Sprayer maintenance matters.

When Washington State University regional extension specialist Gwen Hoheisel talks about investing in equipment to save money on spraying, she is not talking about computer vision systems, smart technology or lidar. She means new nozzles, fans that blow the way they’re intended to and gauges you can actually read. Growers could save money on chemical bills just by upgrading their nozzles, she said at a field day in August near Prosser.

Current technology offers more precision in spraying than ever before. Smart Apply uses lidar sensors that detect canopy presence and density and then trigger pulse width modulation solenoid valves to adjust nozzle output based on the size and presence of vegetation. Many commercially available rate controllers adjust pressure to regulate spray rates as tractors speed up and slow down.

But even those tools miss their targets if old-school hardware fails.

Hoheisel regularly discusses the need for maintenance checks at field days and gives tips for making adjustments. Here are a few examples of her simple but critical lessons.

Gauges

Make sure you can read your gauges, Hoheisel said. She likes to show off one that is cloudy and obscured. She found it on a farmer’s working spray tank one year.

Watch the needle, she added. If it does not return to zero when the sprayer is off, the pressure gauge is bad. If it settles at 5 PSI when not in use, don’t just try to do some mental math when you turn it on. Pressure measurement is not always linear.

There are ways to test a gauge with an air compressor and a known working gauge, but it might be easiest to just replace it, she said. Even some manufacturers say they are reliable for only one year.

“It is a simple thing to decide to replace your pressure gauge annually; $20 replacement cost, you know the part is working,” she said.

Nozzles

Nozzles can also be replaced relatively inexpensively every year, Hoheisel said.

But use ceramic nozzles, especially disc-core nozzles, she said.

The tree fruit and wine grape industries use a lot of oil, sulfur and other corrosive materials, she said. Brass nozzles have about a 1 or 2 resistance ratio, a measurement of how quickly material wears down. Stainless steel improves that by about fivefold, ceramic by about a hundredfold.

To clean nozzles, don’t use sharp tools, like coat hangers or paper clips. They cause damage and mess up the spray pattern of the nozzle. Use a toothbrush instead.

“Everybody goes to the dentist, and you get a free toothbrush,” she said. “And if it’s good enough for your teeth, you can use it for your nozzles.”

Cans of compressed air work, too, she said.

Airflow

Getting air volume and direction correct could be one of your biggest spray coverage improvements, Hoheisel said. You only want to blow droplets into the canopy within one row.

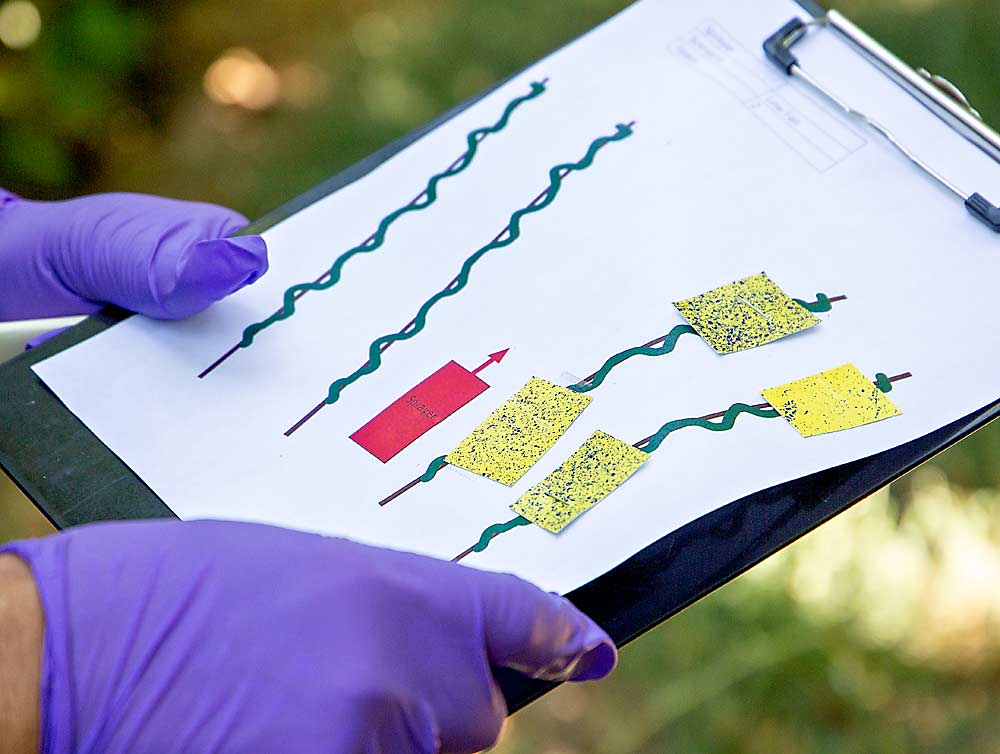

So, before spraying a chemical, test airflow and direction of the sprayer array valves.

The spinning motion of axial fans pushes air up on one side of the sprayer and pulls it down on the other. Some sprayers have air straighteners to correct for this. Remember, where air goes, droplets go.

Tie flagging tape to each valve, turn on the fan and see if that ribbon billows toward your canopy. If not, turn off that nozzle and recalculate the output per nozzle so that you can maintain the same rate per acre, she said. By not drifting into the air, you will increase coverage in the canopy — where it matters.

Also, tie flagging tape to the back side of canopies one, two or more rows away from the sprayer to test how much air is blowing through. If your air volume is set too high, the ribbons will blow straight out away from the canopy. That means you are going to miss coverage on your target row. To correct that, decrease fan size, lower the fan gear box if you have one, or use the “gear up, throttle down” method.

Rate control

Rate controllers need to be tested. They rely on a sensor, GPS or wheel to measure speed and adjust spray rate by changing pressure as speed changes. These help on hilly terrain, but changes such as replacing underinflated tires can throw off speed measurements and therefore application rates. Meanwhile, tractor speedometers are notoriously inaccurate.

Hoheisel suggested using an exercise app — she likes MapMyRide, a skiing and biking tracker — to make sure speed reported on the rate controller screen matches that of the app. If not, the computer or sensors are not calibrated correctly, and you should call the dealer to help you make an adjustment.

—by Ross Courtney

Leave A Comment