Successful orchard mechanization requires a narrow, uniform canopy for efficient pruning and picking with platforms — now and for eventual automation.

In Washington, progressive growers are planting new orchards in a variety of systems as they aim for a fruiting wall-style canopy. But not everyone has the capital to start over with new plantings.

That’s why in New York, some growers turned to hedging to convert traditional tall spindle trees with decidedly 3D canopies to a narrower system that’s better for mechanization. Cornell Cooperative Extension horticulturist Mario Miranda Sazo shared the findings of his trials converting to 2D canopies at the Washington State Tree Fruit Association’s annual meeting in December in Yakima, Washington.

“There is an opportunity for big, mature canopies to bring them to 2D,” Miranda Sazo said. “The fruiting wall is more uniform, more efficient and fully suitable for orchard mechanization. And for us in New York, mechanization is the only way for us to stay in business.”

But you can’t just run mechanical pruners through your block and call it converted, he cautioned. He tried an aggressive, single-year conversion several years ago and doesn’t recommend it. Instead, he presented a schedule for preparing a mature orchard for transition — over several years — that’s been much more successful.

“Mechanical pruning doesn’t mean that hand pruning is not needed. In reality, you have to start with pruning manually,” he said. Removing the large wood, with two to four cuts per winter, over a few years, sets the trees up well for mechanical pruning without sacrificing yield.

This transition time is especially important for New York growers whose early high-density plantings suffered from a lack of strong renewal pruning, Miranda Sazo explained in a follow-up interview with Good Fruit Grower.

“If you don’t do good systematic annual pruning, you very quickly start building a bushy canopy and growing wood instead of fruit,” he said.

When pruning out the big branches, he recommends leaving a stub close to the trunk to allow better light penetration in a narrower canopy and create a fruiting unit. Then with the large-caliper wood cut out, it’s time for a mechanical pruning pass at the end of the dormant season.

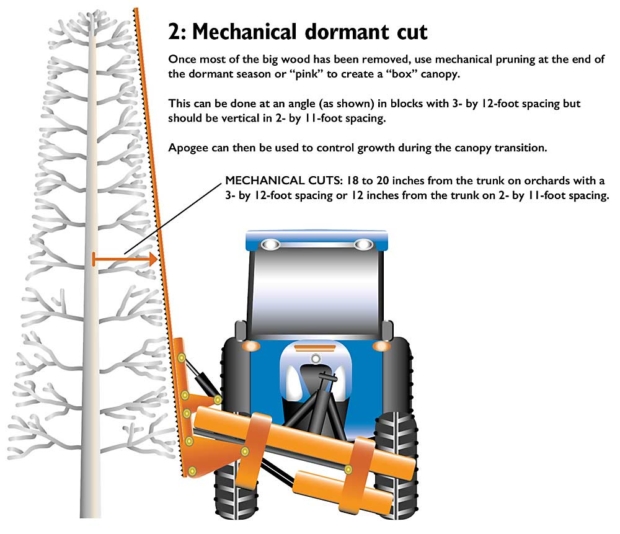

Miranda Sazo recommends pruning at 18 to 20 inches from the trunks in orchards planted at 3 feet by 12 feet. For 2-by-11 plantings, he recommends pruning at just 12 inches.

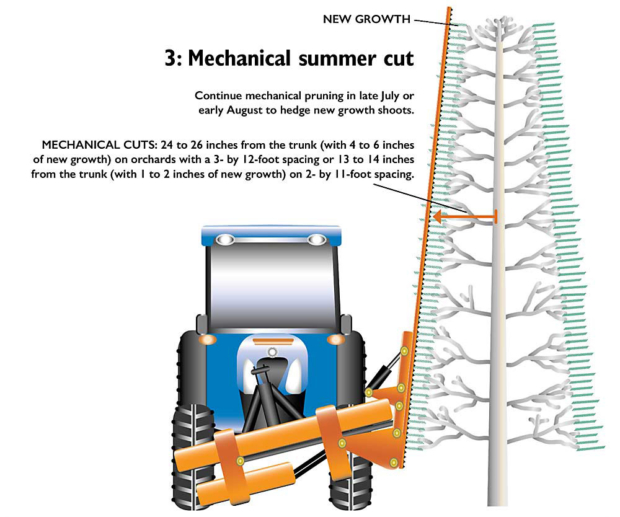

Then, summer hedging of the new shoots maintains the box-shaped canopy. Miranda Sazo recommends hedging to leave just 4 to 6 inches of shoot growth for the 3-by-12 plantings and just 1 to 2 inches of shoot growth on 2-by-11 plantings.

The resulting narrow canopy is well-suited for efficient platform-based harvest and produces more uniform, high-quality fruit. The success of his initial trials with Lamont Fruit Farms in Waterport, New York, have encouraged other growers throughout the Lake Ontario region to make the transition as well.

“I’ve lost count of how many mechanical pruners have been bought or developed by Lake Ontario fruit growers, so it’s significant,” Miranda Sazo said. “So, they are believers.”

Lamont Fruit Farms co-owner Jason Woodworth said that the switch to managing the canopy this way was driven more by gains in fruit quality than reduction of labor costs.

“Overall, the fruit quality has been spectacular, the interception of sunlight has been great, and we leave very little fruit behind for under-color anymore,” Woodworth said. “The goal is to get every apple we grow.”

The interior of the tree row still requires hand pruning, but with the box canopy already set with the sickle bar, pruning crews can see the ideal canopy structure more clearly and do a better job, Woodworth said.

“It’s created an all-new depth of detail pruning,” he said.

Miranda Sazo agreed. “It’s a pursuit of precision because we want a better bud density in the canopy, and we need human eyes to see the buds and make those decisions,” he said.

At Lamont Fruit Farms, where many blocks were already planted at 2 feet by 11 feet with a relatively narrow canopy, the transition was less dramatic and less risky than for some of his neighbors with wider spacings and much larger canopies, Woodworth said.

For example, his brother had a block planted at 14 feet by 3 feet with a canopy so wide you could barely drive a tractor down the row, he said. The successful transition required a lot of bud counting to make sure the new, narrow canopy could succeed.

“For spacings that are wider, you certainly have to start by counting buds to make sure you have enough fruit to hold your vigor at bay,” Woodworth said. “It’s all calibration and you have to calibrate for how many bins per acre you want to end up with and what you can live with.”

Now, six or seven years after making the switch, Woodworth said the 2D canopy is paying off in terms of uniformity in the orchard and making it work for platforms. “In my mind, you can’t have one without the other,” he said of hedging and platforms.

Though pruning without people is still impossible with today’s technology, taking these steps toward increased mechanization now is imperative, Miranda Sazo said, both due to labor shortages and the need to have orchards ready for more emerging technology.

“I love to help growers make more money, and we need to help growers incorporate more mechanization for higher labor efficiency,” he said. “I don’t want to be waiting for robotics.” •

—by Kate Prengaman

Leave A Comment