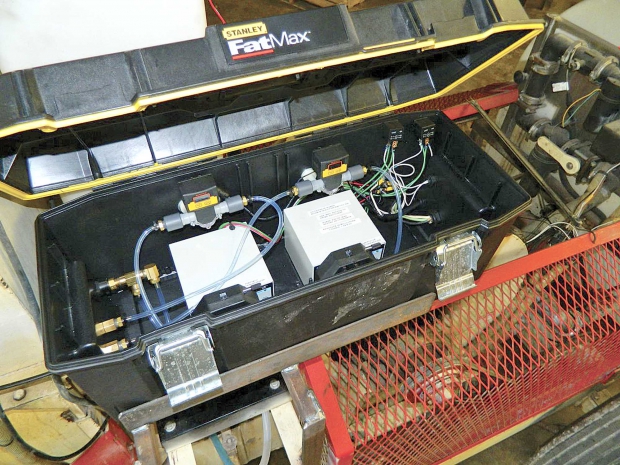

Mark Ledebuhr’s goal is to devise a low-cost system for injecting pesticide into the spray stream only at hot spots where pest pressure is highest. (Courtesy Mark Ledebuhr)

Direct injection sprayers are becoming more common, especially in the row crop world, but they’re expensive and most fruit growers still don’t use them. Is there a way to obtain their advantages while using other sprayers?

The answer appears to be yes. By the end of this year, fruit growers may be able to modify their sprayers with a kit costing around $4,000 that will allow their conventional sprayers to have the direct injection feature.

At least, that’s the goal of a project in Michigan. Here’s the story.

Wild hosts

Dr. Rufus Isaacs, a Michigan State University entomologist, has been working for some time to reduce damage from grape berry moth by destroying the berries they infest.

Grape berry moth, a pest that reduces yields, is a much greater problem in the vineyard perimeters, invading from wild hosts outside the vineyard and moving in only about 100 feet.

“Dr. Isaacs and his team have shown that you don’t have to spray the whole vineyard to get good control of grape berry moth,” said Mark Ledebuhr, who provides consulting services for spray applications. “But 100 feet is too deep to spray from the outside, using just a perimeter spray. You need to be close enough to force spray into the clusters to control berry moth.”

One simple solution would be to run your sprayer up and down the rows, turning it on near the end of the row and off the rest of the time. But that would be a waste of time and fuel. Since growers are often treating for grape berry moth while they also apply fungicides throughout the vineyard for disease control, the ideal solution would be turn the insecticide on and off, injecting it into the spray stream only when it is needed.

Grape berry moth can cause significant yield loss directly, as well as by opening clusters to invasion by diseases. (Courtesy Rufus Isaacs)

Hardware guy

“I’m a hardware guy,” Ledebuhr said, explaining how he got involved in the project with Isaacs. Ledebuhr runs a small company in Lansing, Michigan, called Application Insight, and for a young man, he has a long record in the spray industry.

His father is Dick Ledebuhr, a now-retired Michigan State University agricultural engineer who, along with colleague Dr. Gary VanEe, developed the Proptec and Curtec low-volume rotary atomizer sprayer technologies in the late 1980s and early 1990s. The Ledebuhrs cofounded Ledebuhr Industries 18 years ago to manufacture and sell the Proptec spray technology.

Mark moved on from Ledebuhr Industries three years ago to devote more attention to the science of spray evaluation and sprayer design, the focus of his current company.

The mission Isaacs gave him was to develop a design and a parts list that would allow growers to buy off-the-shelf components and modify their sprayers at a cost that would make this process economically feasible to as many growers as possible, ideally less than $4,000.

With funding from National Grape Cooperative, Project GREEEN, and the U.S. Department of Agriculture, this project is under way with a few years of vineyard testing still to go.

Ledebuhr spent 2013 testing various ideas, and hopes to have the project done by the end of 2014. He talked about it during the Great Lakes Fruit, Vegetable, and Farm Market Expo in Grand Rapids, Michigan, in December.

One challenge, Ledebuhr said, is to inject a small amount of undiluted insecticide—for example, four ounces of Belt insecticide per acre—into a dilute fungicide spray stream.

Another is overcoming the problem of latency—how far will the sprayer move down the row during the time the insecticide is moving from the pump to the sprayer nozzles.

Ledebuhr built a system for juice grape grower Bryan Cronenwett of Lawton, Michigan, and they worked with MSU research technician Keith Mason to run the trials last year. The team expects to have a more complete evaluation of this approach and a set of plans ready by year end so other grape growers can build their own.

The system may prove to be useful to other fruit growers. Grape berry moth is not the only insect that is a bigger pest on the margins than in the interior. Brown marmorated stinkbug is another.

Then there are “hot spots,” places in vineyards and orchards where there are patches of weeds or outbreaks of mites. Ledebuhr thinks this system could be flexible enough to find many applications beyond grape berry moth management. •

Leave A Comment