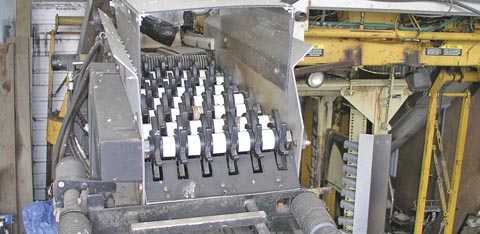

The mog remover, owned by Jerry Czebotar, is a series of spinning rubber star wheels attached to the top of the grape harvester’s conveyor belt that delivers grapes to the gondola. A similar concept is used on potato harvesters. (Melissa Hansen/Good Fruit Grower)

A sorting device that can be attached to mechanical grape harvesters is finding renewed interest in the juice grape industry, particularly in Washington State, which holds the distinction of having the highest minimum wage rate in the country.

The implement, called a mog remover or demoger, removes material other than grapes known as mog and has been used in East Coast juice grape vineyards for several years, though just recently in Washington.

Jerry Czebotar, grape grower from Pasco, Washington, saw the mog remover in Michigan several years ago and was so impressed with the attachment that he called the president of one of the grape harvester manufacturers as soon as he returned home to learn more about it.

Czebotar learned that the demogers had been available for years, but had never been especially popular nor taken off in Washington.

Now that he’s used one for two seasons, he swears by it and wouldn’t consider harvesting juice grapes without it.

“It’s so simple. I’m surprised that it took us fifty years to figure it out,” he said.

Mog removers can be custom built or they can be purchased from grape harvester equipment dealers, he added. The concept is similar to a potato sorter, with a series of rubber star wheels spinning in the same direction. The grapes fall down through the star wheels to the gondola while the rocks and debris are kicked out to the ground.

“If you are picking any amount of grapes, it will pay for itself in labor savings within two years, and in one fall in liability savings.”

Czebotar typically harvests about 200 acres of juice grapes each fall, including his own.

Before using the demoger, he paid a bin attendant to ride on the harvester to inspect grapes and remove rocks, sticks, and other debris as fruit moves across the conveyor belt into the gondola.

“You’ve got a guy hanging on the outside of a little crow’s nest that you’ve built for him,” he explained. “It’s not comfortable, and it’s cold at night. Now, I can run the harvester with only two guys.”

Czebotar believes that with minimum wage rising annually in the state-at $7.63 this year-the mog remover makes more economical sense than it did in the past.

“And with National Grape

Mike Concienne, area manager for National Grape, the processing arm of Welch’s, noted that the cooperative studied the attachment in Michigan vineyards to make sure it would do the job as claimed by manufacturers. After testing, the mog remover received its stamp of approval.

“We like it because it does a better job of removing mog and is continuous and consistent. Also, it reduces worker liability,” he said. One of the benefits is that harvester operators don’t have to worry about the bin attendant being distracted.

“I couldn’t sit up there like they do. Watching grapes continuously go by on a conveyor belt would make me dizzy.”

Concienne is seeing more and more people use the attachment because it does a better job of quality control. “The costs are a little spendy, but with minimum wage and liability costs rising, the economics of it make more sense.”

Wine grapes

The one drawback to mog removers is that they don’t work well on wine grapes that pick as clusters. If the berries don’t fall off the clusters, the star wheels kick the whole cluster out as if it were debris.

Jack Maljaars of Vine Tech Equipment in Prosser, Washington, said that a mog remover will be out this season to accommodate wine grapes and clusters. The angles of the sorting wheels are adjustable to help break up large clusters and keep the fruit from being kicked out.

Another new feature will allow the operator to easily disable the mog sorter by pulling a few wheels out.

American Grape Harvester makes a demoger, as well as other grape harvester manufacturers, he said, adding that other new attachments to grape harvesters designed for wineries are available to de-stem grapes and remove petioles. Petioles, which are the stems of the leaves, can be more difficult than leaves to remove because there is no surface area to blow or pull out.

A factory-ordered mog remover, installed, costs around $8,000, according to Maljaars. Some growers and custom harvesters are building their own units. He knows of eight juice grape harvesters in Washington that have mog remover attachments.

“It’s not new technology or high tech,” he said. “But there seems to be new interest in the equipment, largely being driven by rising minimum wage rates. It’s a replacement for the guy sitting there who physically removes mog. And it’s been approved by the processors.”

Leave A Comment