Dr. Larry Schrader

Washington State University

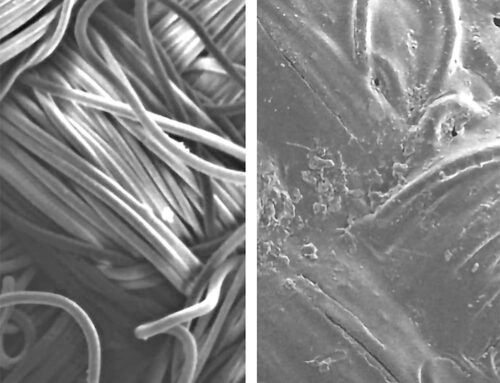

Dr. Larry Schrader knew he was onto something. The Washington State University horticulturist had been studying sunburn of apples and developed a waxy film that could be sprayed on the trees to protect the fruit from heat stress damage. One of the immediately obvious benefits was that the product did not leave a visible residue like the kaolin material that some growers were using, and it also could be used in conjunction with evaporative cooling, since it didn’t wash off.

By 1998, the research was finished, and the product was at the point that that growers could use it, but Schrader spent more than six anxious years trying to commercialize it and obtain a patent. The university owns any invention made by WSU faculty, and the WSU Research Foundation is the entity that manages the intellectual property. The faculty member files an invention disclosure, and the foundation decides whether or not it will apply for a patent. If the decision is to go ahead, the university contracts with patent attorneys in Seattle who work with the inventor to write the patent.

The Research Foundation pays the considerable expenses involved in preparing and filing the patent. Generally, the patent application works its way through the U.S. Patent Office and is either approved or disallowed. In the meantime, the Research Foundation looks for potential licensees for the product. In the case of Raynox, the university first filed for an international patent and learned that it would have to be separated into three patent applications, which would triple the cost. Filing fees would have cost almost $500,000, and Schrader did not know how well the product would be accepted at the time.

“I about dropped the phone,” he recalled. He and the foundation decided there was no way the university could pay those kinds of fees, so they decided to apply just for a U.S. patent. It takes money to make money, Schrader noted, and the university did not have the resources. In 2001, scientific articles about his invention were published, which meant that potential competitors had access to information about his research. Anxiously, he waited for the U.S. patent office to approve the patent. The Research Foundation checked and kept reporting that it would be approved any day.

Another two years went by, and Schrader’s anxiety was increasing. Then, the U.S. Patent Office said it couldn’t find the application. “I was about to tear my hair out,” said Schrader. The patent attorneys resubmitted the application three times. Finally, they asked someone at the Patent Office to stand by the fax machine while they faxed it to them. The application then went to the back of the queue.

Working on it

Working on it At grower meetings in 2002, Schrader had indicated that the product would be available soon. “The phone started ringing and people said, ‘Where can we get it?’” Schrader recalled. “I said, ‘We’re working on it.’” He’d tried to find a company to produce it, but none would take the risk of licensing the product without a patent to protect them from someone making a competing product.

“I didn’t know what I was going to do because I had gone through about every formulator I could contact and I got the same answer,” he said. “I finally decided that the only way this was going to happen was if I forked out my own money and took the risk on this thing.” He approached the WSU Research Foundation, which told him he could not start his own company to launch the product because it would be a conflict of interest.

The dean of the College of Agriculture said the same thing. Then, Schrader read an article in a newsletter by the WSU Provost Dr. Robert Bates, who said the university should do a better job of commercializing the intellectual property of its faculty. Schrader wrote to Bates explaining the situation, and asked for permission to start a company so that the Raynox technology could be licensed and supplied to the growers. Bates approved it.

Schrader launched a company called FruitGard LLC with a partner. Both put money into the venture so they could license the technology from the university. They reimbursed the foundation for the costs of obtaining the patent, and they pay license fees and a royalty. Pace International then agreed to manufacture and distribute Raynox under contract to FruitGard, but Pace does not sell directly to growers. When Schrader talked to distributors about supplying the product, he got the cold shoulder. They told him he’d have to give them a lot of product so they could test it themselves.

“They have snake oil salesmen come in the door every day, and they put me in that class,” Schrader said. “Was that a downer!” But Schrader had credibility with growers who had heard him talk about Raynox at meetings, and they started asking their orchard supply companies for it. In 2003, the material was available on a limited basis. By 2004, it was distributed on a wider scale, and Schrader estimates that about 35,000 acres were treated.

But it was not until February 2005 that the Patent Office approved the patent. Schrader said launching the product before the patent had even been examined was risky, and he was alarmed when the examiner first of all refused the application. “I wasn’t feeling very good that night,” he said. But after input from Schrader, the examiner eventually approved it.

Rain cracking

Rain cracking Meanwhile, he has developed a different film designed to prevent rain cracking in cherries. Schrader said it’s a totally different material from Raynox. He started out trying Raynox on cherries, but it affected the fruit finish.

“I had to have something that made the cherries look better, not worse,” he said. Schrader plans to commercialize it the same way as Raynox, through FruitGard LLC. It was in field trials with ten growers last season and looked promising, particularly in Oregon, where there was substantial rain. “The growers want it,” he said. “They’ve already broken one of my arms, and they’re twisting the other one, but I’m thinking we may do another year of testing. I want to be sure. I want it to be a winner like Raynox. I have a lot of confidence in it, but I’m thinking we may let selected growers test it this next year.”

Leave A Comment