Dr. Louise Nelson, center, and students Daylin Mantyka, left, and Danielle Hirkala check apples at the University of British Columbia.

By Terry Edwards

Researchers in British Columbia, Canada, have developed a DNA-based method of detect- ing and preventing rot in apples during cold storage. Dr. Louise Nelson, a soil microbiologist at the University of British Columbia- Okanagan, and Dr. Peter Sholberg, a plant pathologist at the Pacific Agri-Food Research Centre in Summerland, are using DNA macroarray technology to detect fungal pathogens that cause rotting.

Spores land on apples while they’re on the tree, but they don’t develop until the fruit is in storage, Nelson said. Once one apple is infected, the rot can spread to other apples and infect whole bins.

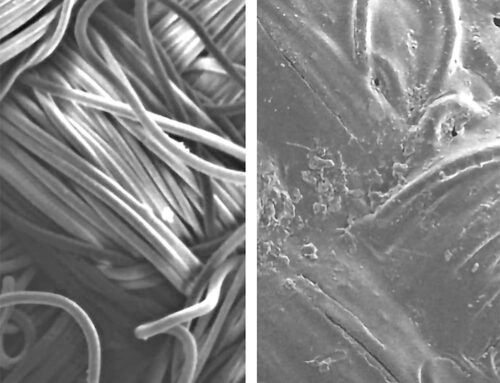

The pathogens that commonly cause postharvest decay in apples are: Penicil- lium, which causes blue mold; Botrytis, which causes gray mold; and Mucor, which causes mucor rot. Detecting these pathogens before the apples go into stor- age would allow producers to limit postharvest rot by keeping the affected apples out.

“Most of the early work on the detection element was done by Peter Sholberg’s labo- ratory,” Nelson said. “In 2006, Peter started looking at the macroarray for diseases of apples, and now we’re focusing on the main pathogens that occur after harvest because the losses are significant: depending on the year, anywhere from 5 to 10 percent to as much as 20 percent.

“If we can detect when the apples are coming in, whether they are heavily contami- nated by spores or not, then the decision can be made not to put the apples into storage, and redirect them for sale or processing.” Early detection is only one of the researchers’ goals. They are also examining alternative methods of controlling the rots using soil bacteria that suppress the growth of all three pathogens.

Nelson studied the ability of soil bacteria to repress fungal pathogens on plants while at the University of Saskatchewan and brought with her to the Okanagan a collection of bacteria that she had isolated from soil samples. Since the samples came from cold soil, they are ideal for use in controlled atmosphere cold storage. “You need something that would grow at low temperatures and inhibit the fungus that causes decay,” she said. “What we found is a number of these environmentally friendly organisms they don’t cause disease in humans are very effective in suppress- ing the pathogens. We’ve been getting really good control of the disease. It just doesn’t develop over a period of months.”

Although the practical application of the bacteria treatment is still a number of years away, the detection component could be implemented as early as this fall. Nelson said they are working with the Okanagan Tree Fruit Cooperative, which has set up a new lab in Winfield, near Kelowna. One of her colleagues, Danielle Hirkala, is working with the cooperative two days a week starting this fall to see if growers can either bring in a sample or the packing house depot can take a sample from a batch of apples coming in from an orchard and get the result within 24 hours.

Right now, there is no process in place to detect pathogens with the accuracy and speed required, she said. There is a provincial lab in Abbotsford, where samples could be sent to be cultured, but it can take days or even weeks to get the results back, so the apples would have already gone into storage, and the disease might have already spread.

Outlay

The DNA detection process involves taking a small amount of DNA from an apple or air sample, amplifying it in a thermal cycler, then applying it to probes that are attached to a membrane. To equip a lab for DNA testing, the most expensive item is the thermal cycler, which costs less than $10,000, Nelson said.

“It’s not a huge outlay. We figured out that the cost to equip a lab to do this kind of work would be $18,300 total, then the cost per sample would be about $10, and then you need to pay a technician to do the work.” The scientists have been sampling air, leaves, blossoms, and fruit at four apple orchards throughout the season, looking at when the pathogens occur and when they are most common during the growth cycle of the apple.

That way, they can build a prediction model so growers can determine if they are likely to have disease when the apples go into storage, whether they need to apply a fungicide or a biological control for the disease, or whether they want to sell those apples off quickly because there is going to be a problem, Nelson said.

The bacterial isolates could be used instead of a fungicide, which might be useful for organic production, she said. Only two fungicides are registered for use in Canada for postharvest disease in apple, and one has been in use for such a long time that the pathogens have become resistant to it. Another challenge is how to apply the bacterium.

“The apples are floated in a dump tank, and the dump tank usually has a little bit of bleach or sodium hypochlorite in it to help kill the pathogens, but what often happens is you’re infecting all the apples as they go along,” Nelson said. “Before the apples go back into the bins, they are sprayed with a coating of wax because the sorting procedure removes the natural wax on the apples. When you’re spraying the apple with wax, it might be very easy to apply the bacteria at that time.” However, there is also a possible adverse public perception to overcome.

“We’re not sure whether people would want bacteria sprayed on apples,” she said. “I think we’re getting more used to the idea that there are beneficial bacteria around. There is more and more interest in moving away from chemical-based fungicides and pesti- cides and moving towards more environmentally friendly products, and this would be an example of something like this. After the apples have been in storage for four or five months, we expect there are very few bacteria left anyways.”

Nelson said this is their second year of research, and the process will likely require a couple more years of testing, then it would have to be registered with the federal government to be sure it’s safe. “We’re probably looking at a five-year time frame,” she said.She pointed out that other fruits and vegetables could also benefit from the procedure.

“Pears are affected by similar diseases as apples, but we also think it would be very useful for other types of fruit; even greenhouse tomatoes and peppers are subject to Botrytis, so it could be very useful for berries and grapes, anything that is harvested and kept cool for a period of time before it’s consumed.” The research is sponsored by the Advanced Foods and Materials Network, a federally funded network of scientists.

Leave A Comment