Gaurav Dhumal, Washington State University researcher, adds a solution of water and gum arabic (Acacia senegal) to a Skeena cherry processing line in Washington last July, during the third year of a research trial to reduce cracking in fresh market cherries. The solution is an edible coating the cherries are drenched in, after which they are immediately dried by a custom air-blast fan (hoses on the left of the photo) before being packed for shipment. (TJ Mullinax/Good Fruit Grower)

You can’t see it or taste it or feel it, but researchers believe it could make a big difference in preventing cherry cracking.

After four years of experiments with various coatings designed to protect the fruit from absorbing excess moisture that pools in microscopic pores on the fruit’s surface, Washington State University researchers are now fine-tuning the use of a fine film of gum acacia.

Also known as gum arabic, it’s a commonly used and low-cost food additive that’s harvested as it exudes from a gum acacia tree.

“So far, again and again what we are seeing is that the gum acacia is showing the most promise,” said Girish Ganjyal, a food technology researcher at WSU. “At the same time, we have to make sure we remove all the excess moisture with the air knives or any other technique.”

Washington State University researcher Girish Ganjyal holds a beaker containing a solution of water and gum Acacia senegal in his laboratory in Pullman, Washington, in October. A. senegal, a commercially available edible coating, is showing the most promise in trials to reduce cherry cracking. (TJ Mullinax/Good Fruit Grower)

Ganjyal plans one more season of testing the technique in packing houses to find the optimum approach. After trials with more than a dozen coating variations, he’s down to comparing gum from two different but closely related acacia trees at 0.5 percent concentration with water.

It reduces or at least delays fruit splitting. Adding modifiers such as agar and sodium to the gum acacia solution didn’t improve performance.

“It’s not going to eliminate all the cracks, but it will delay the cracking, and that’s really what we are looking for to sell the cherries for an additional week,” he said.

For the trials, the researchers have focused on cherries most at risk of cracking, such as those picked in the July heat or after a rain, Ganjyal said.

The gum acacia coatings have the added benefit of reducing stem browning in addition to lowering the likelihood of cracking. So far, it’s been tested on Skeena, Chelan and Sweetheart cherries, all with similar effects.

At the packing house, the coating is poured over the cherries, which then pass under blasts of air that knock off excess water quickly. In lab experiments, giving the cherries a quick dip into the coating solution works just as well.

Following the coating with blower air knives ensures only a very thin, almost imperceptible, layer remains on the fruit.

This year, the researchers encountered a problem during their trial at one Washington packing house.

A new mesh drain belt under the air knives didn’t allow the water to drain fast enough, so too much water and excess coating remained on the fruit, causing some samples to mold after four weeks in storage.

Water droplets pool up on Skeena cherries after they’ve been coated with gum Acacia senegal and dried by a custom air-blast fan during research trials in July 2017. (TJ Mullinax/Good Fruit Grower)

That did not happen during the 2016 season, when the drain belt that was used had large pores so that it could drain more efficiently.

Lesson learned; now the researchers know to advise packers who want to try out the coatings to make sure they are using a rapidly draining belt for this process, Ganjyal said. “The bigger the pores, the better.”

People who tasted the coated cherries and conventional fruit after three weeks in storage as part of a sensory analysis last summer couldn’t detect any difference in taste or texture and preferred them equally. Ganjyal said they are planning an additional sensory test next summer, hopefully after five weeks in storage.

“The gum acacia doesn’t have any unique taste. You can’t tell,” he said. “When you touch and feel the solution, it’s not sticky, it’s just like water.”

Since such a low concentration of gum acacia — just 0.5 percent — is needed to create an effective coating, it should be a relatively low-cost option for packers.

They are also testing the gum acacia coating in combination with desiccant packing liners to offer additional moisture control.

So far, the data seems to show liners with 2 percent desiccant are more reliably effective, compared to 4 percent or 6 percent, so next year’s focus will be on the lower levels of desiccants, Ganjyal said.

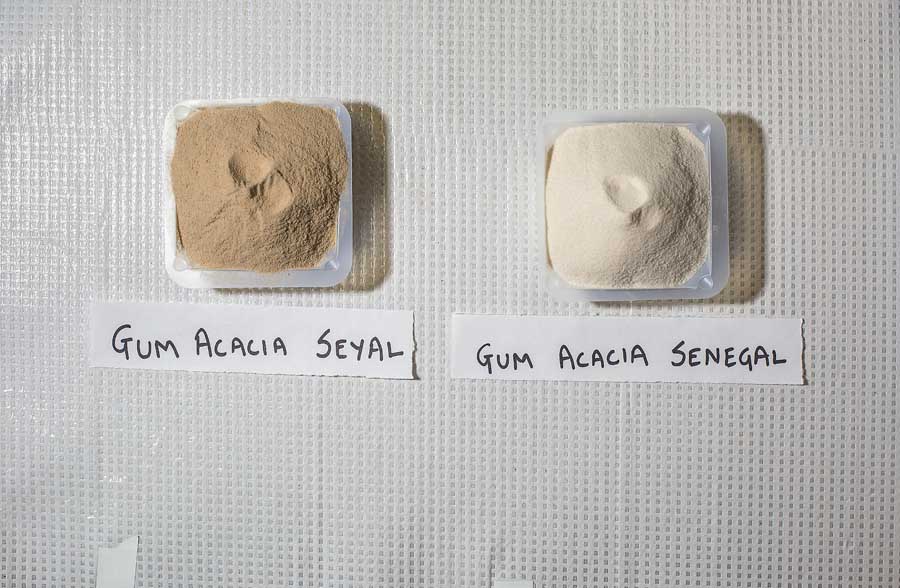

Examples of two commercially available edible gum coatings being tested by Girish Ganjyal and his WSU research team in the hopes of finding a method to protect cherries, and possibly other pome fruits, from postharvest issues. Ganjyal’s team has found Acacia seyal to work very well in trials, however Acacia senegal has shown the most promise. (TJ Mullinax/Good Fruit Grower)

The coming season is the last year of the trial funded by Washington and Oregon cherry growers through the Washington Tree Fruit Research Commission, but Ganjyal and other cherry researchers are also seeking Specialty Crop Research Initiative (SCRI) funding to continue the exploration of postharvest practices to prevent cracking and browning.

Though he plans further refinement to the technique, Ganjyal is optimistic that it works well enough for packers to try it out for themselves.

“If anyone would like to try it out in their facility next (season), we’d be more than happy to help,” he said. •

by Kate Prengaman

Leave A Comment