Weeds can be the bane of an organic grower, but Mike Young solved the problem by building a flamer, which he attached to the front of a four-wheeler. A liquid propane tank is at the back.

Every morning, after his first cup of coffee, Mike Young jumps on his old Suzuki four-wheeler and drives through his orchard, his long gray hair flying in the wind. His mission: to check his codling moth traps and look for signs of moth activity in the trees.

He knows his trees, and has no trouble spotting a wormy apple. But these days there aren’t many of them, thanks to the granulovirus he’s using. At age 60, Young is leading the minimalist lifestyle he feels he was destined for. At his seven-acre organic orchard at Parker, Washington, he drives a modest 25-horsepower tractor, builds his own farm equipment, and carries no cell phone.

“People up here are calling me a hippy,” he noted. “It’s okay. I qualify.” Young grew up in northern California, but back in the 1960s, he was a responsible young man who was kept too busy helping his father on home-building projects to even think about flower power.

After serving in the U.S. Navy, he went to California State University in Sacramento and earned degrees in biological science and chemistry. He was unsure what he wanted to do in life. “The current of life moved me forward, and I had an opportunity to use my skills in rocket science,” he recalled. But after an explosion of rocket fuel ripped out a wall of the aerospace lab where he worked, he decided to seek a safer career.

Pesticides

He got a job as a refrigeration engineer with Placerville Fruit Growers Association, and eventually became manager of the cooperative. He had to get a pesticide dealer’s license to provide pesticides to the growers, and remembers wondering why so many chemicals were needed to grow fruit. The job involved travel to the Pacific Northwest as a representative to the Winter Pear Control Committee, and he liked what he saw.

“The fruit folks were vibrant and enthusiastic and just going for it,”

he recalled. He wanted to be a part of it. In 1977, he took a job as manager at Peshastin Fruit Growers Association. He thought it a good omen to move from PFGA in California to PFGA in the state of Washington. Two years later, he went to work for the processor Tree Top, Inc., as southern field manager. He was responsible for all growers south of Interstate 90, which included Oregon, California, and Idaho as well as the southern half of Washington.

“I enjoyed being with the growers, no matter if I had to drive horrendous miles,” he said. When someone told him it didn’t take rocket science to grow apples, he began to think he might try it. Tree Top gave him the opportunity to take part in grower field days.

On hot afternoons in dry places like Mattawa, Washington, he’d pull out the ice chest and hand out Tree Top juice, but he was also listening, observing, and becoming more and more interested in being a grower himself. When he went through the Washington Agriculture and Forestry Education Foundation’s leadership program in 1986-88, he learned more about fruit growing from classmate Brooke Peterson, then a Washington State University Extension agent in Yakima.

Dressed in formal business attire, the two would drive to the seminars together and talk about the ideal orchard. By the time Young was seriously looking for an orchard, he had a list of criteria. It should have deep soil with no lead arsenate. It should have good air drainage, and it should be in a frost-free location.

The latter was important because he neither wanted to burn fossil fuel to heat the orchard nor spend sleepless nights during frost season. Finally, he found a 58-acre piece of land in Parker that fit the bill. He and neighboring orchardist Chuck Peters bought it in 1989 and split it between them.Young took a 30-acre piece with seven acres of Red and Golden Delicious apples on it.

“It was correct that I got this piece of land because I had within $500 to pay cash for it,” he recalled. The first thing he and Peters did was to push out all the Red Delicious trees and burn them. Young kept the three acres of Goldens because he figured he could sell the culls as peelers, which would return more than juice apples. He left his job at Tree Top and worked as an independent processed apple broker in Yakima while developing his orchard.

When he replanted, he recalled a comment he had heard at a field day: “We don’t need to grow air. The trees are too far apart.” He planted Fuji, Ginger Gold, and Gala on a five-wire mini-Tatura system, with 2,517 trees per acre, and nine feet between rows.

Having a lifelong fear of heights and ladders, he’s kept tree height to eight feet so that almost all the fruit can be picked from the ground. He’s since grafted over the Ginger Golds to Gala. He has a lone Red Delicious tree that he uses to set his degree-day models. Young says he’s less concerned about yields than about growing top grade fruit in the right size range that returns the best premium. “It’s not a huge number of bins, it’s what goes into the bin,” he explained.

Seven years ago, he switched to organic methods to avoid having conventional sprays drift onto an adjoining organic orchard. Though the main motivation was to avoid further disagreements with his neighbor, Young said he was approaching organic already and he sees it as the “new millennium” approach.

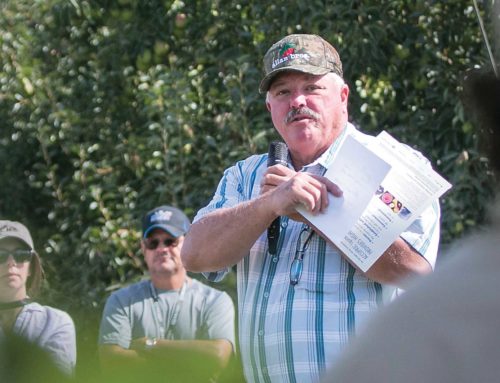

Weed flamer

People warned him that weed control would be the greatest challenge, but it didn’t take him long to figure that out. Being mechanically minded, he built a flamer that he attached to the front of a dedicated four-wheeler, with a tank of liquid propane towed behind.

The flamer shoots out super-hot flames about 30 inches long—similar to a Bunsen burner in a chemistry lab, he observed. He aims the flames around the tree trunks, and has found it best to operate his undertree sprinkler system at the same time to quell spot fires. The practice is exempt from burning bans because there’s no combustion of the weeds.

He’s also built his own sprayer small enough to fit through the narrow rows. It has a 1960s stainless steel tank and the nozzles are positioned so they are close to the tree and don’t blow the spray over the canopy. It’s enabled him to reduce his product rates because so little of the spray is lost. When he’s spraying, he attaches a mower to the tractor so he can mark the territory.

He likens spraying to painting the trees. When he needs to refill the sprayer, he can see where he’s mowed and knows exactly where to pick up again. However, he only mows alternate rows so that he doesn’t remove all the habitat for beneficials at the same time.

He has wild roses planted at the ends of tree rows. The strawberry leafroller, which infests wild rose, is an overwintering host for the leafroller parasite Colpoclypeus florus. He is planning to plant a bed of nectary plants alongside the orchard as a refuge for beneficial insects.

No oils

Young is in frequent contact with researchers at Washington State University and at the U.S. Department of Agriculture’s laboratory not far from his orchard. After learning from a WSU horticulturist that oil sprays clog the stomates of leaves and reduce the tree’s photosynthesis for a time, he stopped using oil sprays.

He reasoned that he needs optimum photosynthesis throughout the season to produce large, top quality fruit. Not using oils allows him to apply calcium sprays season long without fear of the combination affecting fruit finish. He doesn’t even apply delayed dormant oil sprays because he thinks they might smother overwintering beneficial insects.

He’s also skeptical about the benefits of mating disruption since seeing up to 30 percent fruit damage from codling moth in his orchard. He thinks moths might be adapting to it. He’s a great believer in the codling moth granulovirus. After using it for three years, he’s seeing minimal fruit damage. He continues to use mating disruption as an insurance policy, however.

A weather station in the orchard enables him to monitor real-time air and soil temperatures, wind speed and direction, soil moisture, relative humidity, and radiation at a computer in his office. He plugs the data into pest models to time his controls. But he also likes to be out in the orchard where he’s beginning to understand intuitively what’s going on.

“The trees are starting to talk to me now,” he said. “I’m starting to understand treeology and become more familiar with soil and leaf analysis.” Spiritual journey For Young, becoming a fruit grower has been something of a spiritual journey—and a humbling experience, he says. Each morning, after checking his trees and traps, Young goes up the hill overlooking his orchard to a rocky spot he calls Ponder Point.

There, he quietly meditates on his strategy for the day. Looking down over the entire orchard, he gains a different perspective and can spot the areas that need attention. “It’s just a good observation of what’s happening,” he said. “It helps me pinpoint what’s going on.”

Leave A Comment