In the storages and packing house at Auvil Fruit Co., the workers call it “magic water.” They use it to clean storages and bins before bringing in new bins of apples at the start of harvest and to sanitize apples and sorting and packing equipment routinely during the packing process.

In a U.S. Department of Agriculture study report, it was called “shockingly powerful.”

So what is this magic water?

The real name is electrolyzed water, and it is gaining traction in many places in the food industry and in the health care industry as well. It is a user-friendly replacement for chlorine, ozone, and detergents.

Walt Hough, the plant operations manager at Auvil, says, “I’m a believer. I have a high level of confidence that we have a food safety plan that works. It works not only against pathogens that can harm humans, it works against molds and yeasts that cause fruit decay in storages.

“Not only does it let me sleep better at night, we can assure our customers that they are buying a clean product that will have a longer shelf life. We can document that.”

In his 38 years at Auvil, Hough had felt frustrated that Hazard Analysis and Critical Control Points (HACCP) plans didn’t really offer assurance that effective measures were being applied at those critical contamination points. The reliance on solutions containing chlorine is near total.

The history

Hough began reading the literature about electrolyzed water about five years ago and adopted it two years later.

The Japanese began using it in the mid-1980s to kill bacteria and parasites associated with fish. Then they began using it in hospitals. Since then, research has shown it can be used on fresh produce since it has no effect on quality characteristics like taste, odor, or texture.

It can be used in mist water in supermarket produce displays. It can be used to spray carcasses in meat slaughter facilities to kill organisms like Escherichia coli (E. coli).

Home units for making electrolyzed water are being sold as a germ-free alternative to ordinary tap water, and it is said to have energizing powers. It is safe to consume and harmless to people’s skin and lungs.

It’s being tried outside, in orchards as well. It is being studied as a tool for control of mildew in cherry orchards and to kill fire blight bacteria in apple and pear orchards, Hough said.

It is safe for workers to use. And, when it has done its work, it resumes its role as ordinary water, easy to dispose of or use for other purposes.

The Auvil Fruit Company website has this to say:

“Auvil Fruit has implemented a system which utilizes special equipment to restructure the molecules of water, creating two waters with different pH levels—high pH alkaline water and low pH acidic water. The high pH water is used to wash fruit during the packing process and clean machines and other equipment in our packing facility. The low pH water is used to kill bacteria and microbial organisms on fruit and in cold storage buildings. This electrolyzed water is 100 percent environmentally safe, and greatly minimizes the use of chemical cleaning agents, thereby increasing food safety.”

One other Washington apple company—McDougall & Sons, Wenatchee—has also installed the system, and one is being planned at Gebbers Farms, according to a sales representative for the company that makes the systems the orchard companies are installing.

The chemistry

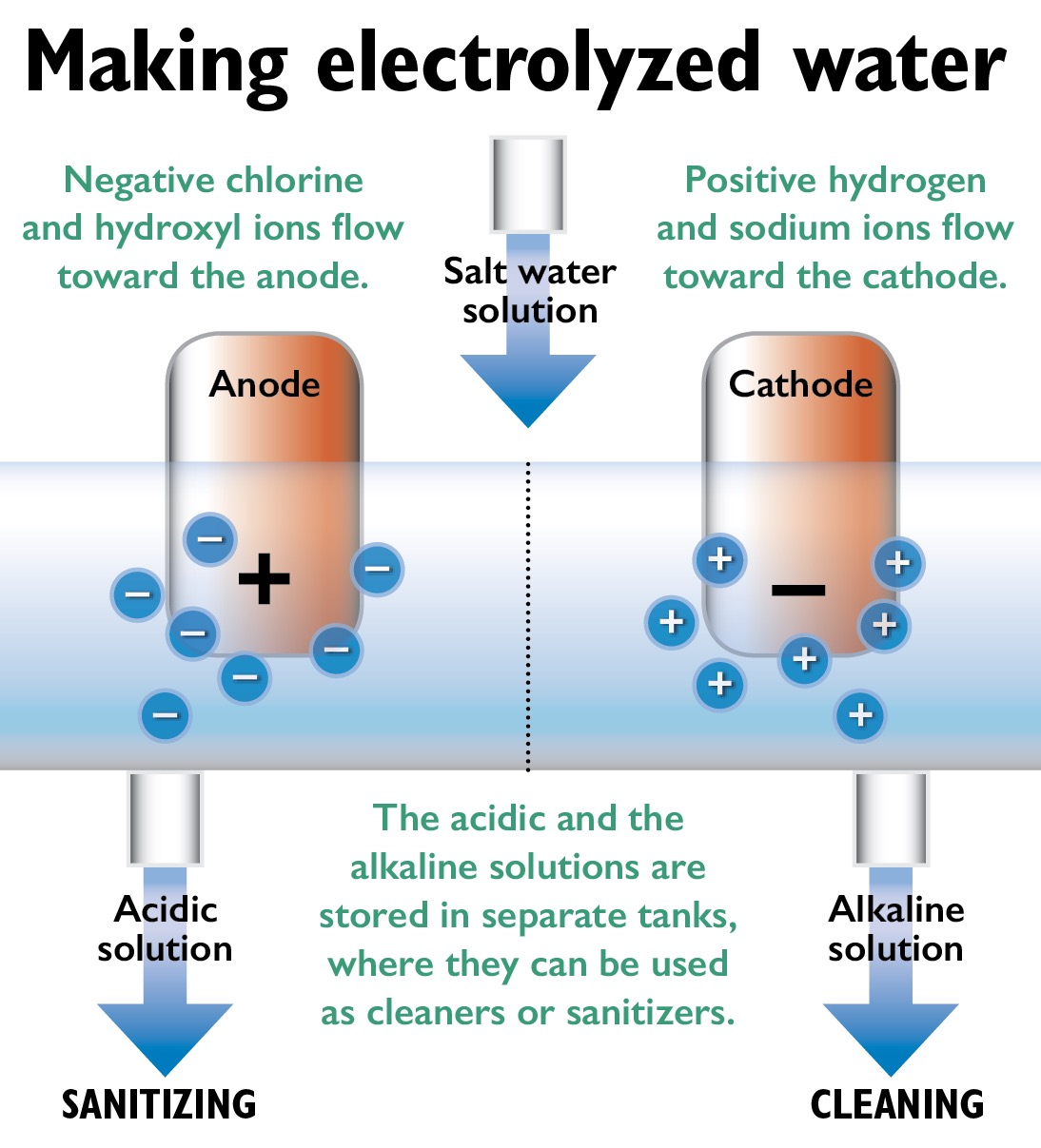

When an electric current is passed through water containing a small amount of table salt, both the water and the salt are broken into ions. Positive hydrogen and sodium ions flow toward the cathode, while negative chlorine and hydroxyl ions flow to the anode.

The water at the hydrogen end becomes acidic; at the hydroxyl end, it becomes alkaline. The acid and the alkaline products of the electrolysis are collected separately and stored in separate tanks, where they can be used as cleaners and sanitizers (see figure).

In the Auvil arrangement, Hough said, about 3,500 gallons of this “magic water” are made each day. The alkaline water is used to wash the apples and the equipment and the acid water is used to rinse. When the two waters recombine, the acid and alkaline neutralize each other and ordinary, slightly salty, water remains.

“We could run it right back into a stream,” Hough said. “There’s nothing in it that will hurt a fish.” Auvil makes apple cider in a separate operation, where electrolyzed water is used to clean pasteurizer plates.

The waters are applied at high pressure at four critical places in the packing line, once every hour, to keep it clean and germ-free.

“We no longer use detergents to clean,” Hough said. “We have three years of documentation. Swab tests not only come back low, they come back showing nothing, no bacterial growth at all.

“We have the equipment to make and store 3,500 gallons,” he said. “We only run one shift per day, but by running the equipment all the time, we can get by with a smaller generating unit that will handle the one packing shift.”

They pack 600 to 800 bins per shift. The electrolyzed water is recaptured so it can be used three times before it loses its antimicrobial activity and needs to be replaced with new water.

As most people in the fruit industry know, apples are not considered a major source of bacteria that cause human illnesses. In apple packing systems, Hough said, the real battle is against yeasts and molds that cause decay. “Other pathogens, human pathogens, die easier.”

So, for Hough, the payback from electrolyzed water will come from better packouts as less fruit deteriorates in storage from rots caused by yeasts, molds, and fungi. It will help Auvil Fruit achieve its sustainability goals and its desire to supply customers with “Gee Whiz Fruit,” the high-quality, tree-ripened fruit consumers want.

Lease

Wil Fiedler, a sales representative for the Ernest F. Mariani Company in Salt Lake City, Utah, that sells the units, said a unit like the one at Auvil would cost from $110,000 to $130,000. Cost of operation is the electricity required. Auvil chose to lease the equipment rather than purchase it.

The equipment is produced by EAU Technologies, Inc., and is used to produce what the company calls “empowered water.” One of its customers is Coca Cola, which uses it in clean-in-place systems in soft drink bottling plants.

The company claims the water replaces dangerous chemicals, improves microbial killing power, reduces waste water generation, lowers costs of wastewater treatment, works without heat so it lowers energy use, is non-toxic—and “contributes to corporate sustainability objectives.” That last advantage means something at Auvil Fruit.

In addition, electrolyzed water is a “physical kill” process, to which disease organisms cannot become resistant.

EAU labels two of its empowered water products Primicide A and Primicide B. Primicide A is the acid product, with a pH of about 2.5, that is very reactive—“as effective as ozone and irradiation as a surface disinfectant.”

Primicide B is alkaline, with a pH about 11.5 and has cleaning properties, replacing chemical detergents, as well as having anti-microbial properties.

—by Richard Lehnert

Leave A Comment