Tree Top, like any other food producer, faces shifting demands from consumers who want products that are low-sugar, locally sourced, portable and produced in an environmentally sound manner.

So, the Selah, Washington, grower-owned processing cooperative has plans to meet those demands. That means thinking beyond juice concentrate, the bread and butter of the processing market, said new CEO Craig Green at the Washington State Tree Fruit Association’s Annual Meeting in December in Yakima.

“We’ve got to move up the value chain by diversifying our portfolio,” said Green, a longtime agricultural accountant who took the helm in July 2021 to replace the retiring Tom Hurson.

Tree Top considers itself a local company that buys local fruit but competes in a competitive, global market, namely against South American producers. It also works with multinational brands such as Nestle and Kraft, while sporting its own $1 million-per-year research and development department.

At the conference, Green outlined many of the company’s new and upcoming products, some processing facility changes and some existing products that use Tree Top’s fruit in ways you may not expect.

Among the new products is a protein drink made from fruit puree and either soy or brown rice protein. It’s due out this year. Last year’s new products included a low-sugar brand of juice called Fruit + Water, which is half juice and half water. The company started with small pouches but ramped up to meet demand.

“It was so popular, we quickly pivoted and offered it in 64-ounce size as well,” Green said. “And this product is doing really well.”

Also last year, Tree Top launched SunSmash, a hard seltzer that uses real fruit as flavoring.

The company also recently began making pumpkin flakes or powder for use as ingredients in both human and dog food. Tree Top would like to process more berries and vegetables and would prefer to buy them from Northwest growers. Existing equipment can easily pivot to handle vegetables, he said.

Speaking of ingredients, Tree Top’s show up in unlikely places. The company formulated the fruit flavoring for Bud Light’s canned vodka, Pepsi’s KeVita brand of kombucha, Pop Tarts and the organic sweetener for Dave’s Killer Bread. And, for a limited time this year, kids’ meals at Panda Express will include Tree Top apple chips.

Tree Top will continue to make concentrate, but higher-value products benefit the whole industry, said Travis Allan, a member of Tree Top’s board of directors and director of tree fruit at Allan Bros. Inc. in Naches. Tree Top is the largest single purchaser of Washington fruit, so other buyers often take their cues from the company when setting prices. Also, even cull fruit has grades that match up to different products. Juice is at the low end. Sliced apples require a higher grade and, therefore, higher price.

“It’s pretty important that Tree Top makes more money and returns it to the growers, and to recapitalize the business,” Allan said.

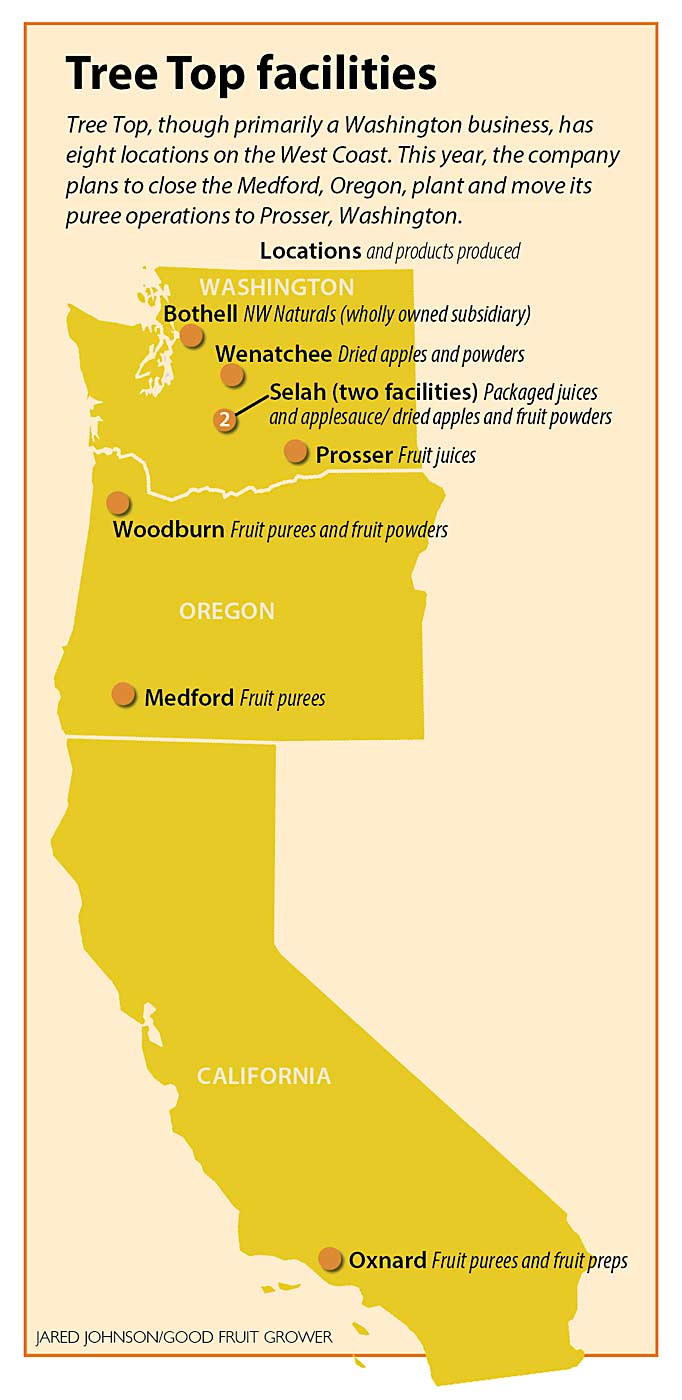

The co-op intends to do that through changes in its processing plants. That included increasing the applesauce pouch capacity in Selah in August last year. In 2022, the company plans to close the Medford, Oregon, facility and move its puree production to its Prosser, Washington, plant, which has idle capacity. The company will still buy all the fruit previously destined for Medford, but it had to improve efficiency, Green said.

“Medford is so far away from the growing regions in Washington, we spend millions and millions and millions of dollars every year shipping apples and pears to Medford,” Green said. “And freight’s not going down, as we all know.”

The changes and improvements come after some hard work to increase company efficiency and improve finances, Green said.

In the past three or four years, the company has improved top line sales by 20 percent, working capital by about 40 percent and EBITA margins — profit share compared to revenue — by 130 percent, mostly through a 15-percent drop in operating expenses.

“Tree Top has had a couple tough years,” he said. “It’s behind us. It’s in the rearview mirror now. Now we’re working on: ‘Where do we go from here?’”

—by Ross Courtney

Leave A Comment