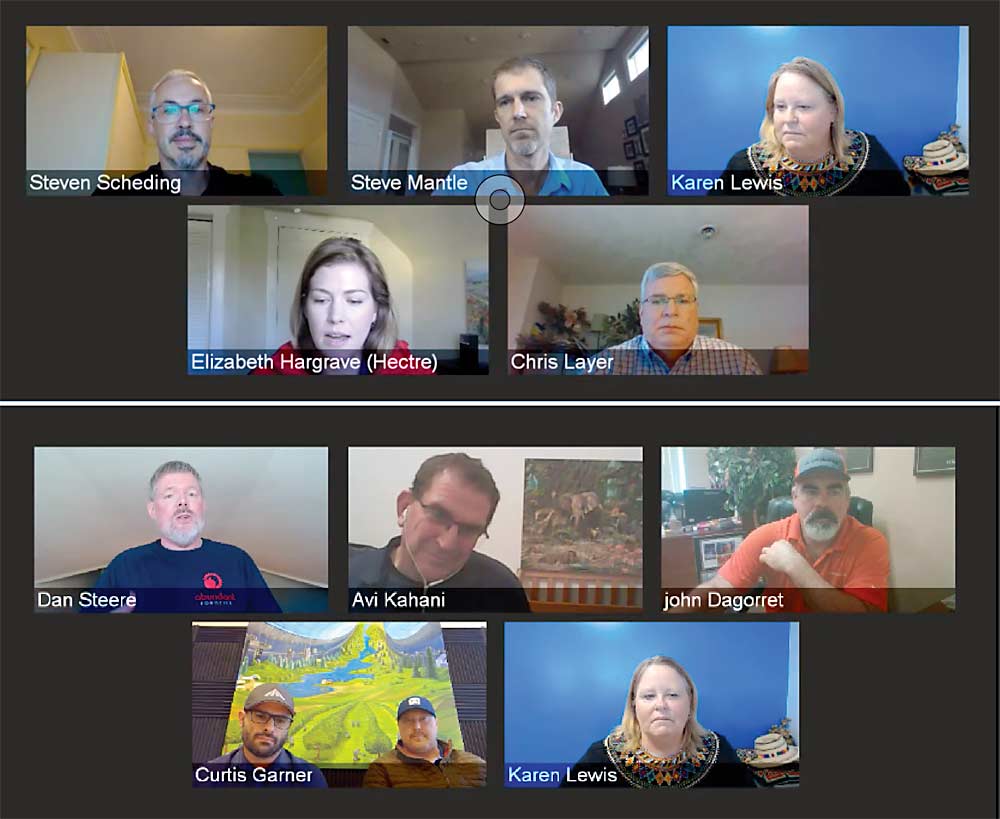

It wouldn’t be an International Fruit Tree Association meeting without an opportunity to talk technology, so the final session of the organization’s virtual meeting on Feb. 24 featured short presentations from eight established and emerging tech companies looking to support the tree fruit industry from bud to bin.

Jeff Cleveringa, IFTA vice chair and the head of research and technology for Starr Ranch Growers, said that while many of the technologies shared today are not quite yet available commercially, it’s important for growers to know what’s coming and how they can get their orchards ready.

Leaders of three harvest companies, Abundant Robotics, FFRobotics and Automated Ag, shared updates on the robotic harvest and harvest assist technologies nearing commercialization.

For Abundant Robotics, 2020 was a milestone year, CEO Dan Steere said. The company harvested over a million apples in Washington — enough data to show that the technology can pick at packouts comparable to hand harvest. He declined to share cost or productivity details, citing an upcoming company announcement.

“We’re happy to say the productivity metrics are on the path to offer a commercial service at a cost equal to or less than the cost of handpicked fruit,” he said.

The pandemic prevented FFRobotics from conducting harvest trials in Washington in 2020, but the company is continuing development of technology that will eventually allow the machine’s picking arms to be replaced for pruning or thinning tasks and also developing ways to use the data collected by the robot’s camera systems, all to provide more value to growers, said company spokesman Pat Pinkston.

Both companies said they plan to offer the technology as a custom harvest service, at least in the near term.

Growers should be able to purchase the apple vacuum harvest assist platform, the Bandit Cyclone, in late 2021, said JJ Dagorret, owner of Automated Ag, one of the partners in the Bandit Cyclone.

During Q&A, an audience member asked what tree systems work best for these technologies.

Avi Kahani, CEO of FFRobotics, said narrow, vertical systems work best, as it can be a challenge to access fruit inside of V systems.

For the Bandit Cyclone, narrow systems work best, either vertical or V-trellis. “I see the most efficiency when our guys can pick through the tree from 6 feet up and skip the other side,” Dagorret said.

Steere said that while it would be nice to have a specific a system, Abundant engineered its harvest robot to work in all three common apple systems: tall spindle and formally trained vertical and V systems.

A second group of companies focused on data-driven farming and vision-based technologies included Verdant Robotics, Hectre, Moog Inc., Innov8.ag and Green Atlas Group.

Verdant Robotics wants to help growers optimize crop value by tracking bloom using robots that can target king bloom with precision spraying of fertilizer and pollen, and also target side bloom with thinners.

“We can shift the packout by babysitting each apple,” said company co-founder Gabe Sibley. “It’s not just about labor cost savings, it’s about the value that’s not possible without what digitization enables.”

Similarly, Moog is looking to help growers with precision crop load management by using vision systems to count buds on every tree and share that information to guide workers to do better precision pruning and thinning, said principal engineer Chris Layer. The Buffalo, New York-based engineering company is primarily an aerospace and defense contractor, but it recently found opportunities to work on autonomous vehicle navigation and vision technology in agriculture.

Layer shared data from two years of trials in Western New York apple orchards.

Another vision-based company, Australia-based Green Atlas, offers mapping of flowers and fruit counts throughout the season. The company’s ATV-mounted camera system can quickly cover an orchard, capturing crop load variability to help growers manage more precisely, said company co-founder Steve Scheding.

The company is working successfully in a wide variety of orchard crops, including kiwifruits, cherries, grapes and nuts, including large Macadamia nut trees, Scheding said.

Steve Mantle, founder of Walla Walla, Washington-based Innov8.ag, shared insights from the Smart Orchard project his company launched with the Washington Tree Fruit Research Commission, Washington State University and a variety of sensor companies to evaluate the potential benefits of sensor-based management for data-driven fruit farming. Innov8.ag partners with other tech companies to help integrate data to simplify decisions for growers, Mantle said, and the company plans to collaborate with Green Atlas this season.

New Zealand-based Hectre develops orchard management software. The company’s business development manager, Elizabeth Hargrave, shared how the Spectre app uses smartphones or iPad cameras to help growers gather quality data during harvest. By taking bin photos, the system provides sizing and color estimation in real time — no need to wait for packout data from the warehouse, she said. The system is already developed for all the core varieties, but it can be trained to work with any apple varieties, and pears as well.

—by Kate Prengaman

Leave A Comment