Rick Howitt, right, monitors a small computer that records data collected from a Huron Fruit Systems platform during apple thinning on July 1, 2016 at Wafler Farms in Wayne County, New York. (TJ Mullinax/Good Fruit Grower)

Wafler Farms wanted to do more than just mechanize tasks on the farm.

Paul Wafler also wanted to be able to monitor the progress and location of the farm’s own Huron Fruit Systems platform in the orchard, as well as track yields and worker performance.

He wants the orchards running like a production line; wherever there is a problem, he wants to be able to see it and correct it as quickly as possible.

A $3,000 add-on monitoring system, built to Wafler’s specifications by Agrinetix of Henrietta, New York, makes that possible.

“It’s not a surveillance system as much as it is a tool to improve worker performance and reduce culls and bruised apples,” said Rick Howitt, Agrinetix’ director of information systems.

For Wafler, it’s a system that allows him to both control and track costs. “At any given time, I know where my workers are, what they are doing. It is all about maintaining a flow,” he said.

How it works

Cameras mounted on the front and back of the platform and positioned to record activity on the entire platform shoot 20 seconds of video roughly every hour (the time intervals are configurable).

The recorded video is transmitted to USB storage, via power over Ethernet cables, which carry both data and electrical power.

The system’s brain is a Raspberry Pi microprocessor, which is about the size of a cigarette pack and costs about $35.

It has one gigabyte of memory, can save data via any size USB thumb drive and uses the Linux operating system. The whole system is housed in a weatherproof box.

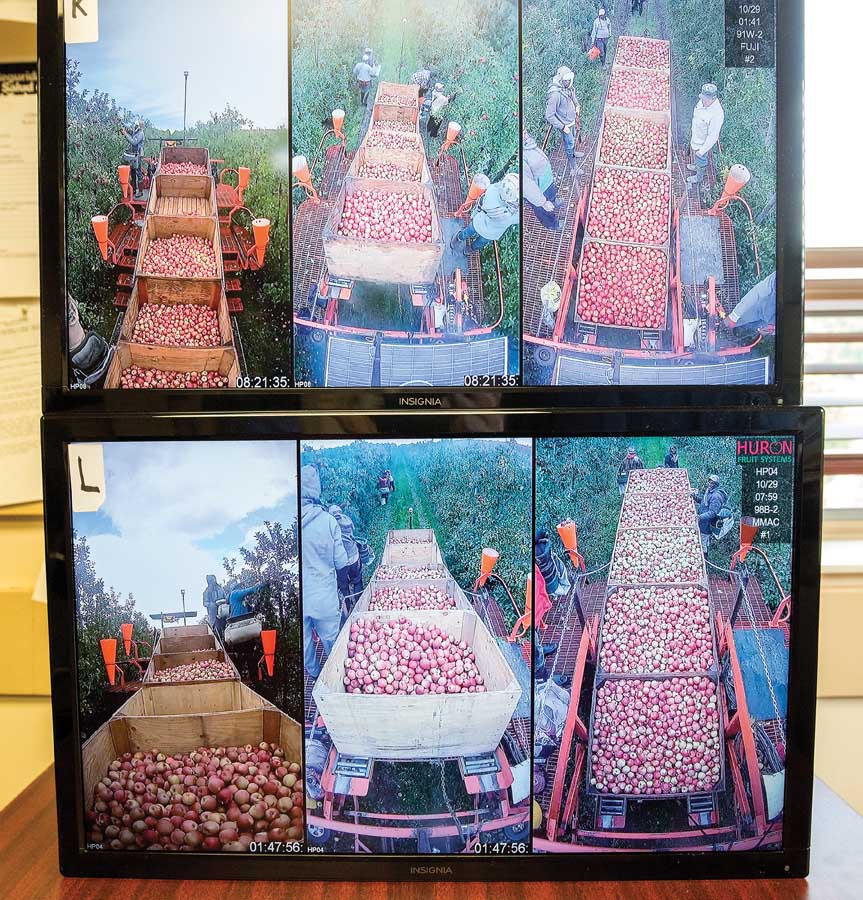

A small computer records crew use data on a Huron Fruit Systems platform during apple thinning. The computer displays some live data on the screens such as variety, location and distance. Recordings and data are both written on a USB stick, at right bottom. (TJ Mullinax/Good Fruit Grower)

Another Wafler modification uses one of the video cameras to take a picture of the bins at unload as a quality control tool.

“We added a switch that trips when the bins are full, taking one picture of all five before unloading as a check against quality,” Howitt said.

At the end of the day, supervisors deliver the video data on USB drives to the office, where a software program compiles those video snippets into a 6-minute video.

Wafler set up 10 kiosks, one per mobile platform, in the area where workers gather in the mornings and evenings to review the previous day’s videos.

Apple thinning crews look over Huron Fruit Systems video and thinning speed data before heading out to work the morning of July 1, 2016. (TJ Mullinax/Good Fruit Grower)

The video rendering software splits the kiosk television screens into three panels: The left panel shows the front platform view, the right panel shows the rear platform view and a third provides a list of the day’s unloads as well as photos of each unload.

Based on the videos, workers and supervisors determine ways in which individuals or crews might improve their efficiency.

In addition, the review also addresses overall pick quality, including the consistency of fruit color and quality.

Images of apple harvest captured on September 29, 2015 by wifi connected cameras on a Huron Fruit Systems platform are displayed for review by Wafler Farms crews and managers in Wayne County, New York. (TJ Mullinax/Good Fruit Grower)

Extras

What if you were able to determine exactly where the best and worst yields were within any given block or row?

To that end, Howitt’s team mounted four load cells — electronic devices that measure weight — to the platform, one on each corner.

As weight is added, the metal in the device is stressed. It responds to the stress by sending out an electrical current that is interpreted by the processor to determine the increase in bin weights.

This data will enable them to create a yield map of an orchard.

Next, Wafler asked if they could determine where each of the platforms was, at any given time, on his farms.

That solution was a relatively easy one: They added a GPS system.

It’s still a work in progress, with the current challenge being communication.

Since Wafler Farms consists of a number of locations over several miles of northwestern New York countryside, they need to devise a means of transmitting that data continuously to the communication hub.

The very low speed at which the mobile platform moves — 7 feet per minute — made accurate GPS tracking difficult. They solved that by adding a computer to work off the wheels, tracking both speed and distance.

Now the Waflers can graph its movement for every minute it is in motion based on computer reports sent to the processor once a second.

The downside is that data is stored on the platform with the video data and can’t be analyzed until the end of the day.

That’s why the Agrinetix technical staff is currently looking at building a wireless network for real-time reporting. •

– by Dave Weinstock

Leave A Comment