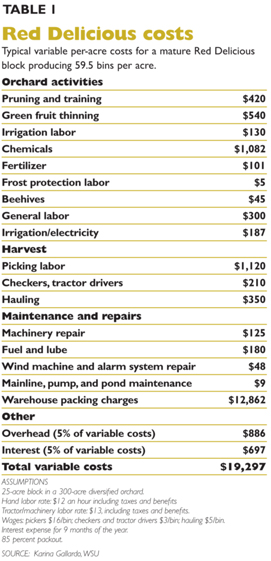

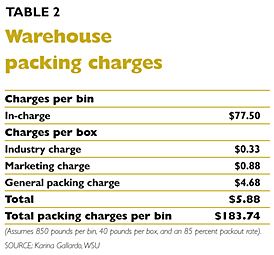

A new economic study from Washington State University estimates the variable costs of producing Red Delicious in a mature orchard at $6,436 per acre and fixed costs at another $2,804. On top of that, the grower would pay $12,862 in packing charges, assuming a net yield of 59.50 bins per acre (culls removed) and a packout of 85 percent.

A new economic study from Washington State University estimates the variable costs of producing Red Delicious in a mature orchard at $6,436 per acre and fixed costs at another $2,804. On top of that, the grower would pay $12,862 in packing charges, assuming a net yield of 59.50 bins per acre (culls removed) and a packout of 85 percent.

With an f.o.b. price of $400 per bin (before packing charges are deducted), the estimated net profit would be $1,698 per acre.

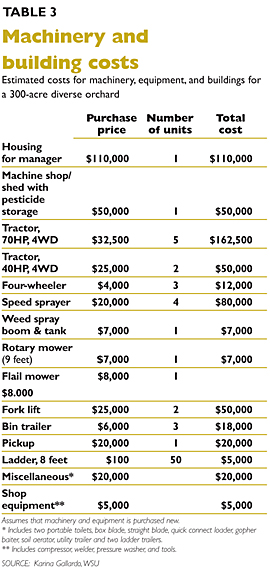

The costs are based on a hypothetical 25-acre block of Red Delicious within a 300-acre diversified orchard. Trees are on Malling 106 rootstocks and are spaced 4 by 12 feet apart (900 trees per acre). The life of the orchard is estimated to be 30 years. The amount of capital required in the year of planting is almost $550,000 for the block.

The study’s author, Dr. Karina Gallardo, estimates that the planting would produce 12.75 bins per acre of packable fruit in the third year, 25.5 in the fourth year, 42.5 in the fifth year, and 59.5 bins each year thereafter.

The labor rate is assumed to be $12 per hour (including taxes) for hand labor and $13 for tractor and machinery operators. The picking rate was assumed to be $16 a bin.

Gallardo said growers who are only able to cover their cash costs (variable costs) cannot be financially stable in the long run, because sooner or later they will need to buy equipment or modernize the orchard.

Gallardo did a similar study for Honeycrisp apples last year, which showed a potential profit at $6,464 per acre, based on a net yield of 43 bins per acre and an f.o.b. price of $650 (before packing charges are deducted).

Costs for thinning, chemicals, fertilizer, picking and hauling, and machinery repair were all higher for Honeycrisp than for Red Delicious, resulting in variable costs totalling $7,262 per acre. Fixed costs were significantly higher across the board for Honeycrisp and totalled $4,211 per acre. However, packing costs were lower ($10,014 per acre) because of fewer boxes packed per bin.

Dale Goldy, assistant general manager with Stemilt Ag Services, said Red Delicious are a lot more forgiving and produce more consistently than other varieties, but some of the lower production costs are offset by additional expenses for the harvest management tools ReTain (aminoethoxyvinylglycine) and Harvista (preharvest MCP treatment).

The full economic study and an Excel spreadsheet of the enterprise budget for Red Delicious, as well as data underlying the calculations, are available at the WSU School of Economic Sciences Extension Web site at http://extecon.wsu.edu/pages/Enterprise_Budgets. Growers can modify certain values and use the Excel Workbook to evaluate their own production costs and returns.

Leave A Comment