Paul Heinemann was sitting in a conference room a few years ago, listening to a presentation about commercial heaters and frost protection in orchards, when he had an idea: A drone flying through an orchard in spring, reading temperatures with a thermal sensor. When the drone found buds or blossoms in danger of frost damage, it directed a ground-based robot to the trouble spot, where an attached heater could warm it up.

Heinemann, a Penn State University professor of agricultural and biological engineering with experience in frost protection research, decided it was an idea worth pursuing. He teamed up with other Penn State researchers to write a grant proposal. They received $843,000 in funding from the National Science Foundation’s Cyber-Physical Systems program in 2019. With the project now in its final year, the team plans to test the concept in a research orchard this spring. They don’t expect to have a finished product for growers by the end of the project, but they do expect to have a much better understanding of how the technologies they’re studying can be applied in an orchard setting, he said.

When it comes to frost protection, most Pennsylvania fruit growers are gamblers. A few of them use wind machines or portable heaters, but for the most part they take their chances. Proper site selection is the main strategy in the state’s hilly fruit-growing regions, Heinemann said.

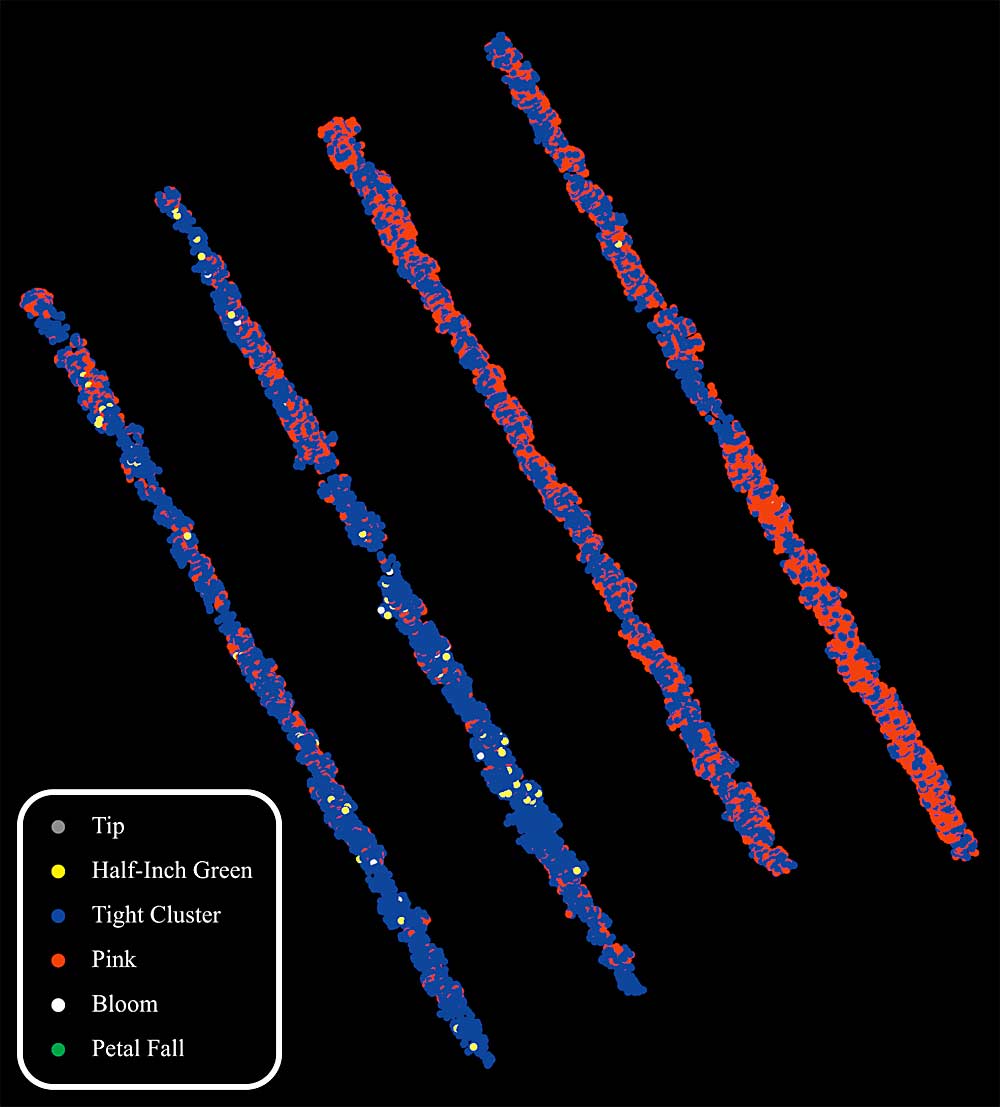

The Penn State team has worked out some of the precision frost protection concept’s technological components, but they’re still working on others. They can fly a drone, track temperature and bloom stage, make orchard maps based on sensor data, and move a heater via autonomous ground vehicle — but they haven’t yet figured out how to make the drone communicate instantaneously with the ground vehicle, said Heinemann, the current project leader.

“The heat maps are not really available in real time yet,” Heinemann said. “This spring, we hope to come up with simulated heating maps that tell the vehicles where to go. Maybe by fall we can transmit them in real time. It’s doable, but we just haven’t gotten there yet.”

Communication between vehicles could have more applications than frost protection, which is only needed for relatively short periods of time, he said.

Spring temperatures and blossom stages are constantly changing, so creating heat deficit maps based on those fluctuations was difficult. But the team developed a model that could do it, said Dana Choi.

Choi, a former Penn State professor, was the frost protection project’s leader until she joined the University of Florida in January. She’s still involved in the research, however.

Another challenge the team is still trying to master is knowing exactly how much heat is needed in an at-risk spot. How long should the heater sit there before moving? How widely will the generated heat spread, and how long will the heat linger? To answer these questions, they built a computational model, scaled to different heater sizes, that they’ve tested in simulations, Heinemann said.

After years of technology development and simulations, the team plans to bring all of the project’s different components together in its first field trials this spring.

“We’re pushing the limitations of this technology, finding out what is currently feasible,” Heinemann said.

The ground robot, at this point, is an electric Cub Cadet mower that a Penn State graduate student modified to maneuver autonomously.

“It could do autonomous mowing as well, but it won’t be mowing when doing frost protection work,” Heinemann said with a laugh.

The 150,000-Btu propane-powered heater attached to the Cub Cadet is smaller than the typical heaters placed in orchards, which are closer to 1 million Btu. Drone flight times are another potential limitation. To keep sensors in the air for longer periods, you’d probably need more than one drone, so one is always in the air while the other’s battery is being charged, Heinemann said.

The drone-to-robot method could provide effective frost protection in the future and eliminate the need for manual scouting of buds and blossoms. But the equipment, especially the thermal camera placed on the drone, is expensive. It might be better for interested growers to wait until the price comes down, Choi said.

—by Matt Milkovich

Leave A Comment