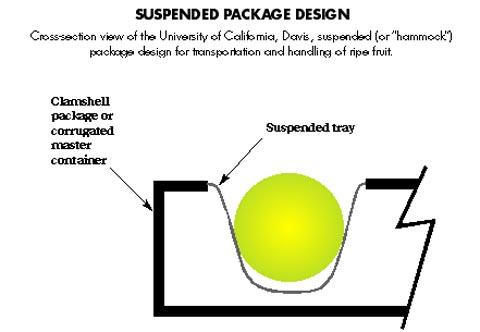

A newly developed suspended tray package (Hammock pack) is capable of protecting ripe Bartlett pears from transport vibration damage. The system can be designed for a consumer clamshell package or larger corrugated master container for foodservice applications.

A newly developed suspended tray package (Hammock pack) is capable of protecting ripe Bartlett pears from transport vibration damage. The system can be designed for a consumer clamshell package or larger corrugated master container for foodservice applications.

Ripe pears outsell green fruit by more than three-to-one in retail markets. But ripe fruit soften quite quickly at room temperature and are very susceptible to surface bruising. The bruising can be caused by transport vibration, rough handling of boxes at wholesale or retail distribution, and by consumers inspecting fruit on display. The bruises on ripe fruit quickly turn dark brown reducing the visual appeal of the fruit. The pear industry and the consumer would greatly benefit from a package that would protect ripe fruit from bruises sustained in transportation, handling, and retail display.

During the past 15 years, we have developed a good understanding of the physical causes of transport vibration bruising. It is greatest in the top boxes of pallets loaded in the rear of a trailer. Air ride suspension greatly reduces damage and packing fruit in polyethylene bags also minimizes damage to mature but not ripe pears. However, ripe fruit that has begun to soften below 12 to 15 pounds firmness is very subject to damage even with best possible handling.

Procedure

The goal was to develop a packaging system that protects pears from bruise damage and test its effectiveness of the suspended tray in protecting pears from transport vibration damage.

We developed a package called a suspended-tray pack (sometimes called a ³hammock pack²) that better protects soft fruit from vibration damage. Commercial prototypes of the tray were manufactured by the FDS Manufacturing Company, Inc., of Pomona, California, and were used in the test. The system can be designed for a consumer clamshell package or larger corrugated master container for foodservice applications. The following packages were placed on a computer-controlled vibration table and subjected to 30 minutes of vibration, designed to simulate the worst 30 minutes of travel-the roughest roads, most potholes, and such-in a cross country trip.

Three packages were studied in the research:

1) UCD suspended tray clamshell with 6 pieces of fruit per clamshell, 8 clamshells (2 layers) in a Euro-standard box;

2) Conventional clamshell with 8 pieces of fruit per clamshell, 6 clamshells (2 layers) per Euro-standard box; and

3) Standard 2-layer tray pack in a corrugated box.

Before placing the fruit on the vibration table, the fruit was allowed to ripen at room temperature to differing firmnesses. Immediately before the vibration test, the firmness of each piece of fruit was measured with a Sinclair nondestructive firmness tester. After the vibration test, the fruit were held for a minimum of 24 hours at room temperature to allow any firm fruit to soften below 10 pounds penetrometer firmness so bruises would become evident.

Eighty pieces of fruit from the three package treatments and a nonvibrated, nonripened control were scored for bruise damage. Damage was expressed using the 0 to 5 point Mitchell transit bruising scale. A score of 0 means no bruising damage, a score of 3 is enough damage for a consumer to consider not buying the fruit, and a score of 5 is a fruit with damage over its entire surface.

Results and conclusions

The UCD clamshell protected soft fruit from damage much better than either the standard two-layer tray or the conventional clamshell. At estimated penetrometer firmness levels less than six pounds, the bruise score was just above 1 for the new clamshell. This means that the fruit sustained only slight damage that would not be noticeable to most consumers.

Soft pears in the standard tray had bruise scores near 3, meaning that bruises were visible on over half the fruit surface, and a consumer would seriously consider not buying the fruit unless it were discounted in price.

Soft fruit in the conventional clamshell had a bruise score near 4. Damage was visible on over three-quarters of the fruit surface, and it was unsaleable. Many fruits in the conventional clamshell were cut where the fruit touched the plastic near the junction of the top and bottom sections of the clamshell.

We did not evaluate damage that may occur at retail display, but the two clamshell packages prevent consumers from sorting through fruit on display and squeezing it. Fruit shipped in conventional trays is usually displayed in bulk and subject to damage on display.

The suspended tray clamshell pack (Hammock pack) is capable of protecting soft, ripe Bartlett pears from transport vibration damage. Pears shipped in either the conventional clamshell package or the standard tray pack should not be softer than a penetrometer firmness of 12 pounds to prevent transport vibration damage.

Leave A Comment