As commercial apple growers plant more profitable high-density orchards, those longstanding traditional orchards, with wide rows of stately trees 20 feet tall, are gradually becoming a thing of the past.

The sprayers growers use to apply chemicals in these newer orchards? Not so much yet. Instead, at the start of each season, many growers roll out the airblast sprayers their grandfathers used, along with the widely held belief, “If it ain’t broke, why fix it?”

Those sprayers, designed or built in the 1960s, feature a large axial fan to push a liquid spray of water and chemicals across wide rows and into huge canopies.

Growers needed those sprayers in traditional orchards, but today, orchard systems have changed, and in modern orchards they are often spraying at too high a volume, too high a speed and missing their targets.

That’s the message of Andrew Landers, a faculty fellow at Cornell University’s Atkinson Center for a Sustainable Future and one of the world’s leading spray technology researchers.

Landers touted the benefits of modern sprayers at the International Fruit Tree Association Study Tour in New York in July, saying growers can more effectively deliver their spray, thereby reducing chemical use, drift and cost, than they can with those so-called “legacy sprayers.”

Of course, Landers also recognized that many growers may not be in a position to buy a machine worth hundreds of thousands of dollars — there’s a reason some people still use granddad’s sprayer. For those growers, he recommended tips and tools for improving effectiveness.

The dynamics of spray

These two images show how a property of fluid dynamics, known as the boundary layer effect, can impact spraying an apple. At higher air speeds, as shown in the left photo, most spray droplets go straight past the apple. But lower air speeds, which have a lower boundary layer, allow spray droplets to go around and land on the back of the fruit. (Courtesy Andrew Landers)

It’s all about matching air speed and volume to the growth stage of a vineyard or orchard canopy. Too little air results in poor penetration, while too much results in spray drift and a failure to adequately deposit the spray where it’s needed.

The latter point seems counterintuitive, but in 1904, a little-known German physicist named Ludwig Prandtl revolutionized fluid dynamics with his theory that high air speed applied in a liquid diverges around an object when it reaches it and then converges again behind it.

The untouched area on the backside of the object and behind it is referred to as the boundary layer. The greater the air speed and the rounder an object — like, say, an apple — the larger the boundary layer.

In addition, the large canopy of a traditional orchard allows for more turbulence to be created; when the air flow hits the tree, that turbulence in the canopy causes droplets to fall out of the spray cloud and stick to fruit and leaves.

“Now, with these modern trees and narrow, very narrow, very well managed canopies — we have trees that are summer pruned, exposed apples — we no longer have that air turbulence,” Landers said.

The spray launches onward, rather than stick to the tree. Which means growers need to start thinking differently about how they apply their chemicals, he said, particularly since sprayers only provide between 55 and 65 percent coverage anyway, resulting in “huge wastage.”

Understanding canopy density

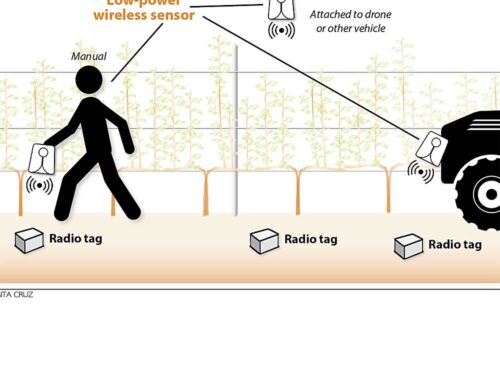

Cornell researchers show how attaching a series of ultrasound sensors to a sprayer provides information about gaps in the tree canopy and, by controlling the fan, reduces air speed. (Shannon Dininny/Good Fruit Grower)

Landers already has patented a louver technology, a metal panel that can be retrofitted to a traditional airblast sprayer, to adjust air flow. Now he and his postdoctoral researcher, Tomas Palleja, are studying ways to estimate canopy density to reduce air flow where it’s not needed.

The density of a fruit wall can vary anywhere from 30 to 75 percent, but too often, growers fail to adjust the air flow for the canopy. They also can’t see what’s making it through to the other side of the canopy.

The researchers attached a series of ultrasound sensors to the sprayer to gather information about the canopy volume and density; a sparse tree requires far less spray. The sensors act as both microphone and receiver, sending a very high frequency sound wave.

When the sound hits the leaves, it bounces back to the receiver. If there’s a gap in the branches or leaves, it passes through, providing details about the gaps in the canopy.

These sensors also control the speed of the fan. Previous studies with a single-row sprayer have shown adequate coverage when the air leaves the fan at 7 mph, Landers said. Airblast sprayers typically shoot spray at speeds of up to 190 miles per hour.

Overall, adjusting the air flow to keep the spray in the canopy allows for the volume of water to be reduced from 100 gallons to just 65 gallons per acre.

“That’s quite an appreciable amount of water,” Landers said. “We would still try to maintain the label rate. We’re not proponents of skimping on the amount of product, primarily because it’s risk and reward — if you take the risk in reducing the amount of product, your reward might be quite low.”

Applying the sensors to a single-row sprayer at Lamont Fruit Farm in Albion, New York, enabled the farm to reduce sprays to every other row, requiring 50 percent less fuel, according to co-owner Rod Farrow.

“All our fire blight, everything we spray for is every other row. We run at 5 mph and use 50 percent less fuel,” he said. “We have to run PTO (power take-off) a little faster, we’re down a gear, but we’re still close to 5 mph.” A two-row sprayer Farrow has on the farm runs at close to 5.3 mph.

The research team also successfully applied the sensors to a traditional airblast sprayer equipped with the louver system.

Cornell University researchers showed off a multi-row sprayer July 19, 2016, at the International Fruit Tree Association Study Tour in Waterport, New York. (Shannon Dininny/Good Fruit Grower)

The researchers have developed an in-canopy flow system still to be commercialized.

Called the Electro-leaf, the small, triangular sensor simulates a leaf in the canopy, vibrating when the air flow hits it and sending a signal to adjust fan speed.

To have more flexibility to adjust spray volume, Landers also recommended using nozzles in clusters. Connecting the sprayer to a bank of four color-coded nozzles, each applying spray at a different rate enables a grower to combine the nozzles in different combinations for up to seven different rates.

For instance, banks of nozzles can be used when there are variations in canopies, such as small replant trees next to large, mature trees, or where there are blocks of different varieties requiring different application rates.

The nozzles are commonly used on boom sprayers in the Midwest, he said.

Growers need to adjust the tools used today to meet their modern needs, not only to attract workers — “Why disrespect the $10-per-hour worker and give him granddad’s sprayer to use?” Landers asked — but also to attract young people to agriculture. Technologies that employ the latest software applications and high-tech features to automate the industry, such as robotic harvesters and precision sprayers, are one way to do so.

“We want to bring the industry forward, and we want to bring young people into the ag industry,” he said. “And I submit to you that legacy sprayers are not the way to do it.” •

Guides for growers

Andrew Landers, Ph.D., has released a new book, “Effective Orchard Spraying: A Practical Guide for Growers,” that offers tips for sprayers owners and operators to get the best from their machine and spraying operation.

Andrew Landers, Ph.D., has released a new book, “Effective Orchard Spraying: A Practical Guide for Growers,” that offers tips for sprayers owners and operators to get the best from their machine and spraying operation.

In addition, a second edition of his 2010 spray guide for wine and juice grape growers, “Effective Vineyard Spraying: A Practical Guide for Growers,” is also available. For more information or to order either book, visit www.effectivespraying.com.

– by Shannon Dininny

Leave A Comment