Last season, Washington harvested 13 million boxes of organic apples and even more are expected this year, which means that packing houses will need to step up their storage capabilities to accommodate more organic fruit for a longer season.

Traditionally, most organic apples have a shorter season, since it’s challenging to protect the quality of some varieties for long-term storage without fungicides and 1-MCP (1-methylcyclopropene), the ethylene inhibitor in SmartFresh.

“1-MCP is the closest thing to a silver bullet we have. Without it, things are more difficult,” said Glade Brosi, who works for Storage Control Systems, a Michigan-based company that sells storage equipment.

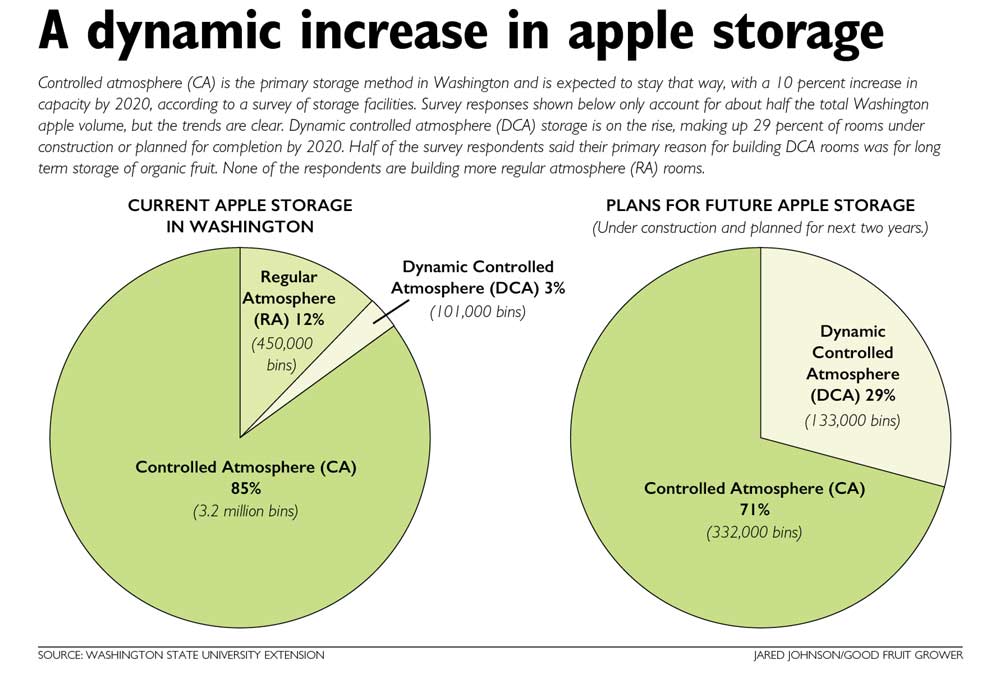

A dynamic increase in apple storage: Controlled atmosphere (CA) is the primary storage method in Washington and is expected to stay that way, with a 10 percent increase in capacity by 2020, according to a survey of storage facilities. Survey responses shown below only account for about half the total Washington apple volume, but the trends are clear. Dynamic controlled atmosphere (DCA) storage is on the rise, making up 29 percent of rooms under construction or planned for completion by 2020. Half of the survey respondents said their primary reason for building DCA rooms was for long term storage of organic fruit. None of the respondents are building more regular atmosphere (RA) rooms. (Source: Washington State University Extension. Graphic by Jared Johnson/Good Fruit Grower)

Many organic packers just shoot for a November to March marketing window when they can offer the best fruit quality. Now that production has doubled, that season is going to get crowded, and postharvest practices to extend quality become more valuable, he said.

“For just one room of organic fruit, you can get $150,000 more for that same fruit if you can get that fruit from March to May,” Brosi said.

To do that, some packers are turning to dynamic control atmosphere storage, DCA, which monitors fruit respiration so that lower oxygen levels can be used than in traditional CA. Storage Control Systems sells a tool for tracking fruit stress during DCA to set optimum atmosphere levels, known as a SafePod, that’s caught the eye of organic packers. Alternative technologies include HarvestWatch, which tracks chlorophyll fluorescence in the peel of the fruit as a sign of stress, and systems that monitor ethylene production, such as Storex.

These technologies will help warehouses figure out how best to fine-tune their practices for organic fruit, said Jim Mattheis, a postharvest physiologist and research leader for the U.S. Department of Agriculture’s tree fruit program in Wentachee, Washington. But more research is needed to figure out how to best take advantage of these instruments and integrate them into existing systems, he said.

This winter, Storage Control Systems is working with packers around the world storing $100 million worth of fruit with SafePods, Brosi said. But making the change isn’t easy.

“With 1-MCP, you can store at 3 percent oxygen. We’re asking people to store at 0.7 percent oxygen and 0.5 percent carbon dioxide. The energy demand is higher and the quality of the room has to be higher,” he said.

Almost all of Washington’s apples are currently stored in CA – 85 percent of the storage volume according to a recent survey by the Washington State Tree Fruit Association. Just under 3 percent is currently DCA, but of the new capacity being built, 40 percent is DCA, said Rob Blakey, former Washington State University Extension postharvest specialist, who conducted the survey. And DCA capacity had already doubled in just the past few years.

DCA and lower oxygen levels than conventional CA are great tools to delay a wide variety of postharvest senescence disorders, Mattheis said. However, when those tools are used alone, apples can begin to metabolize again and lose firmness and flavor when the fruit is removed from storage for packing, shipping and retail sale.

“One of the great things about 1-MCP is that it continues to provide an effect once the fruit has left storage, when it’s sitting on the shelf in retail,” he said. Letting fruit sit for a long time in air storage poses more of a risk with organic fruit, which presents a logistical problem for supply chain management. But there is also a need for more research to find the optimum temperatures for air storage to minimize these issues for different cultivars, Mattheis said.

Washington researchers have done little postharvest work focused solely on organic apples, but that is starting to change, said Ines Hanrahan, project manager of the Washington Tree Fruit Research Commission. The WA-38 (Cosmic Crisp) storage trial this winter includes an organic scenario; early data suggests the fruit retains high quality for 12 months on its own.

WSU’s postharvest fruit school in March will include sessions on organic postharvest issues, featuring a presentation by Severine Gabioud, a Swiss scientist who specializes in organic postharvest practices, such as the use of ozone.

Broadly, there is still a lot to learn about better organic postharvest practices, Hanrahan said, because “quite frankly, some of our standard varieties don’t store well organically.”

Honeycrisp, for all its challenges, actually performs well without 1-MCP because it retains its signature crispness and flavor, Brosi said, especially the new red strains that allow for better control of harvest maturity.

Galas, on the other hand, the state’s largest organic product, are prone to get soft and mealy during storage without 1-MCP. Fujis can lose acidity quickly once removed from CA, and Granny Smiths are difficult to store organically because they are prone to superficial scald unless treated with DPA.

That’s why ongoing research by USDA scientists into biomarkers that can warn warehouse managers if fruit is likely to develop scald presents particular promise for organic fruit, Mattheis said. Biomarkers also show promise for predicting for chilling disorders in Honeycrisp.

“One of the nice things about using biomarkers is that it is applicable for conventional fruit as much as organic. But say you’ve got organic Granny Smith you’d like to be able to hold until June or July, but you are not sure if it’s going to scald. That could keep you up at night,” Mattheis said. “Providing a test helps you make that decision with more information.”

Another challenge: There are no organic postharvest fungicides. One alternative is to use ozone, which prevents spores from moving and infecting pristine fruit. Organic growers also prioritize orchard sanitation because they know they have fewer tools in the toolbox to control disorders after harvest.

But the increasing volume of organic apples should enable warehouses to fill and close rooms faster and start CA or DCA sooner. Waiting a week or more while the room fills before initiating the low oxygen level makes it less effective, Mattheis said.

“We’ll see what happens in the next five years,” Mattheis said. “This is actually a really good time for this to be happening with the technology that’s available to see what fruit are doing and look at them in the predictive way.” •

by Kate Prengaman

Leave A Comment