Scouting during harvest. Testing. Pulling trees and losing production. Spraying for leafhoppers after harvest.

Mitigating and controlling for X disease costs time and a lot of money, but a new economic analysis measures how not responding could cost growers even more.

“The mitigation practices have a tremendous payoff,” said Welcome Sauer, a retired tree fruit industry analyst now working with Washington State University on an economic model for X disease mitigation. X disease can be devastating for growers, but he hopes the model will show profitable paths forward.

His model also shows that by investing in steps to protect a profitable orchard — removing infected trees, spraying for leafhoppers and doing weed control — “you can get close to baseline profitability, even though the mitigation practices are costly,” Sauer said.

The approach helps researchers better understand the economic realities growers face when it comes to disease response, said Tobin Northfield, a WSU entomologist who has been working with Sauer on the project.

Eventually, WSU hopes to release Sauer’s model to growers as a workbook so they can adjust the base numbers for orchard operational costs, cherry prices or infection rates, for example, to run calculations that best reflect their own farms. It would be similar to the enterprise budget spreadsheets WSU economist Karina Gallardo builds for the industry, Sauer said, adding that those budgets provided the baseline for his work.

The model covers seven treatment scenarios and dozens of input variables across time horizons up to 60 years. Sauer called it “the most sophisticated model” of his career, encompassing some 340,000 calculations.

While it will take some time for the model to be built into a user-friendly tool, Sauer and Northfield walked Good Fruit Grower through the takeaway messages from a few basic infection scenarios.

The ideal scenario: Never get the disease in the first place.

“If I was planting a cherry orchard today, my first action would be to defend my boundaries with barrier netting,” Sauer said. That may seem like an extreme investment, but in areas with disease pressure, the one-time upfront cost for prevention will pay off over the lifespan of a healthy orchard. “I’m going to trap constantly, and I want to be a very hostile host to those vectors. I don’t want them to live in my weeds.”

But infections happen. At planting, it’s an economic disaster, Sauer said. But a more typical case is continuous vector pressure.

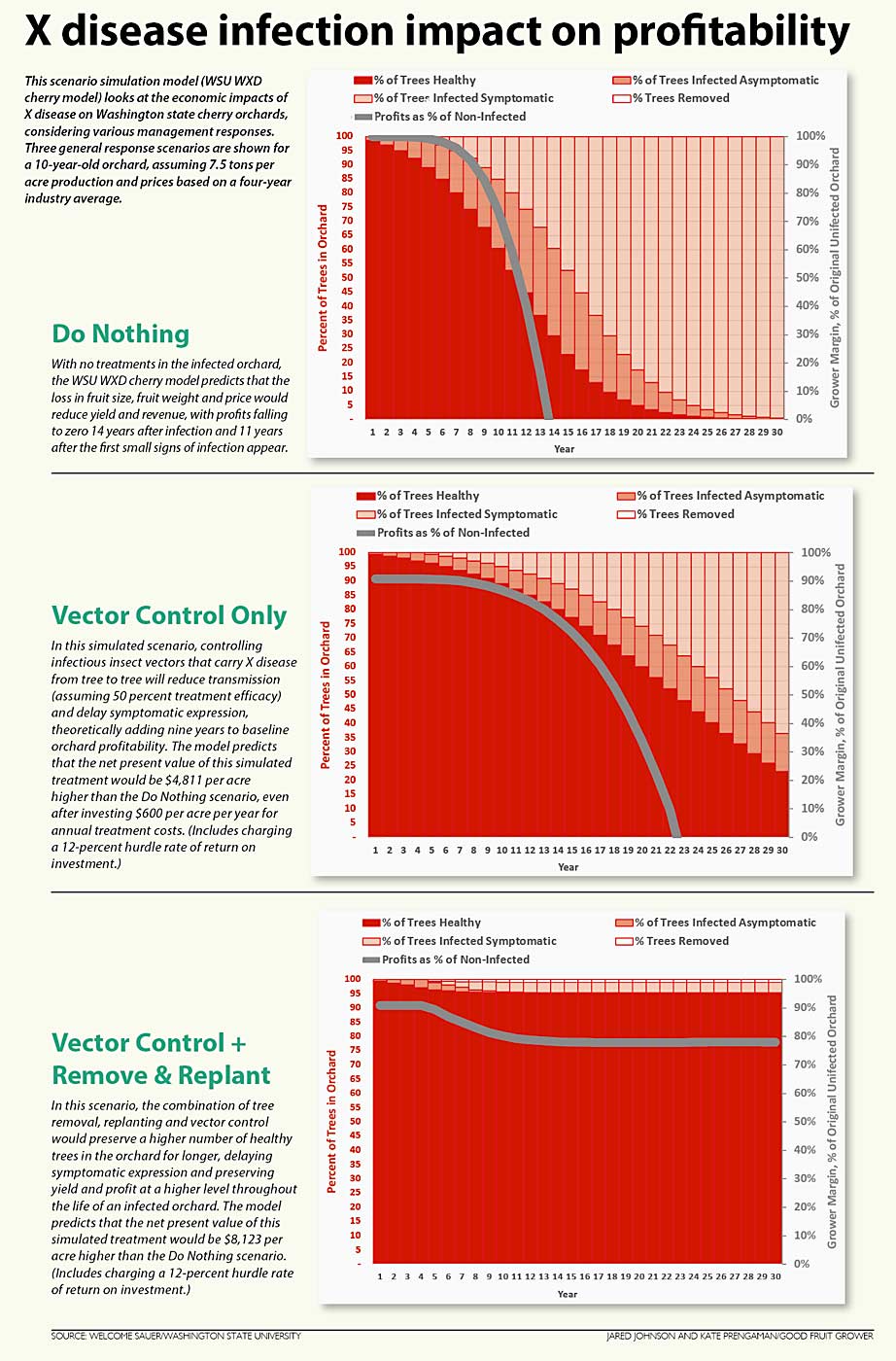

For a grower harvesting in week four of the market and who has disease spread at 1 percent per year, investing $600 per acre in vector control adds about nine years to orchard profitability, Sauer said, compared to the do-nothing scenario, which shows profitability tanking in about 12 years.

If that grower also aggressively removes infected trees and replants, reducing sources of disease and maintaining a higher number of healthy trees in the block, the block should stabilize and be profitable, though the margins would be lower than a block that was never infected.

Of course, the value of those interventions depends on the lifespan growers expect from the block and the value of the fruit it produces, Sauer said. The model can reflect that, so growers can consider the costs and benefits relative to their own operations.

“The bottom line is if we are going to be profitable cherry growers, it requires more intensive farming than we’ve had in the past,” Sauer said.

The model also accounts for the fact that the disease spreads invisibly for several years before growers realize they have a problem.

“Because the disease has this latency period, there are these years of lost revenue while we are mitigating. The financial losses are large, even though we are removing trees and catching up over time,” Sauer said.

And the economic toll starts earlier than researchers were initially measuring. X disease eventually causes fruit to become small, pale, poor-tasting and utterly unmarketable. But in the early stages of disease, it starts to reduce fruit size.

“We were focused on the cherries that weren’t being picked,” Northfield said, “but you’ll lose a lot of money on that tree from lower-value fruit first.”

That should cause both a yield loss and compounding effect on size loss, lowering prices, Sauer said. Currently, the model estimates fruit from symptomatic trees would be smaller than 12-row size and the infected but asymptomatic trees would shift down a half-size smaller. As better data becomes available on the rate of that size loss, he can refine the model.

“It’s a simulation model to work within the ballpark of growers’ intuition, before we get more data,” he said.

Same goes for the data refining the impact of mitigation practices. The industry doesn’t yet have enough information, but the model aims to fill the gap with estimates, Sauer said.

“I think it’s going to help educate growers and researchers to understand the economics and the challenges,” said Garrett Bishop of G.S. Long Co., who has reviewed the model. “The key take-home for me was the number of infected trees at the beginning makes a big difference.”

—by Kate Prengaman

Leave A Comment