful as he can be.”

Omeg doesn’t expect everyone to agree.

He believes all growers in the Columbia Gorge should at least test out trellises but doesn’t prescribe his choices for everybody. “This is what I’m doing for me,” he said. •

– by Ross Courtney / illustration by Jared Johnson / photos by TJ Mullinax

Leave A Comment