Kameron and Kerry Miller know their pear orchards need renovation to increase production and improve the efficiency of labor and pest control, but prices that have fallen below the cost of production make any sort of investment risky.

“Right now, we’re just making enough to trade dollars. We’re not making money,” Kerry Miller said. In the Dryden, Washington, area, he is removing steep-slope blocks that he plans to replant slowly, a few acres at a time. “I’d be financially ahead to just knock it down and not replant with the way things are right now,” he said.

At $300 a bin, they could make it, his brother, Kameron, said of the 260 acres they farm. But at $250 or even $225 in recent years, “you can’t keep up your equipment, you can’t afford any new plantings,” he said. “That’s the problem we got ourselves into.”

This unsustainable situation — at today’s prices they can’t afford the investment needed to get to more efficient farming that would help them make money — is all too common for pear growers across the Northwest. And for growers looking ahead to retirement, good exit strategies are vanishing.

Kameron Miller sits on the board for his packer, the Peshastin Hi-Up Growers co-op, and he and his fellow board members say they need more collective industry action around marketing and postharvest handling to improve the quality delivered to consumers and drive up prices — or they’ll be out of business. Many of the cooperative’s growers have already sold off orchards to apple growers or developers, said manager Ken Hemberry, himself included.

“As profits decreased, many growers expand to spread costs out, but then when you have more, it’s more to lose,” Hemberry said. The other things that will help prices: reducing production, as much as Hemberry hates to say it. “The math won’t stay where it is, because unfortunately some growers will go out of business,” he said.

Nothing left to cut

Costs just keep going up, the Hi-Up growers said, with labor topping the list. Pest control is another necessity, and you can only delay fertilizer or equipment repairs for so long.

New pest control costs recently hit the Millers’ orchards in the form of invasive squirrels that can strip a block nearly bare from bloom on. He first saw the squirrels three years ago, and his crews now catch and kill over 1,000 a year at the cost of 70 or so $50 traps and one or two hours of staff time every day, he said. It’s another nonnegotiable cost.

“The main battle is that our costs are so high,” said Steve Cowan, another Hi-Up grower. He estimates losing 20 percent a year for the past five years. “I’m in the mode of (spending) as little money as possible right now, but you can only cut so much before you start to sacrifice your returns.”

Agricultural economist Clark Seavert of Oregon State University said pear growers are right to seek solutions in better marketing of their product to drive up prices.

“The No. 1 thing is always the price of the commodity. Trimming costs is not going to save you,” he said. “No. 2, and always No. 2, is yield. Third and always third is cost, but when times get tough, growers cut costs first.”

Selling off orchards can help — Seavert calls it addition through subtraction.

“If you can identify those worse blocks and get rid of them, you can take that money you are investing in those blocks and invest it in others or give yourself more flexibility in your financial structure,” he said. “If you don’t do this, it’s a downward spiral.”

That’s what Hemberry did, selling a farm that was farther away from his home farm and expensive logistically to operate. But for growers looking toward retirement, selling is also a complicated proposition. Hemberry said he’s considering using the proceeds from orchard sales to send his son to trade school instead of preparing to turn over the farm to him, since finances are so bleak.

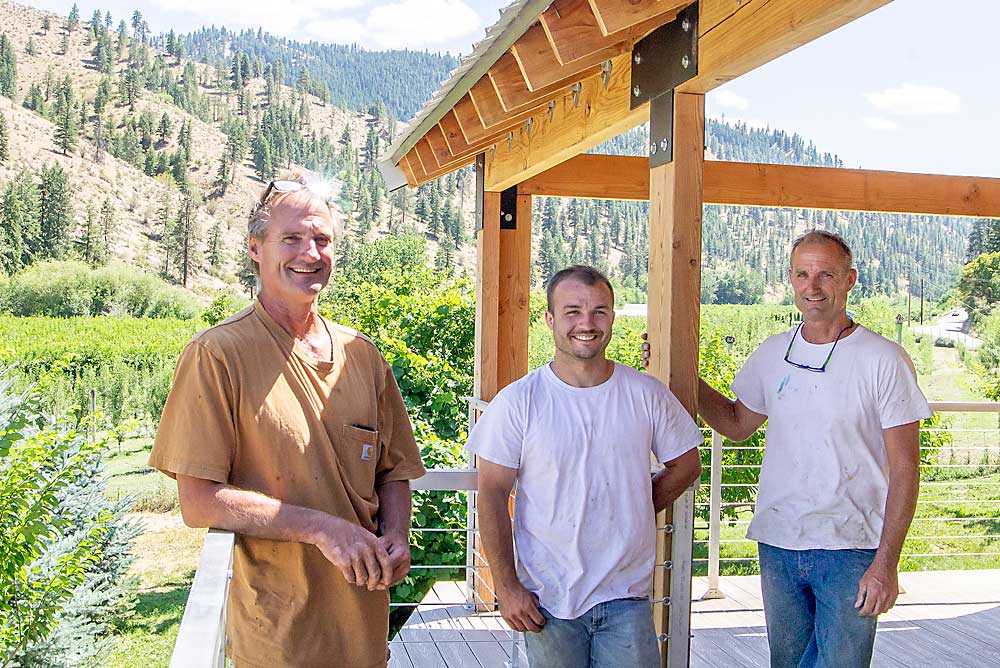

Kameron Miller says his three nephews who work on the farm want to take over the business, but they can’t afford even the operating capital costs on their own right now, and he and his brother can’t afford to offer them the farm at a discount and retire.

“To be solvent, and reaching an age of wanting to slow down, I had to sell land that’s been in our family since 1929,” said Cowan, who’s down to just 33 acres. “I could not in good conscience pass this business on to my son; I would take it to my grave if it set him up to struggle the way we have.”

New plantings

Growers say the challenges of farming orchards planted by their fathers or grandfathers abound, but the alternative — knocking down older Anjou trees and taking out loans to plant new Anjou trees that will take years to grow into production — seems crazy, too, Kameron Miller said.

“We’ve been talking about this ever since we started farming,” he said, waiting for a breakthrough precocious rootstock to justify the cost of renovations.

“It’s not if, it’s when,” Kerry Miller said of the need to replant, which they started several years ago on the budget-driven scale of several acres a year, learning as they go. “Planting is all new to us. We inherited all these headaches.”

For a model, they looked to Rudy Prey, a nearby Leavenworth orchardist and president of the Hi-Up board, who planted his own experimental high-density orchards starting over a decade ago. Instead of installing expensive trellis, he trains two-leader trees and ties the leaders together across the aisles to create a V-system with no trellis. The competition from the dense planting keeps the trees small, even on traditional rootstock.

Keeping the trees shorter and the canopies smaller means better spray coverage and more efficient pruning and harvest, Prey said. His crew likes working in the smaller trees. But he hasn’t planted a new block in six years, because even with the efficiency, he said he can’t justify the $25,000 an acre planting costs.

“I’m getting lower returns now than my dad did 30 years ago,” Prey said. “It’s not worth it.” •

—by Kate Prengaman

Correction:

Hi-Up grower and board member Steve Cowan was incorrectly identified in the print version of this story. Good Fruit Grower regrets the error.

Leave A Comment