Washington State University researchers have identified materials and steps to improve long-term storage of organic apples.

Studies are ongoing, but trials from plant pathologist Achour Amiri and endowed chair for postharvest systems Carolina Torres have yielded a few bits of technical advice for growers and packers to maintain fruit quality and prevent disease during the long months of storage.

“Postharvest is a great challenge for organic fruit … but we need to store that fruit 12 months anyways,” Torres said at the Washington State Tree Fruit Association Annual Meeting in December in Kennewick.

Both work at the university’s Tree Fruit Research and Extension Center in Wenatchee. Their experiments were funded with more than $2 million in grants from the Washington Tree Fruit Research Commission and U.S. Department of Agriculture’s organic and sustainable programs. The funding also covered economic research into the costs of organic apple production.

Decays

Among Amiri’s conclusions: Multiple sprays of several organic products throughout the season generally do more to reduce postharvest rot than the standard practice of spraying only near harvest.

“We can say (that) with a level of certainty,” Amiri said at the annual meeting.

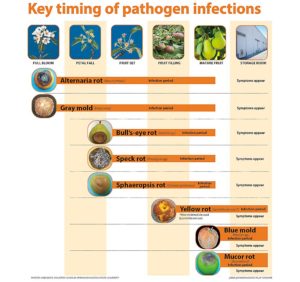

Organic materials show variable results year to year, especially biologicals, Amiri said. However, on average, rotating field applications between three or four high-performing sprays at different periods throughout the season, starting at petal fall, protected fruit for eight months in storage. In contrast, some sprays applied once in the weeks leading up to harvest only bought four or five months of safe storage.

This does not surprise Amiri. For years, he has told growers that rot prevention begins early in the season in the orchard, because that’s when fungal pathogens first start to attack. Rot is not just a warehouse problem.

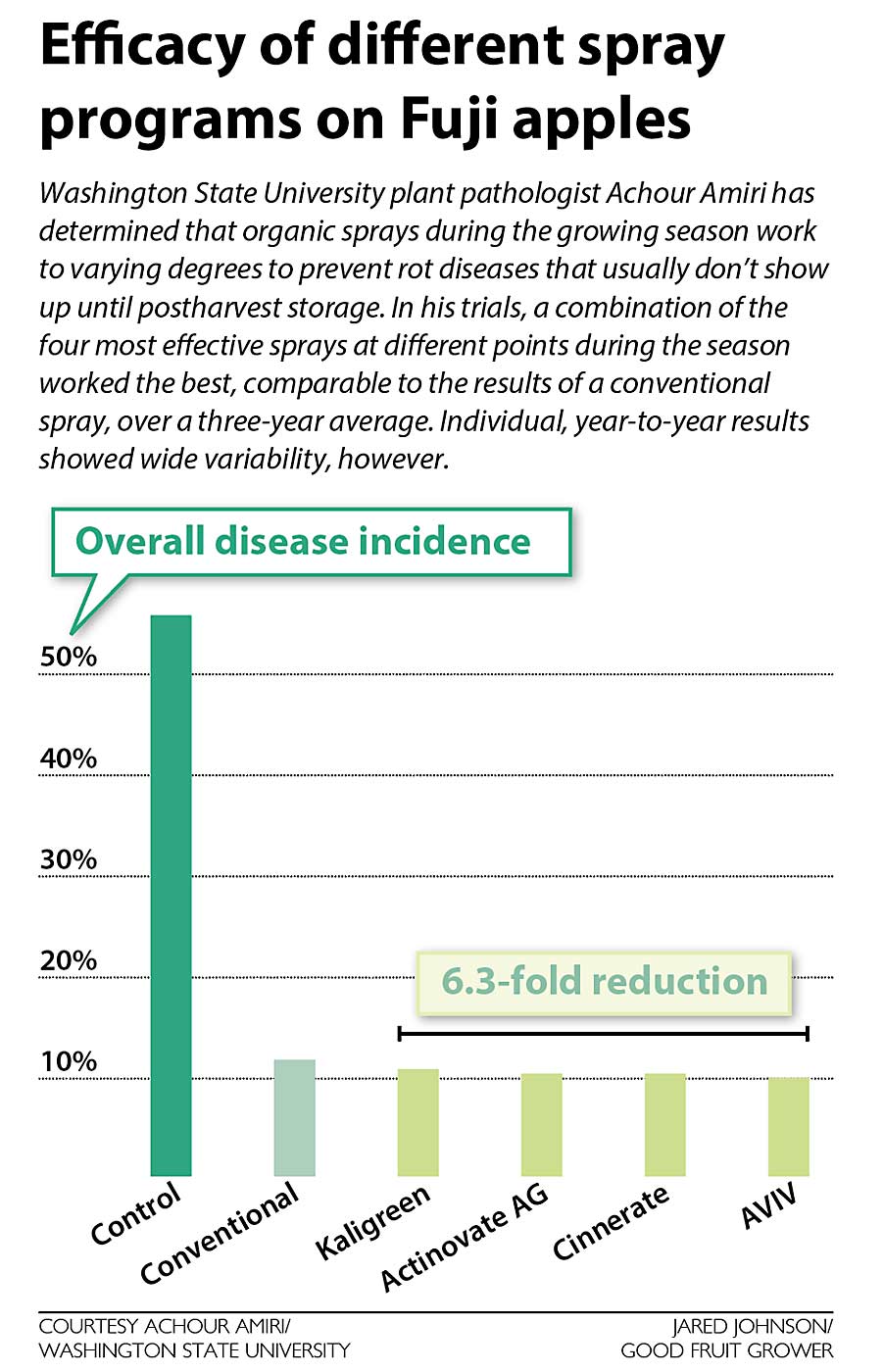

Though Amiri does not endorse certain products, his team tested 14 different organic materials — biologicals, plant extracts, salts and biofungicides — in the field. All of them beat a water control, but four seemed to perform best.

Again, year-to-year, the substances had a wide range of efficacy. But over three years, Kaligreen (potassium bicarbonate), Actinovate AG (Streptomyces lydicus), Cinnerate (cinnamon oil) and AVIV (Bacillus amyloliquefaciens) reduced rot incidence by greater than sixfold when applied once individually seven days before harvest. A conventional spray has similar results.

He called that good news.

The verdict is still out on storage regimes. For two years, ultralow oxygen and dynamic controlled atmosphere reduced incidence of gray mold, speck rot and bull’s-eye rot more than traditional controlled atmosphere and cold storage, but then gave opposite results for the 2023 crop. That research will continue, as well.

Dynamic controlled atmosphere allows warehouse managers to adjust oxygen levels based on an assessment of a sample of fruit.

So far, Amiri has used Fujis in his trials, but he will add more varieties once he gets more consistent results, he said.

Fruit quality

While Amiri focused on diseases, Torres studied how fruit quality holds up during storage.

Based on her trials so far, controlled atmosphere storage works at the following levels: For Honeycrisp, 1–3 percent oxygen and 0.5–0.7 percent carbon dioxide; for Fuji apples, 0.8 percent oxygen and 0.7 percent carbon dioxide.

She plans to continue postharvest studies through 2025 with more detailed trials about dynamic controlled atmosphere storage. So far, the research has just answered some baseline questions, she said in a follow-up interview with Good Fruit Grower.

She also wants to develop best practices for what happens to fruit after it is removed from storage and moved through the cold chain to store shelves.

Torres has been seeking ways to use measurable characteristics of organic apples — Brix, firmness, acidity and so on — to predict how long fruit will hold up in storage. For example, low malic acid means a lot of fruit won’t make it.

With conventional crops, those factors don’t matter as much because warehouses have 1-MCP and fungicides.

That kind of research needs a long time frame. Her first four years of results show a lot of variability caused by an intense heat wave in 2021, cool pollination weather in 2022 and then a massive crop in 2023. By the end of the USDA grants, she will have seven years of data from the same blocks.

Predictive metrics are not new, she said, but the industry’s primary maturity indicators need updating. In separate projects, geneticists with the USDA are looking for genetic markers to develop new maturity predictors, she said.

In the end, she hopes to have a better set of tools for production companies to use predictive metrics to make their storage decisions.

“That’s where all the magic is,” she said.

—by Ross Courtney

Leave A Comment