Chelan Fruit Cooperative, one of the largest packers of Rainier cherries in Washington State, built a new packing facility this year that was specially designed to handle the delicate yellow cherry variety.

Chelan Fruit, which has 300 grower members, was set to pack about 9,500 tons of cherries this year, including 1,000 tons of Rainier. It also expects to pack around 425,000 bins of apples.

Dale Davis, director of special projects, said the cooperative’s Rainier tonnage has been increasing exponentially, and the decision to build the new facility came after it acquired Orondo Fruit Company, which also had a large volume of Rainiers.

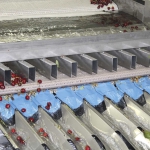

Van Doren Sales and Compac, which have been working together for 15 years, built and equipped the line. It features Compac optical color sorting and sizing systems and both internal and external defect sorting.

David Buys, international sales director for Compac, which is based in New Zealand, said most of the electronics and optics came from New Zealand, while the stainless steel components came from Yakima, Washington.

The cherries are singulated in water, and most of the drops on the line are water transfers that cushion the cherries. The system can handle more than five tons an hour of Rainier cherries or eight tons per hour of red varieties.

Van Doren and Compac installed similar lines—though primarily for red cherries—at Tangaro Ventures, Ltd. and B.C. Tree Fruits in British Columbia, Canada, and at Columbia Fruit Packers in Wenatchee, Washington. The Columbia Fruit line has a 36-lane sizer.

Leave A Comment