A trellis collapse comes down to two factors — a soil failure or a material failure. (Courtesy of Mark De Kleine)

After a yearlong review of trellis failures in Washington apple orchards, an engineer has created a tool that growers can use to calculate loads in orchard systems to better design trellises and prevent failures.

In order to remain standing, trellis systems must be built to withstand the balance of forces above ground — wind, canopy type, anticipated fruit load, wire span and the superstructure, including shade cloths or netting — and the soil type and foundation below ground.

A grower survey found that 90 percent of trellis failures occurred in fairly new trellis systems, those built within the past 10 years.

“This isn’t necessarily a fatigue issue; it’s an engineering problem,” said Mark De Kleine, an agricultural engineer for specialty crops with De Kleine Machine Co.

The new tool, called TrellX, aims to make the process of designing and engineering a trellis more straightforward for growers.

“So often, I’d visit a grower and ask how they came up with, say, the distance between posts, and they’d say, ‘Hmm, it just looked right,’” De Kleine said. “And when we’d figure out their loads and come up with the trellis design, they’d be really close. Their instincts are close, but not perfect.”

But as growers move into more modern systems that are higher density and higher yield, trellis systems require additional engineering and expertise, said Karen Lewis, a Washington State University tree fruit regional extension specialist who assisted on the project.

“Most trellises are going to stand just the way they are,” she said. “But because we’ve had this void or gap in knowledge, some trellises have been overdesigned and some have been underdesigned. Let’s just apply more knowledge to the design and installation.”

Diagnosing and preventing failure

There are two types of trellis failures: a soil failure, which would result in an overturned post, and a material failure.

“A soil failure becomes very difficult to predict from an engineering side, and if your post isn’t in the ground deep enough, then moisture becomes an issue, too. As soil becomes more saturated, it actually starts to act like a liquid,” De Kleine said.

Growers know their soil better than anyone else, and there’s likely some variation, said Paul Booker, a mechanical engineer and co-researcher with Steep Consulting who also farms full-time south of Othello, Washington.

The north end of the orchard may have more rock, and a grower will be hard-pressed to get a post installed, while the south end may have some fill, making installation easier. “The trick is, you have to optimize,” he said. “You want to take that variability out of it.”

Meanwhile, a material failure, from an engineering standpoint, is good news, “because we can relate the above-ground forces to the material strength,” De Kleine said. “It’s not good to see a failure, but in this case, we can combat it with bigger or larger materials or stronger materials.”

There are also two types of posts: constrained and nonconstrained. Shallow soil should be combated by adding restraints either above ground, at the ground level or below ground, effectively increasing width and strength.

“A fixed post puts the material to work. If you can embed the post, and put all of the forces on the material, that’s a good thing,” he said. “But critical depth is layer dependent. You need to understand your soils. Nonuniform soils have a different depth requirement than uniform soils.”

In general, for 3- to 6-inch wood posts, in sandy soil, growers should approximate needing to install the post to a depth that is equal to roughly

30 percent of the post trellis height. A 12-foot trellis, for instance, would need to have 4 feet of each post in the ground. “Bedrock, as that soil gets stronger and more rocky, you need generally less, about 20 percent,” De Kleine said. “If in doubt, have some soil tests done.”

Each post must also support a representative portion of the load in the trellis, as well as the wind load and fruit load. As a general rule, he said, growers should avoid growing fruit above the trellis.

“If you’re going to grow fruit up top, please trellis up there,” he said. “It will make things a lot easier.”

In addition, a conservative estimate for post spacing is 20 feet for a sandy soil site with a high wind estimate of 60 mph. The survey showed that the majority of trellis failures reported, 60 percent, had posts spaced at greater than 40 feet.

TrellX

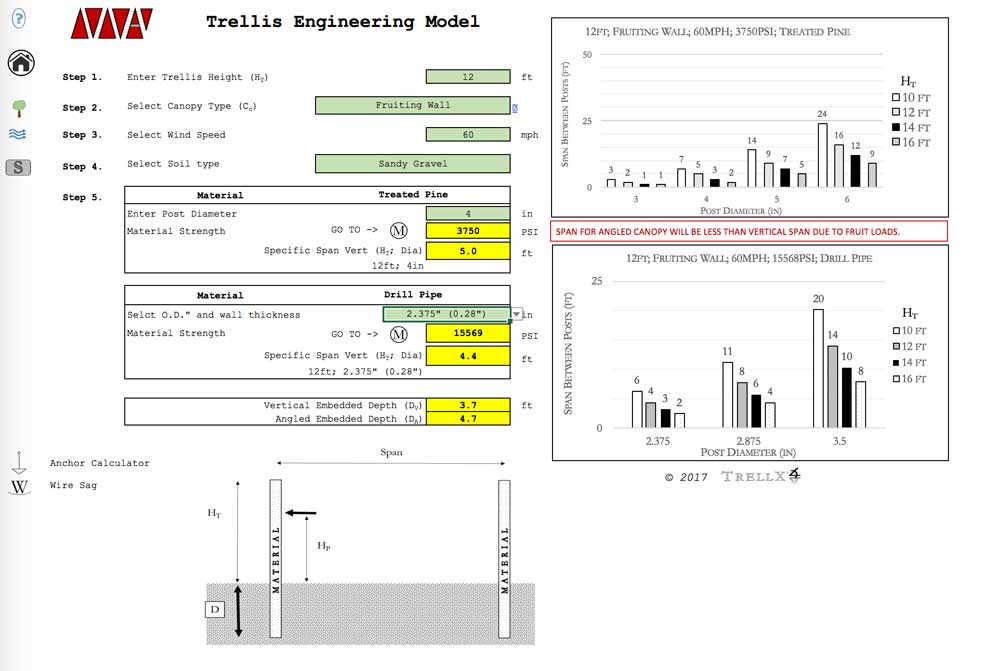

The TrellX tool, a series of worksheet pages, like this above, that can be filled out on a computer, offers guidance to design and engineer a trellis.

Generally, the survey showed that trellis type was not a factor in failures; half of the reported failures were in vertical trellises, the other half in angled trellises.

That’s why growers need to take steps to design and engineer the trellis for the location, type of system and crop load they want, De Kleine said.

The free TrellX tool has dropdown menus to select variables that will influence trellis design — height, canopy type, wind speed and soil type — to determine the recommended embedment depth for posts and suggested span.

Additional screens provide educational information about canopy types, wind and soil. The tool also includes calculators for elasticity (psi) for treated pine and drill pipe and for pound-force required for anchors.

The Washington Tree Fruit Research Commission provided $92,500 for the project, and Washington State University provided assistance. The tool can be found at www.trellx.com. •

– by Shannon Dininny

Leave A Comment