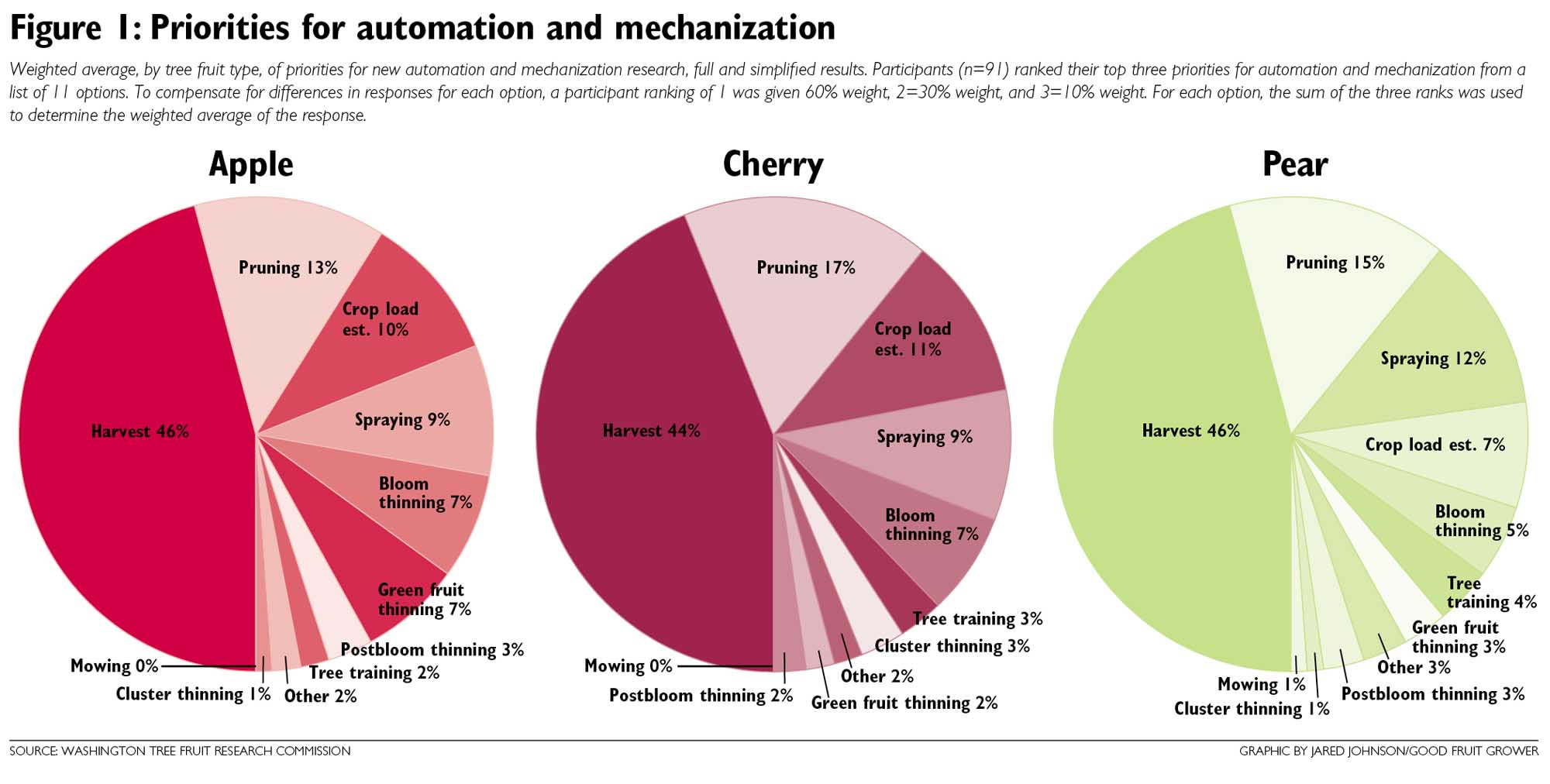

Figure 1: Priorities for automation and mechanization. Weighted average, by tree fruit type, of priorities for new automation and mechanization research, full and simplified results. Participants (n=91) ranked their top three priorities for automation and mechanization from a list of 11 options. To compensate for differences in responses for each option, a participant ranking of 1 was given 60% weight, 2=30% weight, and 3=10% weight. For each option, the sum of the three ranks was used to determine the weighted average of the response. (Source: Washington Tree Fruit Research Commission. Graphic by Jared Johnson/Good Fruit Grower)

Understanding grower-driven tree fruit industry research priorities is critical to identifying and funding research projects that will benefit a grower’s bottom line. Existing apple, cherry and pear production research priorities are used to determine funding decisions during the Washington Tree Fruit Research Commission (WTFRC) annual crop-specific research reviews.

However, specific, publicly available research priorities have not been developed to guide the Technology Committee, where most of the mechanization/automation projects are funded. When the Technology Committee was originally established in 2008, there was concern that industry experience with orchard automation was limited, and that limited experience might result in priorities that were not sufficiently futuristic or comprehensive.

In 2018, after over 10 years of evaluating and funding technology projects focused on automation and mechanization, we believe the Washington tree fruit grower community has a better feel for the types of tasks that would most benefit from automation. And, further, that understanding would be of value in attracting and guiding engineers and horticulturists with an interest in working in Pacific Northwest tree fruit production systems.

To gain an understanding of growers’ priority orchard tasks for automation/mechanization, we conducted a survey of participants during a session at the 2017 Washington State Tree Fruit Association annual meeting in Kennewick, Washington. Survey participants were asked to rank the top three tasks in orchard management that they believed would most benefit from automation and mechanization engineering solutions.

Ninety-one attendees of the automation/mechanization session returned the survey form, which was developed with the help of Washington State University’s David Granatstein, including 57 growers, nine field representatives and one vendor.

Twelve respondents were apple growers, 21 were apple and cherry/stone fruit growers, six were apple and pear growers, 38 grew apple, cherry/stone fruit and pear, and 14 did not identify a specific crop. Some attendees selected multiple categories, and six were both growers/field representatives, one was a grower/field representative/other and one was a grower/other. Sixteen selected other or did not identify their role in the industry.

The results of the survey are presented in Figure 1. Across crop types, harvest automation technologies were ranked highest among respondents for new research needs. Pruning, spraying and crop load estimation followed in order of importance, although crop load estimation was apparently slightly less important to the pear growers completing the survey.

Taken together, bloom thinning, cluster thinning, post bloom thinning and green fruit thinning accounted for 18 percent of selections in apple, 13 percent in cherry, and 12 percent in pear. In the thinning category, blossom thinning was rated as most important across all crops. Mowing and tree training consistently ranked low.

However, it is likely that when considering tree training, the respondents may not have been considering that tree training could be used to describe the process of orchard architecture modification to allow integration with automated harvesting equipment. Perhaps it was assumed that this type of activity would be covered in the desire for pruning automation. Automated flower counts and use of drones for application of these technologies were identified by survey participants as possible future research areas.

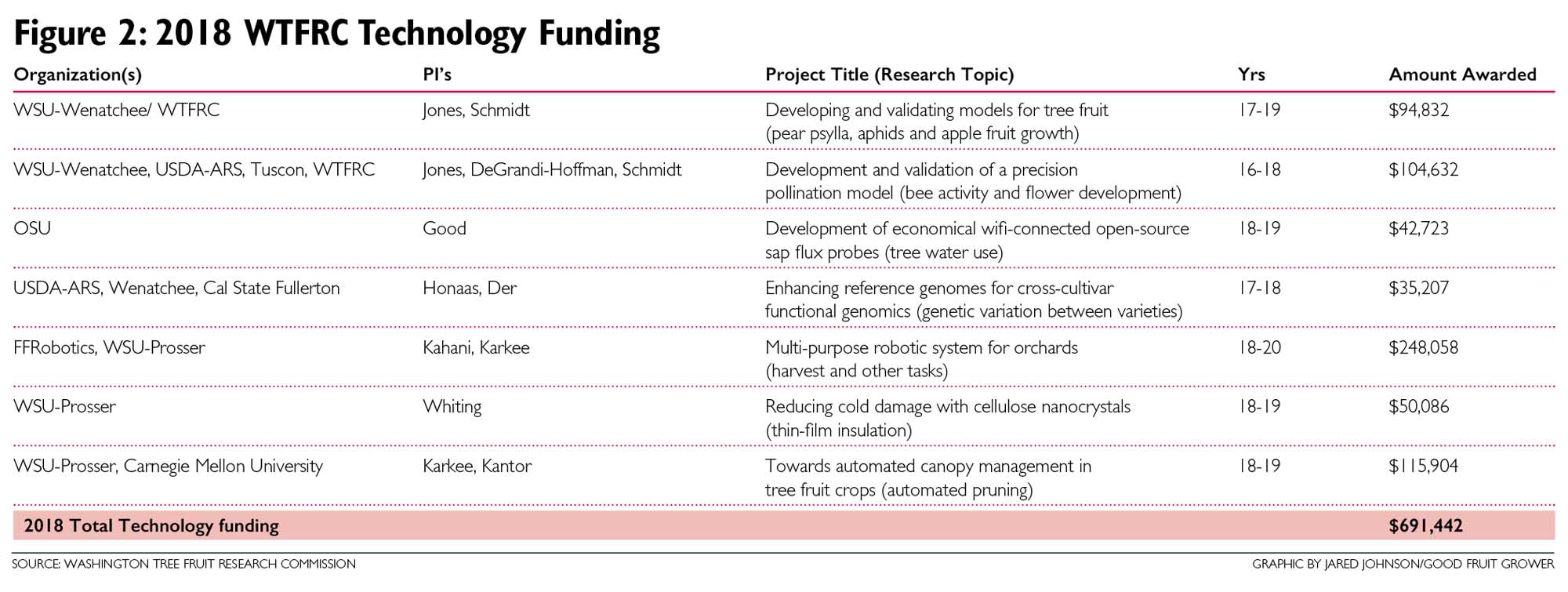

Figure 2: 2018 WTFRC Technology Funding.

(Source: Washington Tree Fruit Research Commission. Graphic by Jared Johnson/Good Fruit Grower)

To provide a snapshot of how closely current WTFRC Technology funding is currently tracking the priorities of the survey respondents, Figure 2 lists projects funded for the 2018 season.

In preparation for future funding cycles, the priorities identified at the 2017 WSTFA meeting will be further discussed with growers at various venues as well as with the WTFRC Technology Committee.

We want to ensure that we have captured the needs of the industry with a prioritization that can be usefully shared with the research community.

Also, the WTFRC and WSU Extension have jointly begun the development of a white paper to more fully flesh out future directions for orchard automation and mechanization research.

If the readers of Good Fruit Grower have additional ideas that could be included in future research planning, please contact one of the authors. •

—by Mike Willett, Karen Lewis and Rob Curtiss

Mike Willett (willett@treefruitresearch.com) is the manager of the Washington Tree Fruit Research Commission. Karen Lewis (kmlewis@wsu.edu) is with Washington State University Extension and is WSU’s tree fruit team leader. Rob Curtiss (rob@treefruitresearch.com) is the special projects coordinator for the Washington Tree Fruit Research Commission.

Leave A Comment