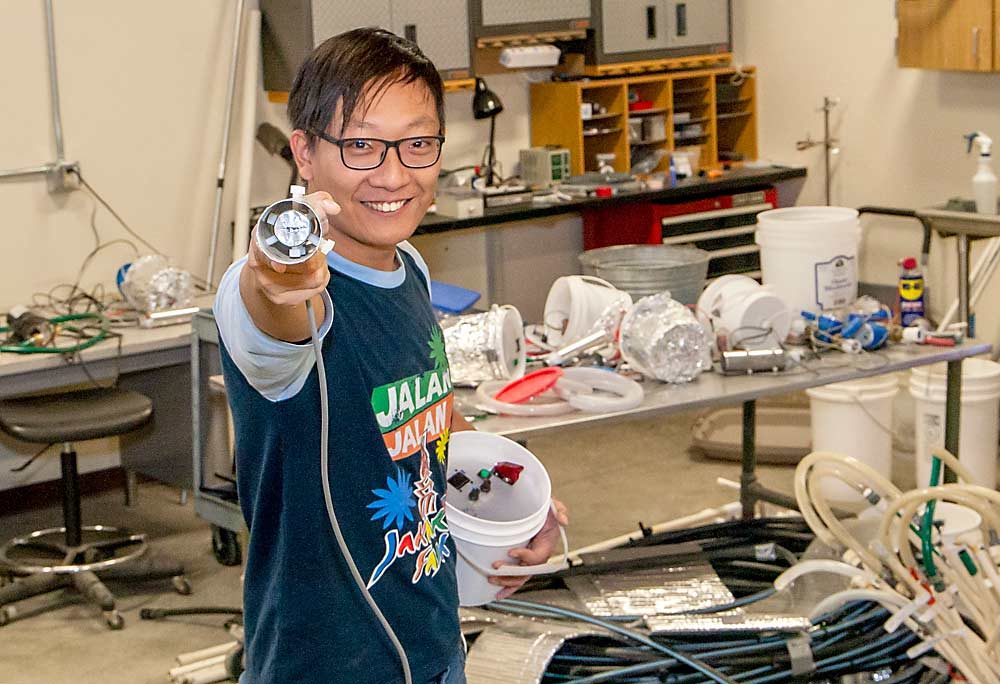

Ben-Min Chang housed his infrared thermometer in a wine can with the bottom cut out. His circuit box and control center? He encased it in a plastic paint bucket.

Despite the makeshift materials, the Washington State University researcher has shown his concept for an automatic evaporative cooling system for wine grapes works.

When grapevines get too hot, they shut down and grapes won’t ripen. Chang’s goal is to mist and cool down the grape-growing environment without wetting the grape clusters themselves or the ground.

“We need to wet leaves but not the soil,” he said in November at the Washington State Grape Society’s annual meeting in Grandview, Washington. That way, cooling doesn’t interfere with deficit irrigation, promote disease or waste water.

In trials in Cabernet Sauvignon blocks at WSU’s research vineyard at the Irrigated Agriculture Research and Extension Center in Prosser, Chang’s do-it-yourself cooling system brought down canopy temperature by an average of 8 degrees Fahrenheit without affecting vine shoot length, node number, lateral shoot and leaf counts, berry weight, Brix and titratable acid, compared to an unmisted control block. Only pH showed significant change; it dropped a little with mist, compared to control.

Meanwhile, most of the water he sprayed attached to the surface of leaves, not clusters. Moisture on grape clusters during ripening can promote powdery mildew, a fungal pathogen.

“Don’t be afraid, my approach is not hydrocooling,” he said, referring to the use of overhead sprinklers to cool down plants.

Apple orchardists often use evaporative cooling to prevent sunburn, but they turn their systems on manually once temperatures reach the risk threshold. Chang wants to automate the process.

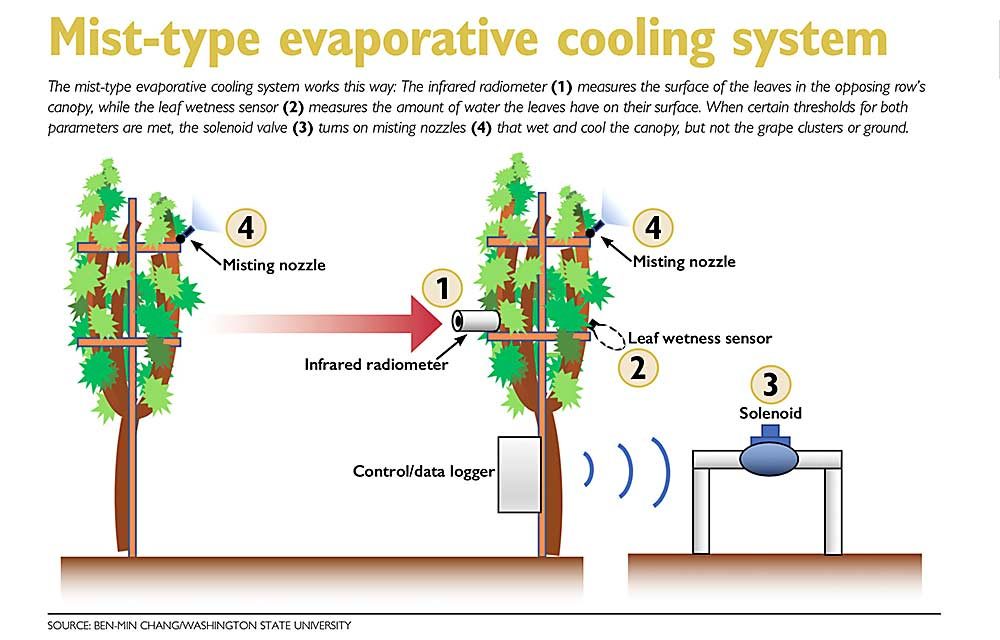

Here’s how his prototype works: An infrared radiometer, mounted in one row, points at the neighboring row and measures the surface temperature of its leaves, more precisely than a thermometer measuring ambient air temperature in the canopy. Meanwhile, a leaf wetness sensor measures the amount of water on the leaf surface. When certain thresholds for both parameters are met, a solenoid turns on misting nozzles, designed to wet and cool the canopy but not the grape clusters or ground. It turns itself off when either of those parameters reverts.

So far, he has stored temperature, humidity and leaf wetness data on data recorders inside each bucket. He has to walk the rows to collect them, but in the future, he envisions a system that will transmit instructions to a solenoid valve to turn the misters on and off.

For the trials, he set the turn-on threshold at 95 degrees, a generally accepted point at which vines shut down photosynthesis and clusters cease ripening.

His project, which ran in 2018 and 2019, was an offshoot of a heat-stress project led by Yun Zhang, another WSU-Prosser researcher, funded at $245,428 for three years by a Washington Specialty Crop Block Grant.

He has applied for more funding through other sources to continue his project for another three years, during which he plans to fine-tune the accuracy of the infrared gauge, test the sturdiness of his system in the face of mechanical pruning and harvest, and find the optimum angle for his emitters. In his 2018–2019 trials, the 45-degree tilts of his misters sent too much moisture onto the vineyard floor, where it’s wasted, he said. Chang also plans to add a growth chamber element to refine his 95-degree risk threshold.

Using water to cool grapes is a tough sell to wine grape growers, said Kade Casciato, vineyard manager for the Ciel du Cheval Vineyard on Red Mountain, which does employ cooling on a few key blocks.

“People are very, very, very scared of powdery mildew, and rightfully so,” he said.

However, excessive heat on grape clusters can affect their flavor profile and degrade anthocyanin, the compound that gives grapes their color and one of winemakers’ primary quality indicators. There comes a point in a long heat wave where those risks outweigh that of powdery mildew.

Ciel du Cheval already knows how to mitigate powdery mildew risk with its own microsprinkler system that’s installed above high-value blocks of Cabernet Sauvignon and Nebbiolo, an Italian variety sensitive to sun and heat. If a heat wave lasts seven days, Casciato just turns off his microsprinklers — connected to an app on his phone — for a day to let the heat kill off the pathogen.

Casciato suspects Chang’s mist set-up will do more than just save water over microsprinklers. He envisions the system connected to fertilizers and sprays, and fitting well with more smart, sensor-driven technology in future vineyards.

“It’s an awesome idea,” he said. •

—by Ross Courtney

Related:

—Cooling off grapes

Leave A Comment