Curt Salisbury began the afternoon “Implementing Technology” session at the Washington State Tree Fruit Association Annual Meeting by showing a graphic of a tombstone with the name Abundant.

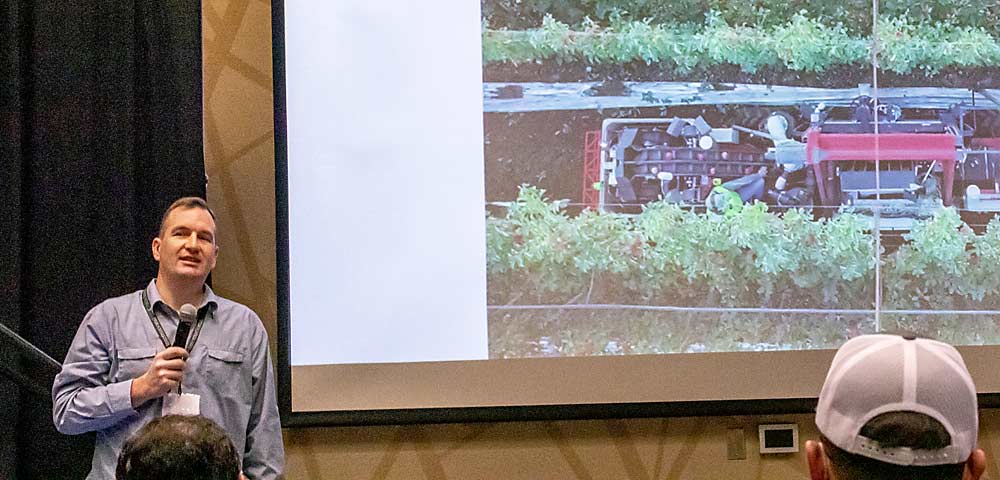

After the dark, self-deprecating joke, Salisbury, one of the founders of Abundant Robotics, then delivered a candid history of the engineering successes but ultimate financial failure of the California company’s efforts to develop a robotic vacuum harvester.

“The simple reason was we ran out of money,” said Salisbury, now a scientist for Amazon.

Abundant was largely considered the frontrunner in the race to commercialize a robotic apple harvester. The company raised a total of $20 million in grants and venture capital since its 2016 inception out of SRI International but needed to raise about $2 million more in revenue to convince investors to stay in, Salisbury said.

After years of trial and error, broken equipment and problem solving, the company’s prototype was able to pick a bin of apples in 66 minutes at a time when there was no other mobile robot that could perform manipulation on the market, said Salisbury, the chief technology officer for Abundant. “And we’re doing it on a farm,” he said.

The goal was 50 minutes per bin at a target cost of $10 per bin.

Salisbury also shared a few insights for the future if someone else nears commercialization on a robotic apple picker. Other companies are still developing prototypes.

—Picking in a 20-inch canopy is twice as expensive as in a 10-inch canopy.

—Consider a competition for a business plan, with a $1 million prize.

—Consider somehow pooling grower money. If the industry would have contributed $5 million, venture capitalists would have invested the rest, he said.

—Robotic fruit harvesting will hit apples first and then spread to pears, cherries and other forms of tree fruit.

Abundant, based in Hayward, California, declared a form of bankruptcy in late June. The company’s prototype and intellectual property has been purchased, though Salisbury declined say by whom.

Salisbury lauded the tree fruit industry’s support, which started with grants totaling about $650,000 over two years from the Washington Tree Fruit Research Commission. The investment not only helped development, it also signaled legitimacy to venture capital investors and introduced the founders to grower-collaborators who patiently let them make mistakes in their orchards.

“I wouldn’t change anything about how this interaction went,” he said.

The Tree Fruit Association owns no part of the intellectual property or equipment.

The technology session Tuesday afternoon also included a presentation about heat stress and mitigation by Lee Kalcsits, a Washington State University tree fruit physiologist. He said trees with higher vigor and deeper roots fared better during the summer’s record heat wave, which runs contrary to other horticultural goals. Cover crops helped keep soil cooler and therefore reduced stress on trees.

He recommended a variety of tools, including netting, protective coverings and fogging. Single methods to mitigate heat stress were not enough in 2021, and such heat stress could become normal in coming decades, he said.

Also, evaporative cooling works best if cycled, Kalcsits said. Just make sure the water comes back on before fruit dries completely.

Other presentations involved discussions of sensors and a grower panel about spacing and design of new plantings.

Leave A Comment