Starting about three weeks before anticipated harvest, fruit of each selection is tested weekly for starch conversion.

Washington Tree Fruit Research commission

The Washington State University apple breeding program is focused on developing novel apple varieties that will meet or exceed the quality of currently grown commercial varieties, both off the tree and after storage.

After initial seedling selection and evaluation (Phase 1) and small-scale on-farm trials (Phase 2), promising selections go into the Phase 3 intensive industry-evaluation phase, which will provide crucial horticultural performance data for each advanced selection of interest to the apple industry.

Phases 1 and 2 were described in an article in the July 2011 issue of Good Fruit Grower.

How does Phase 3 work?

The Washington Tree Fruit Research Commission, in collaboration with WSU, oversees four Phase 3 test sites with varying climates. All trees are on Malling 9, usually M.9 337 but some on Pajam 2. The trees are planted 10 by 3 feet apart in all sites and typically grown in a tall spindle format. A minimum of 50 trees per site is needed to provide adequate fruit volume for storage testing. A hundred trees will provide additional fruit for packing-line tests, industry sampling, and market testing.

Horticultural performance is observed every year during a selection’s five- or six-year stay in Phase 3 blocks. Fruit size and annual cropping are two of the most important traits evaluated. Other important observations include: incidence of bitter pit, responsiveness to chemical thinning, and susceptibility to sunburn and mildew. These traits, along with tree growth habits and fruit characteristics, are collated with storage and handling data. The report is combined with Phase-2 data collected by WSU.

As data are gathered, the breeding program’s Industry Advisory Council recommends whether to advance selections or discontinue their Phase 3 evaluation.

Maturity evaluation

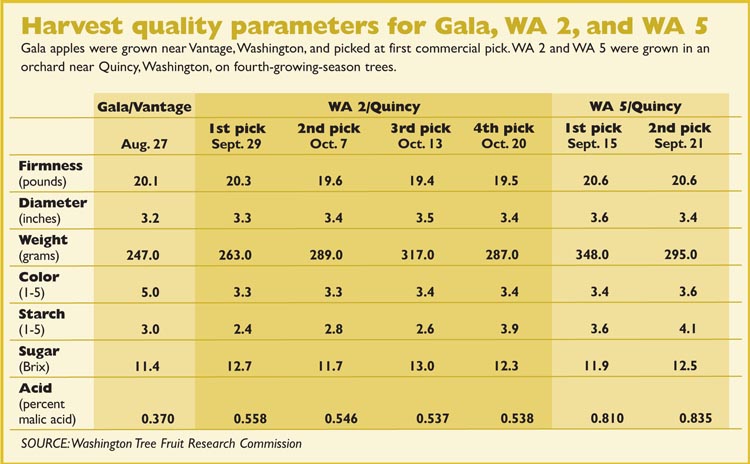

As harvest approaches, field monitoring of harvest maturity commences. Starting at about three weeks prior to anticipated harvest, four to six fruit are tested weekly for firmness, Brix, and starch conversion for each genotype. When harvest parameters for a selection reach optimum levels, as determined in Phase 2, the trees are segregated into four harvest dates and only 25 percent of the trees are picked at one time. All the fruit is stripped off some sample trees and placed in a packed box. The fruit is then sorted by color, photographed, and examined for defects such as cracking. A maturity evaluation is performed on each set of samples at the time of harvest (See “Harvest quality parameters for Gala, WA 2, and WA 5). Fruit is then transported to a research controlled-atmosphere storage facility at Stemilt Growers in Wenatchee and drenched to reduce decay.

It is then placed in regular-atmosphere cold storage for two months and evaluated again.

Storage trials

After the best target maturity is determined within the first few growing seasons, subsequent harvests are split into two picks unless the variety needs more in order to be color picked, as is the case with WA 2. Fruit is drenched to reduce decay, and half of each batch is treated with MCP (1-methylcyclopropene) within one week of harvest. The fruit is divided again, into two- and four-month research controlled-atmosphere storage (at 34°F) and four- and eight-month controlled-atmosphere storage (with 1% carbon dioxide and 2% oxygen) to determine storage performance under a variety of basic commercial storage scenarios. Following each storage time, fruit is pulled and held at room temperature for one week prior to evaluation. Basic fruit quality and maturity parameters, including the amount of greasiness and presence of storage disorders, are noted.

Packing-line trials

With increasing amounts of fruit available from Phase 3 sites, we were able to run several packing-line tests in the 2010–2011 storage season on a commercial packing line in Yakima. We evaluated the behavior of fruit when subjected to a standard waxing and packing scenario, with and without presizing. After each run, fruit was placed back into cold storage for two to three weeks, and final evaluations were performed after a one week at room temperature to mimic shipping and store display. Performance criteria include the appearance of the wax, number of punctures, and incidence of lenticel breakdown.

Leave A Comment