Data, data, everywhere, so much it’s hard to think.

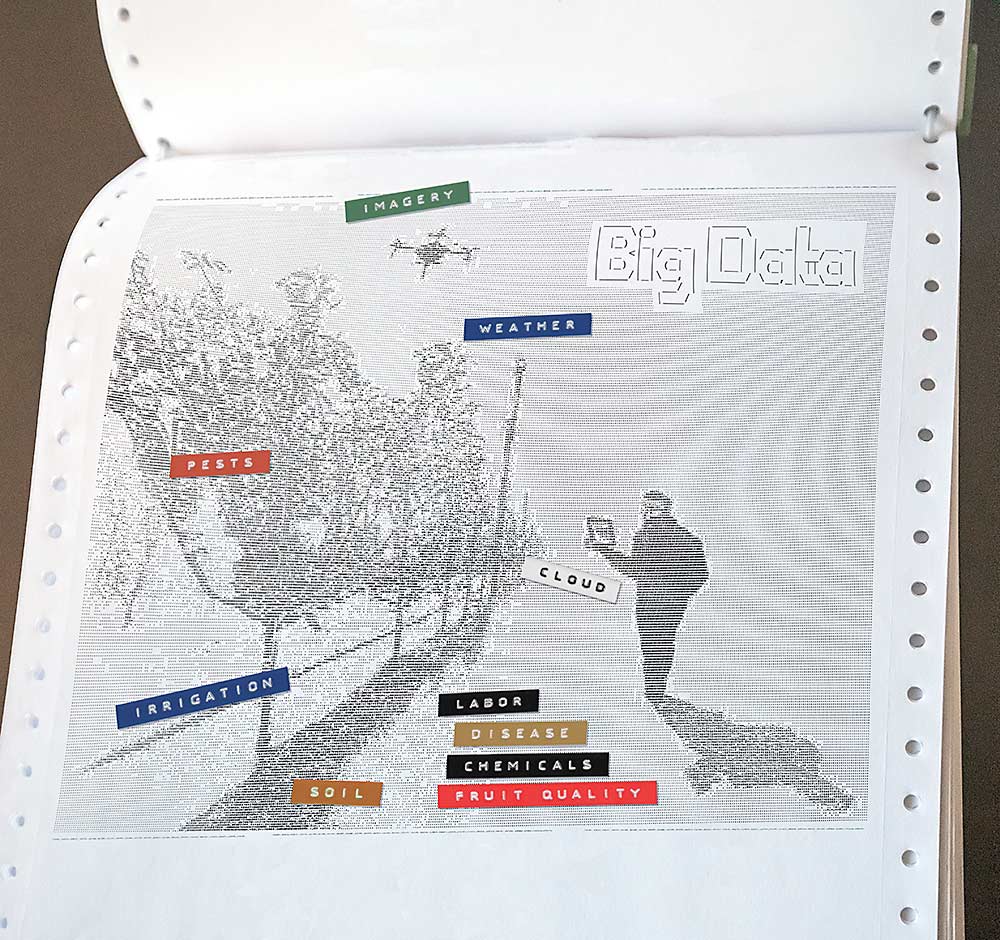

As drones, sensors, apps and other technologies proliferate, it can be hard to find time to make sense of it all.

“Everyone talks about big data in agriculture. It’s a good buzz word,” said Kim Bui, who heads up AgroFresh’s new digital platform for data analytics and infrastructure, FreshCloud. “But there’s way too much data and no one is making any insights.”

Now, startup companies and long-standing industry service providers are promising solutions for this data paralysis, as it’s often called, with integration strategies that bring data-driven insights to the forefront for decision-makers. The Good Fruit Grower talked with two such companies, each tackling opposite ends of the fruit supply chain: AgroFresh and innov8.ag, a Walla Walla, Washington-based ag tech startup.

“For us it’s bringing together real-world sensor data and, critically, nonsensor data such as labor and chemical and water and soil data, harvest data and imagery data to bring growers insights that are of value to their operations,” said Steve Mantle, who founded innov8.ag after a career with Microsoft.

Both Mantle and Bui said the big data revolution for the tree fruit industry needs to be a team sport: Tech and software companies with different areas of expertise must combine forces so that different layers of data can be coordinated for greater insight. They envision a future with platforms built on partnerships that could draw data from a dozen or so different weather, irrigation, imaging and labor tracking apps an orchard manager might have on a phone into one centralized command center or coordination that pulls orchard climate data into warehouse systems when it’s needed to make storage decisions.

“If I’m a grower and I can prescribe how I grow or handle my fruit to obtain the best outcome, I want to know that,” Bui said. “Right now, that data exists in multiple silos and, unfortunately, it’s really hard to tie together.”

Orchard integration

Reducing that potential for paralysis is also one of the primary goals of the Smart Orchard Project — a collaboration between the Washington Tree Fruit Research Commission, Washington State University, innov8.ag and Chiawana Orchards.

Members of the Smart Orchard team shared insights from the first year of the project and plans for moving forward at the Washington State Tree Fruit Association’s annual meeting in December.

“It was a full success,” said Ines Hanrahan, director of the research commission. “It enabled us to change the conversation regarding sensors and how to integrate them.”

Chiawana Orchards field operations manager Shawn Tweedy said the appeal of partnering with the project was the hope that coordinating data from moisture, nutrition, imagery and other sources would yield more actionable insights.

“One of the things we have struggled with in our organization is that the vendors have to produce something that is actionable for us immediately, not just a bunch of data for us to crunch,” he said.

In the first season, innov8.ag was able to bring data from many of the different participating sensor companies into one dashboard, so more information was available in one place.

But the tech challenge was actually the easy part, Mantle said. Linking multiple streams of data together into the actionable insights that growers such as Tweedy want requires a lot of research to understand how best to really use the data available from sensors, drones and apps.

“Where the complexity really gets into it is discovering and defining the key performance indicators,” Mantle said in an interview with the Good Fruit Grower. “We’re working through how to display the interrelation of (sensor and imagery data) in a simple way for growers, who are not data scientists, to understand at a glance.”

Take irrigation decisions, for example. That’s an area Mantle sees his data-integration efforts already offering benefits. Users can bring soil moisture sensor data, irrigation flow data and weather data from different vendors into one platform to both track and plan.

Eventually, similar symbiosis might be found aligning the imaging data counting the crop load and the labor tracking data calculating harvest wages, but it’s a harder puzzle to put together at this point.

A quality cloud

Bui joined AgroFresh in 2019 after 25 years in the semiconductor industry, bringing his data management insight to the new FreshCloud effort because the company saw an opportunity.

“The industry really lacks visibility in the supply chain,” he said. “It’s really complex, but we thought: ‘Can we harness our heritage in terms of our knowledge of how fruit is grown and stored and turn that into actual insights to help our customers deliver a great piece of fruit from their farm to the consumer?’”

Fruit quality in the postharvest supply chain starts with optimized harvest timing, so one of the first pieces of the growing FreshCloud platform is a tool to digitize starch tests, called HarvestView.

It’s a “glorified photo-sharing app,” Bui said. But by snapping pictures of the iodine-dipped fruit, the starch clearing data is synced with GPS data, date and time in the system. Then, the images go into a machine learning model that can measure maturity with more consistency and precision than people can. Size, color and pressure information can also be added.

With that information in the cloud, they began to figure out where else in the supply chain that fruit maturity information could be used to make better decisions and how to automate the collection of quality information that follows harvest in receiving, storage and packing, Bui said. They aim to put the right information in the right place at the right time, so that warehouse managers or sales desks can have the quality information they need to make the best decisions for each piece of fruit.

That means weaving FreshCloud data into many of the existing data systems operating at large fruit companies, Bui said, not trying to replace anything.

“Customers are already drowning in so many systems,” he said. “We don’t want to change their process. We want to help optimize it.”

Late in 2020, a few key customers signed on to do just that, including Montague, a large Australian fruit grower.

Other tools are in the FreshCloud pipeline, but Bui said AgroFresh also wants to partner with other sensor and data companies to incorporate other data streams to track fruit quality metrics from tree to tray pack.

“What’s our strength? It’s how fruit is grown and handled. We’re not building bin tracking systems or irrigation sensors,” Bui said. “At the end of the day, it’s all about integration.” •

—by Kate Prengaman

Leave A Comment