The McDougall family jumps at opportunity.

They were one of the first to invest in proprietary varieties; they were an early adopter of the H-2A labor program; and it wouldn’t be an industry tour in Washington without a visit to their orchards or state-of-the-art packing house to talk about innovation.

“They’ve always looked for a better way to do things, and they are always open to sharing their learning with others,” said Bob Mast, president of CMI Orchards, the marketing company McDougall and Sons co-founded.

For example, in 2015, the McDougalls opened their new Baker Flats packing house to the industry for cleaning and sanitation workshops, at a time when it was “fairly unheard of for packers to open their doors to other companies,” said Kate Tynan, senior vice president of the Northwest Horticultural Council, which helped to organize the industry’s response to the listeriosis outbreak in caramel apples.

“As they so often do, the McDougall family led the way,” she said. “Providing an opportunity for employees from throughout the industry to learn important information and, just as importantly, making other companies feel comfortable opening their doors to host demonstration workshops.”

The McDougalls have always been willing to welcome researchers to their orchards, said Tom Auvil, who coordinated many of those trial plantings when he was with the Washington Tree Fruit Research Commission. But even more importantly, “Scott’s been extremely helpful in sharing the economics of what they do, and why,” Auvil said. “He can take those results from a trial and say, ‘This is the impact on our business.’ That kind of frankness and ability to share has made them a great resource.”

Scott McDougall, company president and longtime leader of the orchard side of the business, said hosting the industry, for trials or tours, has always been his way to give back.

“I’ve really flown my own ship here, and I’ve not been that active on boards or anything else,” he said. “I just thought, this is my turn because I love being out in the orchard and I love the horticultural aspects of it. And it’s nice to be able to hopefully help other growers to prevent some of the mistakes that I’ve made.”

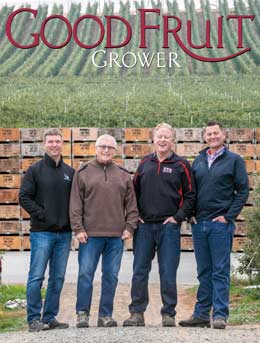

That willingness to share, paired with their passion for innovation in both the orchard and packing house, is why the McDougall family has been selected as the 2022 Good Fruit Growers of the Year. The award is bestowed annually by the magazine’s advisory board and will be presented at the Washington State Tree Fruit Association Annual Meeting in Wenatchee in December.

The family’s generosity with the industry and wider community was also recognized, as they’ve supported parks and other community efforts in Wenatchee, helped the Washington Apple Education Foundation pioneer its mentorship approach and served on industry boards, including the Washington State University endowment committee and the Northwest Horticultural Council.

Now, the “sons” in McDougall and Sons, Scott and Stuart, are proud to see their own sons helm the orchard and packing company that’s grown to become one of Washington’s most innovative operators.

While Scott and Stuart are fourth-generation growers, they founded McDougall and Sons with their father, Bob, when they returned to Wenatchee after college. Stuart’s son, Bryon, joined the business almost 20 years ago, working his way up to serve as company vice president after Stuart retired. Scott, president, continues to lead the orchard operations; his son, Matt Jeffery, began working for the company in 2017 and now serves as assistant manager for the company’s 4,000 acres of orchards, balancing the family business with running his dental practice.

“My brother and I had this great division of labor,” which made it possible to enjoy working together, Scott said. Now, he and Stuart look forward to Bryon and Matt sharing the same balance for decades to come.

“We work more closely together,” Bryon said. “With the complexity the market has in the varietal mix and packaging mix, that requires tighter communication between the orchard and the warehouse today.”

Building a family business

While the dentist-to-orchardist route is unusual, Matt said bringing a different perspective to the business has its benefits.

“I’m like the 3-year-old in the group, always asking why,” he said. “I’m always looking for ways we can be more efficient.”

In fact, Bryon is the first member of the McDougall and Sons family who knew he wanted to be in the fruit business before he graduated from college. He worked on a new cherry line as a summer job, he said, and “from that point forward, I started developing a passion for the industry.”

His grandfather, Bob McDougall, envisioned a career in journalism but started working for his father-in-law’s orchard business, Horan Bros., in the late 1940s. Eventually, he took over the business, juggling it with serving 12 years as a state lawmaker.

Stuart and Scott both studied political science in college, and Stuart recalls returning after graduation to help his dad until he decided on a “real job.” Scott graduated in 1975, and in 1976 they combined Bob’s small packing shed with the Horan orchards to create McDougall and Sons.

“We started out small,” Stuart said. He and Scott had to learn every aspect of the business — and they grew as it did. They would pitch plans to their father, who would reply, “That’s a great idea. Do you have the money for that?” Stuart recalled.

Stuart took on the warehouse side of the business while Scott assumed oversight of the orchards, and both credit the ability to “stay in our own lanes” for their success working together.

“Scott and I, we persisted. We liked Wenatchee and we had our families here and we persisted,” Stuart said.

The first big leap for the company came in 1989, when they were invited to partner in CMI. That partnership, “with really dynamic sales guys,” gave them more insight into the global market, Stuart said.

Still, it wasn’t easy being a small warehouse in the ’90s. The future looked uncertain, and Scott encouraged Matt to take his love of science into a different path, which led to dental school.

In the early 2000s, Ambrosia changed everything.

“We gambled, but we had to do something to make us survive,” Stuart said. “The Ambrosia apple brought us to where we are.”

New apples, new opportunities

The second time they tasted an Ambrosia, freshly harvested in the fall, Stuart and Scott decided to make a bid for the apple, which had been discovered by a British Columbia grower and later commercialized by the Okanagan Plant Improvement Co. In 2004, McDougall and Sons won the exclusive rights in the U.S. market and began exploring how to grow and handle it.

Slowly, they built the program and the demand.

In 2005, the McDougalls were one of the first growers to partner with ENZA to grow the New Zealand company’s varieties in Washington as well. “Scott has always been on the leading edge,” said Rick Derrey, who managed ENZA’s U.S. program.

“They were the first risk-takers in our industry to look at proprietary varieties,” CMI’s Mast said. “They made a huge investment in Ambrosia. They jumped in with both feet and got serious about planting it. They’ve always been a family that, when they make up their minds, they go all in.”

Yes, it cost a lot of money to invest in those varieties, and plant them at scale, but Scott said they learned it’s better to take risks and invest in change when you are making money.

“Those kinds of prices allowed us to think differently,” Stuart said. “We still weren’t a big company, but we went from there.”

Bryon joined the business after college in 2003, at the dawn of a new era, with expanded plantings of new varieties that then required new storage and packing capacity. He worked his way up through a variety of roles, starting with a tray line at a packing facility that McDougalls and Columbia Fruit Packers co-owned, and then at a pear packing shed they had recently purchased in Monitor.

“There’s nothing better than having people in the industry telling you how much they respect your son,” Stuart said of Bryon. “He came on as our business was starting to change, and he moved up fast. When you are growing like that, there’s opportunities without stepping on any existing employees’ toes.”

By the 2010s, Bryon was taking on more leadership.

“Somewhere around 2014, my dad started scaling back and spending more time working with CMI and sales and growth strategies,” Bryon said. “I assumed the role that he had, slowly, because as we grew, he needed somebody to be more focused on operations.”

Around that time, Bryon took the lead on designing the company’s new facility at Baker Flats, north of Wenatchee, to handle the production from all of Scott’s new orchards. It started with storage and shipping capacity, but investing in a new line gave them an opportunity to integrate modern food safety technology, increase efficiency and improve the worker experience with tall windows that flood the space with natural light.

“We still argue over whose idea it was to do those big windows,” Stuart said.

Bryon said his vision was to build a space that would adapt to the future, first with the apple line in 2014 and then the cherry line next door in 2015.

“Certainly, it was overbuilt,” he said, looking at the space awaiting an additional apple line someday (see “Putting packaging first”). “But I was thinking, ‘What am I going to need 10 years down the road?’ We always end up adding and expanding and using up space.”

Legacy

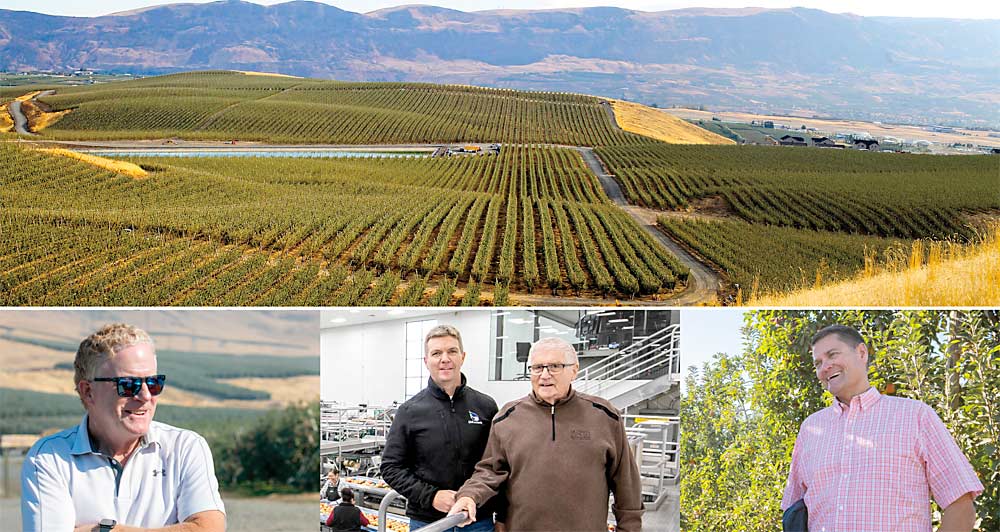

Consumer demand and premium returns enabled the McDougalls to launch a rapid era of expansion, first in the Columbia Basin and then at their signature site, Legacy Orchards, a picturesque spot on the eastern hills overlooking the city of Wenatchee.

In 2012, they bought the 830 acres of former dryland wheat ground with water rights, designed a plan to pump water up over 1,000 feet from the Columbia River, and started planting a year later. Today, Legacy Orchards includes 550 acres in production, about half of which are organic, planted in Gala, Honeycrisp, Ambrosia, Jazz, Fuji, Cosmic Crisp and Envy, with 40 acres of cherries.

“It’s one of the nicest orchards in the industry,” said Mast, who frequently takes retailers to the viewpoint at the top. “They don’t cut corners. Legacy is a testament to that.”

Auvil recalls the planting precision the McDougall team developed during those years, which he experienced firsthand when they planted a cherry rootstock trial for the research commission with a GPS tree planter and crew, immediately followed by an irrigation crew laying drip tape.

“It was amazing how they could go from a grassy field one afternoon to a planted orchard the next,” he said. “They had the water on before we were done planting.”

Scott takes obvious pride in the orchard, so much so that he recently built his own home on one of the property’s viewpoints. Though Matt is assuming more of the management, Scott isn’t yet ready to step away from his passion for horticulture. “I don’t see myself going anywhere, because I love to learn,” he said. “You never stop learning, that’s what makes this business fascinating.”

His house sits not far from the farm’s 144-bed, H-2A housing complex. The McDougalls started working with H-2A in 2009, because they saw the program as insurance they couldn’t forgo while investing in new plantings.

And they don’t cut corners with investments, either. The housing area is landscaped. The roads are paved. The windows make the packing house a nicer place to work.

“I have always said, your orchard is like your backyard,” Scott said. People see the pride put into it, and it makes them proud to be a part of it, too. “That approach runs through our whole process.”

If there’s a moral to the McDougalls’ success story, it’s that a proactive approach pays off. Times are tough, but the fruit industry can’t pause to just wait it out.

“We face a lot of challenges with exports and logistics and the rising cost of everything, not to mention Mother Nature,” Scott said. “So, we can’t afford not to be firing on all cylinders.”

“In order to survive and thrive and have the business strong for the next generation, we have to come up with ways to save ourselves money,” Bryon said. “We’ve tried to position ourselves by looking at things a little differently.”

—by Kate Prengaman

Leave A Comment