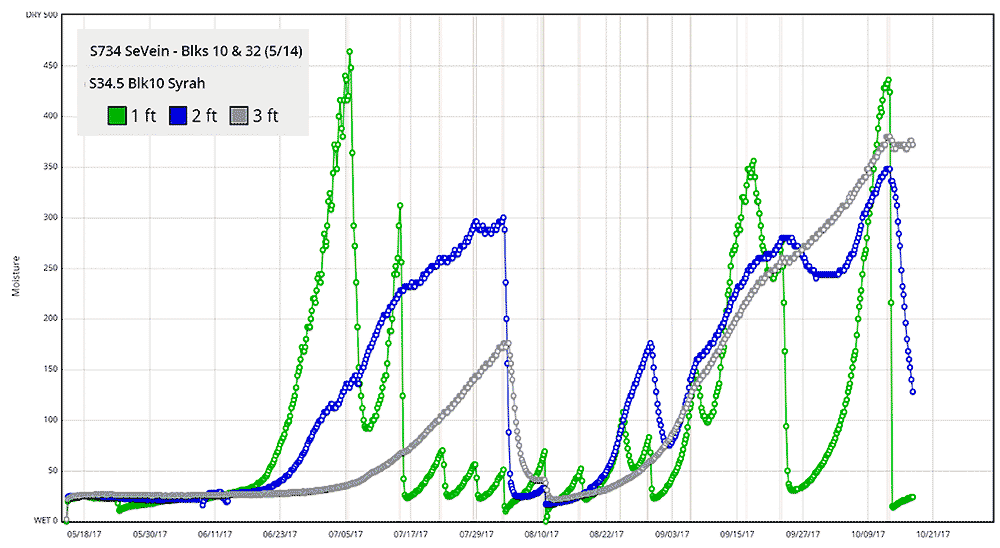

Using inexpensive soil tension sensors at 1-, 2- and 3-foot depths can give growers insight into how hard grapevines are working to pull water from the soil, providing a more efficient method for estimating the plants’ water stress to guide deficit irrigation practices, compared to using a pressure bomb to measure stem water potential, according to vineyard consultant Alan Campbell. His company, SmartVineyards, aims to help growers incorporate detailed soil moisture data into their management. (Courtesy Alan Campbell)

The engineer-turned-grower has hundreds of soil water-volume sensors spread across his 100-acre Ciel du Cheval vineyard on Washington’s Red Mountain, and he tracks the trends in soil moisture at varying depths to understand the vines’ water stress and make better irrigation decisions.

Jim Holmes

What matters is not the numbers — the exact soil water volume — but the trends and how it changes over time, he said.

“If the number is changing quickly, the vine is using a lot of water. If the number is changing very slowly, the vine is having trouble getting water out of the soil,” Holmes said.

“Not only can we measure what is happening in the plant, we can probably manipulate it to produce a better-quality grape,” he said. “The number-crunching helps you find predictive relationships for how soil moisture gradients affect the vine.”

When Holmes explains his data-driven approach to his neighbors, however, “their eyes glaze over,” he said. That’s perhaps because exotic mathematics aren’t a common hobby for grape growers.

But vineyard consultant and physiologist Alan Campbell believes that with the right sensors and algorithms to interpret the data, less-mathematically inclined growers could get the same benefits from vine-stress-informed management.

He’s one of many service providers and researchers aiming to meet the industry’s needs for data to guide irrigation, but one of the only ones looking to use artificial intelligence to learn from the best vineyard managers and identify patterns of precision irrigation to meet canopy management and fruit quality goals.

“Vineyard managers need better tools for managing vine stress,” Campbell said. Using a pressure bomb to measure stem water potential is time-consuming and expensive, so even growers who buy the equipment end up rarely using it, he said. “The reason the leaf increases in tension is to pull water from the soil, so why not measure and manage the water in the soil instead?”

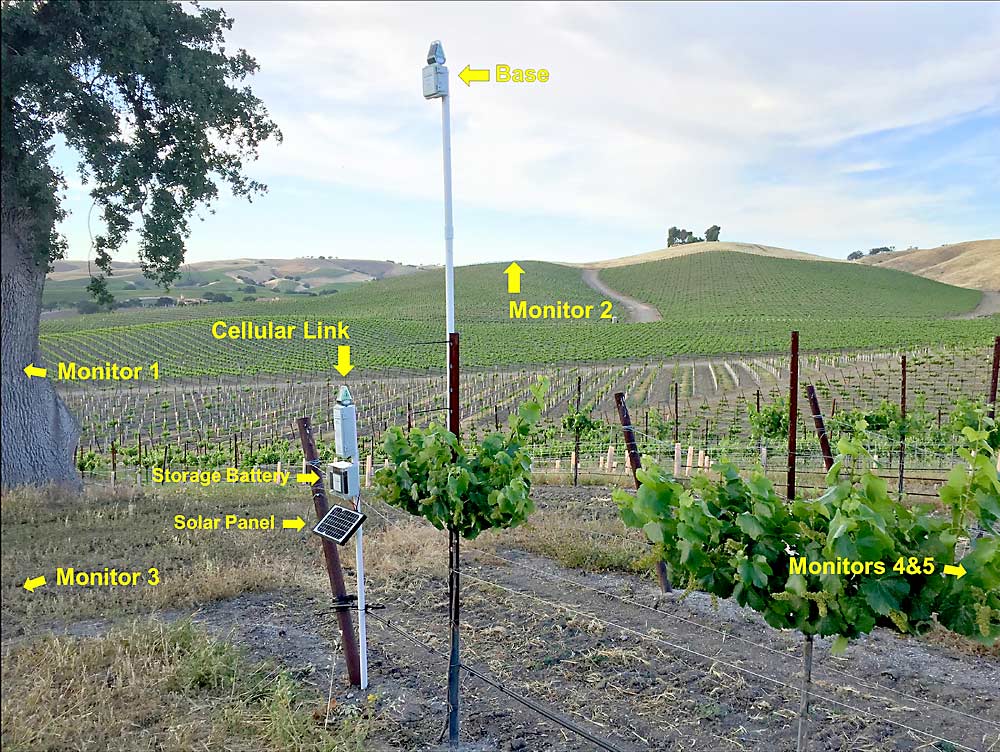

SmartVineyard’s system uses three Watermark sensors, made by Irro-meter, to track how hard vines have to work to pull water from the soil. (Courtesy Alan Campbell)

In 2013, he formed a company, SmartVineyards, to do just that. He spent the years since refining his approach to using soil tension sensors and telemetry systems to transmit data. Electronic tension sensors are cheaper to operate than volume sensors, Campbell said, and his own research shows a greater than 90 percent correlation between the soil tension and the stem water potential.

The first year using the sensors, Campbell recommends growers simply track soil tension as they irrigate normally and identify key target points for management. “You can use the sensor readings to replicate a successful year, or change the strategy,” he said.

Alan Campbell

There’s a need in the wine grape industry for this data-driven irrigation management, said Markus Keller, professor of viticulture at Washington State University. He couldn’t comment on the specifics of Campbell’s system, but said that broadly, the soil data approach should benefit growers if they can afford to install the systems.

“I have been pushing for years now that growers need a better handle on how to schedule irrigation,” Keller said. “They need better tools. It’s one of the top industry research priorities.”

Holmes said using soil moisture data to irrigate is now so integral to his management that “we feel naked if we don’t have this information now.”

Campbell began working with Holmes because the data set that Ciel du Cheval has accumulated on soil moisture and irrigation is a treasure trove for the analysis Campbell wants to offer his clients. But Holmes approaches the issue with soil water-volume sensors, which are a more expensive investment, but which tell a similar story.

“We’ve been instrumenting our vineyard since the beginning and the reason for that is that we had no idea what we were doing,” said Holmes, who first planted grapes in 1975 when he was working full time as an engineer at Hanford. “To make up for that, we tried to measure everything we could in the biological world.”

Advances in telemetry mean more sensor data can be transmitted across large vineyards with less equipment. This photo shows an installation in Paso Robles, California. (Courtesy Alan Campbell)

In those days, water was hard to get on Red Mountain. “Other folks were putting 20 inches of water on and we had to get away with 12, so we learned a great deal,” he said.

Back then, Holmes checked his manual soil sensors once a week, recording and analyzing the data by hand. Now, automated recording every 15 minutes at six depths, from 8 inches to 48 inches, are beamed to the cloud so he can pour over the graphs in his office, watching the vines pull water from deeper and deeper down the soil profile over time.

This chart shows the soil moisture data for a vineyard in Washington’s Walla Walla Valley and shows how the irrigation schedule changes the available water throughout the soil profile. Each spike of the green line represents an irrigation application as seen in the shallow soils, while the gray line shows the more stable trends in the deeper soil. (Courtesy Alan Campbell)

But Campbell wants to take it a step further.

“We want to provide guidance, not just data, to growers,” he said, so he teamed up with researchers at Oregon State University to apply principles of machine learning to the soil water data and find management patterns and strategies. “Could we teach a computer to be Jim, to look at the data every day and make the same decisions to irrigate — that Jim would?”

So far, it’s promising, Campbell said, and the company and its university collaborators are seeking research grants to further develop the approach and test it in other irrigated crops.

Holmes doesn’t need a computer to be him, of course. But he’s intrigued by Campbell’s idea that artificial intelligence can find new patterns in the data and, by linking with weather forecasts, make predictions about how you may want to irrigate in the future.

And when vineyards lose longtime managers, their knowledge of how to irrigate to optimize fruit quality goes with them. Campbell’s approach promises to capture that institutional knowledge for future generations of growers. •

—by Kate Prengaman

Leave A Comment