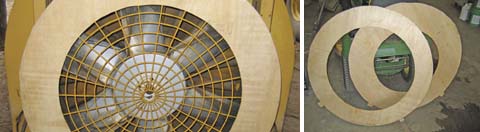

Wooden donuts attached to airblast sprayers are being used to reduce air in-take in field trials as Oregon State University researchers look for ways to minimize drift during delayed dormant spraying.

Photos courtesy of OSU

With goals of minimizing spray drift and maximizing spray coverage, an Oregon State University scientist is looking at a variety of spray and nozzle technologies, as well as application techniques.

Drift from chemical sprays is generally thought of as an environmental problem, but it’s also an economical one. Sprays are expensive-growers don’t want to waste unnecessary material that doesn’t reach the intended target.

Dr. Nagarajan Ramalingam, biosystems and agricultural engineer at OSU’s Mid-Columbia Agricultural Research and Extension Center in Hood River, is studying different spraying-related issues, from sprayer efficiency to equipment comparisons to nozzle design as he works to improve sprayer applications for the tree fruit industry. After joining OSU last summer, he quickly began drift research, conducting preliminary air drift and sprayer field trials.

Drift management is an important issue, he said, adding that research shows that much of the spray material applied by growers can end up wasted on the ground. Ramalingam’s drift management research is funded by a grant from the U.S. Environmental Protection Agency.

Calibrating sprayer equipment is one way to make sure spray applications are at maximum efficiency. Nozzles should be annually checked for wear and tear and replaced when needed.

Many types of sprayers are available, Ramalingam said. Some completely recapture material, others are electrostatic, and new nozzle technologies are changing droplet size for better drift management. In the future, intelligent sprayers will be able to vary the rate and direction depending on tree size.

“With orchard sprayers, it’s not one package fits all because there are so many factors involved-density of canopies, timing, wind, and tree size.”

Drift management

Airblast sprayers are commonly used for orchard spray applications. While orchards change significantly during the year, going from dormancy with no leaves to full canopies, the sprayer technology is the same, he explained.

Obviously, when the orchard has more canopy, better coverage is needed. But is there a way to respond to the needs of bare trees that have less canopy?

“If you can reduce the air intake to the sprayer, can you reduce the sprayer velocity for dormant applications?” he asked. To find out, Ramalingam set up a field trial to see if reducing air intake would reduce drift and save on the amount of chemicals used.

With the help of OSU’s Dr. Paul Jepson and Dr. Andrew Landers at Cornell University in New York, Ramalingam designed plywood “donuts” to attach to the outside of an air blast sprayer to reduce air intake. Different sizes of donuts were also tested.

Chemical sensors placed at different locations and in rows beyond the application site were used to track where the sprayed material was going. A tracer was put in the chemical so that even small amounts could be measured.

Ramalingam also studied two types of spray technologies, an airblast, which sprays material up and out, and Proptec, which directs spray horizontally with more uniform spray droplets. Placement of fans on the Proptec can be adjusted depending on boom height.

In his studies of the airblast sprayer without the wooden donuts, the tracer chemical was found deposited on leaves as far out as the eighth row, he noted, adding there is a wide variation in droplet size with the airblast. But when the donuts were attached, he found a significant reduction in the distance where the tracer was found, with material detected one or two rows from the application row.

“With the donut, it

He noted that the Proptec is different technology than the airblast sprayer and must be used under appropriate conditions and calibrated properly or there can be drift potential. “The droplets are more uniform in size than the airblast, varying from 80 to 120 microns, but if it’s used in the wrong circumstances, under windy conditions or the fans are not at the proper angle, there is potential for drift.”

Future studies

Ramalingam hopes to continue looking at ways to minimize drift and maximize spray coverage, as his first-year studies are preliminary, and much more work in the area of drift management is needed.

One of the areas he believes that needs to be addressed in the future is the impact that high-density plantings have on spray volumes.

He is interested in research done in Australia that found significant differences in spray rates between high density and conventional spacing in vineyards.

“It’s not just pounds per acre anymore,” he said. As the tree fruit industry moves to high-density plantings and solid planes or walls of fruit, he foresees a new way of determining how much material should be applied that may depend on factors like canopy uniformity, tree maturity, dormancy versus blossoms versus full canopy, and row spacing.

He plans to continue his drift research, conducting more delayed dormant spray trials and evaluating the biological efficiency of the spray applications.

Leave A Comment