In almost every orchard, there are trees failing to reach their full potential.

Variable-rate nutrient applications could be one way to help weaker areas catch up with the rest of the block.

“We need to put the right nutrients in the right place at the right time at the right rate to maximize tree health within the block,” said Jill Tonne, a crop consultant with Nutrien Ag Solutions. That 4R principle is well established in agronomy, but new technology, new environmental concerns and new interest in precision agriculture is creating more interest in how variable-rate applications could boost orchard efficiency.

The concept itself is not new, she said, citing electrical conductivity maps long used to understand physical soil variability. But newer technologies, such as the SoilOptix sensor made specifically to measure soil nutrients, have made it more reliable to design management zones.

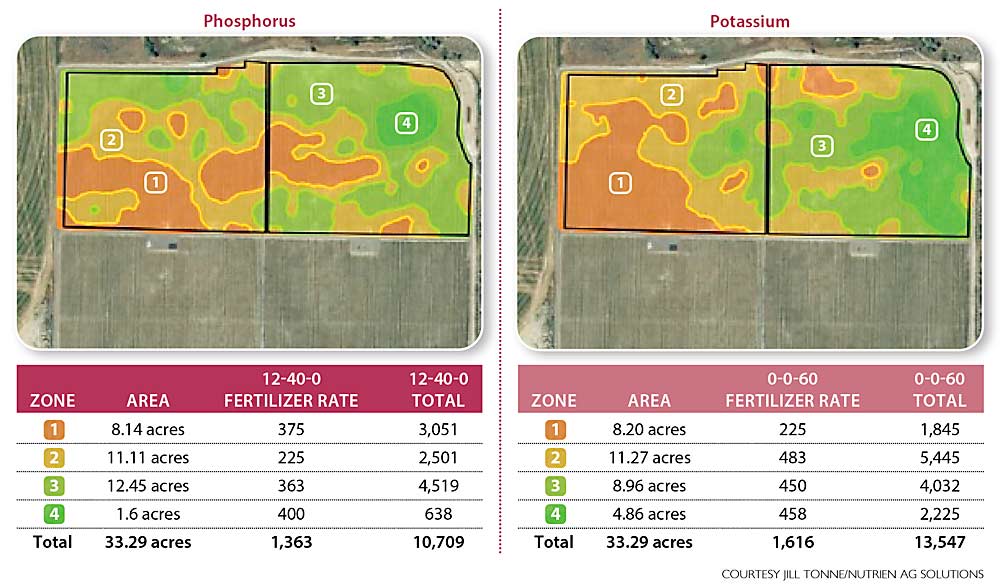

During field days on smart orchard technology last summer, Tonne shared an example of a grower who used SoilOptix scans to inform variable-rate phosphorus and potassium applications in an apple orchard. Rates varied from 225 pounds per acre to 500 pounds per acre for both; the grower applied nitrogen and other micronutrients at a flat rate. In a second example, an organic orchard’s variable application was based off aerial imaging to set the zones.

“I take out everything that is consistent across the block for a flat-rate blend,” Tonne said, which is cheaper for the grower to do themselves, while Nutrien provides the variable-rate application as a service with its specialized GPS-equipped spreader that adjusts rates according to the task map. “If we need to do pH adjustments with sulfur or lime, and our NPK, those are the ones that make the biggest difference. We could go out and variable-rate boron, but there’s not enough variation.”

Meanwhile, Wilbur-Ellis agronomists have their eyes on a smart spreader from South Africa that adjusts rates automatically, based on input from imaging-derived maps that show the variability and input from agronomists on what to do about it.

“In order to address the variability, you need to have equipment that can apply in a variable rate,” said Paolo Sanguankeo, technology development specialist for Wilbur-Ellis. Last season, he worked with a spreader from Red Ant Agricultural Equipment, which has been making ag machinery in South Africa since the 1960s.

The version used in that market was too small for the way Washington orchards apply fertilizer, he said. Labor costs pushed U.S. growers toward two to three passes of blended products, plus drip fertigation, whereas in South Africa growers tend to spoon-feed trees with more frequent passes of granular product.

So, Wilbur-Ellis worked with Red Ant’s lead engineer, James Reid, to design a Washington-scale spreader for testing this season. It was sitting at the port in Seattle when this issue went to press.

That version has a larger hopper, divided into two holds, and the ability to make precision applications of two products in one pass, Reid said. Technologically, it’s the same as the smaller model that has been on the market in South Africa for several years and meters out fertilizer according to a task map on a Bluetooth-linked smartphone app. To keep costs down, the spreaders can use the phone’s GPS too, though newer, affordable precision GNSS modules can be added on as well to improve accuracy, Reid said.

“That’s where we are making a difference is the ability to provide precise equipment (while) keeping the pricing point in the ballpark,” of a traditional orchard spreader, Reid said.

The fan that blows out the product can also be calibrated to control placement, from a narrow band to a wide swath, whether growers use it for variable-rate or flat-rate applications.

Reid also developed retrofit systems for hydraulic spreaders that control belt speed as well as wheel-driven spreaders “that can literally take over the gate and move it up and down,” he said.

“There is a big win if you can take equipment that farmers already have and give them a new life with some precision capabilities,” Reid said. “It doesn’t have to be state-of-the-art tree-level to be valuable.”

Growers can generate task maps for Red Ant spreaders from many imaging companies, such as South African tech company Aerobotics.

“Where we’ve seen success in the local market in SA is we’re using aerial, NDVI assessment and soil assessment,” Reid said. The technology allows them to define zones with different soils that need different treatment, in terms of nutrition and irrigation, to get similar production.

Growers might find some small product savings, maybe 5 or 10 percent, Reid said, if they were overapplying on average to meet the needs of the higher zones.

Tonne said that in her experience, the savings on inputs “is a wash” as they adjust to higher rates in some areas and lower in others. The value comes from “trying to maximize these areas that are weak to get those blocks up to capacity,” she said. “Realistically, I try to focus on the higher-value crops that can justify the expense.”

Sanguankeo suspects the value of variable-rate application will be found in conjunction with other orchard practices that address weak areas.

“This is holistic. It’s not just fertilizer to stimulate growth — it’s soil health, soil water-holding capacity, irrigation, mulching,” he said. “Applying nutrients is part of the bigger picture; that’s why agronomists have their jobs.”

In a trial last year in a Fuji orchard, they had areas with good soils where the trees were too vigorous, as well as areas with poor soils where trees weren’t growing.

“What we learned is that you can cut back in the areas you want to dial back and apply higher in areas that are underperforming,” he said, but changing up irrigation and mulching was also needed to improve the weak areas. “When we are dealing with chronic problems where trees have been struggling for years, we are not going to see results quickly.”

—by Kate Prengaman

Leave A Comment