Apple growers across the country have been trying out a hand-freeing stem clipper developed by a Pennsylvania fruit producer.

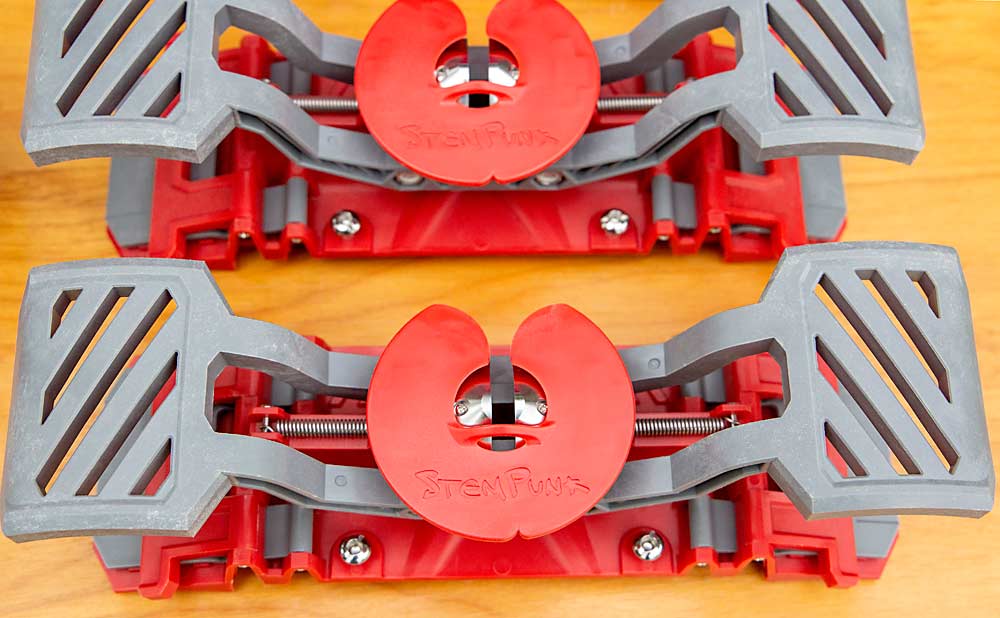

The StemPunk fastens to the straps of an apple bag, allowing the picker to use both hands for harvest. Pickers actuate the device by depressing a lever with their forearms while holding the fruit in place with one hand.

The product is for sale, but it’s early in the game, said inventor Leighton Rice, the quality assurance manager for Rice Fruit Co. of Gardners, Pennsylvania.

“It’s a good Gen-1 device that I think will add value and people will buy,” said Rice, a fifth-generation member of the family that owns Rice Fruit, the 2011 Good Fruit Growers of the Year.

Rice loaned out roughly 100 units to growers throughout Washington, Michigan, New York and Pennsylvania to test, for no charge. The only condition was to provide feedback.

And they did.

As with any new product, reviews have been mixed. Indeed, it allows workers to use both hands while they work, without having to hold hand clippers, growers said. However, some growers balked at the price tag — $125 each. Hand clippers run between $10 and $30. Others suggested mounting it somewhere besides the chest, adding an electronic actuator and adjusting the blades to clip deeper into the stem bowl.

But Rice is on the right track, said Dave Taber, an Okanogan, Washington, grower.

“The concept is excellent because stem clipping definitely slows our production now,” Taber said.

Taber asked one of his veteran workers to try it for several hours. The man had to lengthen the straps of his bag to make room for the StemPunk, about the size of a three-hole punch commonly seen in offices. That made his bag uncomfortable, restricting his movement. Also, in his worker’s experience, the device accidentally bumped the apples on the top of his bag each time he visited the bin.

But the picker used both hands instead of one, which makes the idea worth fine-tuning, Taber said. “We need something like this for sure.”

Juan Munguia, a technician in Washington State University’s Prosser extension laboratory, wishes he had a StemPunk years ago as a high school student picking apples with his father in nearby Mattawa. That’s how he earned money for school clothes.

“I hated it because … your hand cramps up and it gets stuck in that position because you’re doing it all day and you’re trying to do it as fast as you can,” he said.

Munguia demonstrated the StemPunk at two WSU field days in September, one in Spanish, one English.

History

Rice came up with the idea after watching companies backed by venture capital pitch expensive, complex solutions. The industry needs those, but many of the startups didn’t seem to understand farming, he said.

Meanwhile, stem clipping has become a greater expectation on growers and shippers. Washington State University recommends growers clip the stems of its newest apple, the WA 38, marketed as Cosmic Crisp. From his post as the quality assurance manager on the Rice Fruit packing line, Rice said he notices when the task is not done or not done well. Growers often just write off the puncture culls as the cost of doing business.

In 2016, using some inheritance money, Rice began designing a stem clipper with the help of a Maryland-based product developer named Chris Toner. They started with battery-powered, wrist-mounted units reminiscent of “Edward Scissorhands.”

But after two prototypes and a lot of investment, he decided it didn’t reach deep enough into the bowl. What’s more, its circuit board, small parts and need for charging undercut his ethos of simplicity. “It was too ambitious,” he said.

So, Rice and Toner switched to the mechanical version under trial now, which has been named a Top 10 semifinalist for the 2022 American Farm Bureau Ag Innovation Challenge. Winners will be announced in January.

Still, Rice admits the StemPunk, now on its sixth prototype, has a long way to go before he can claim success. But he’s having fun trying.

“I’m not afraid of losing money,” Rice said. “I’m just afraid of not taking chances and living a life that’s kind of boring.”

—by Ross Courtney

Leave A Comment