Climate change, invasive pests and diseases, labor shortages and shifting consumer tastes will be the biggest challenges facing New York viticulturists in the future, but with those challenges come new opportunities.

Two experts discussed the changing landscape of the grape and wine industry during B.E.V. NY, the New York industry’s annual conference, held virtually in March.

Baby boomers, the leading wine consumers in recent decades, are getting older, and younger generations just don’t drink as much wine, said Russell Smithyman, a viticulturist and consultant based in Washington state and chair of the National Grape Research Alliance. The result: Demand for mainstays like Cabernet Sauvignon, Chardonnay, Merlot and Riesling has declined.

However, shifting consumer tastes create opportunities. Younger consumers are open to trying different wine styles and flavors, which opens the door to new varieties, progressive growing techniques and innovative winemaking methods, Smithyman said.

Future viticulturists will need to take a multidisciplinary approach to managing vineyards, one that includes data and technology management; fortunately, younger viticulturists are more tech-savvy than their more experienced counterparts.

Reductions in hand labor will lead to greater reliance on machine labor. Mechanization has a reputation for producing lower-quality grapes in the wine world, but improving technologies are changing that perception, he said.

“Harvesters have gotten so much better in the past decade,” Smithyman said. “Fruit quality is similar to hand harvest.”

Remote sensing and other precision viticulture technologies can capture huge quantities of vineyard data, and artificial intelligence can use that data to build more accurate crop models. Water status, vine nutrients, fruit sugars — these and other vineyard factors are being measured in greater detail, he said.

New technologies better measure variability within vineyard blocks, so growers know where to make changes that will lead to more uniform production. Growers are exploring controlled viticulture — enclosing vines with tunnels or nets — as well as new pest and disease detection methods. Dogs are being trained to detect diseases in citrus crops, and perhaps the same can be done in vineyards.

“The viticulturist of the future has to take all that data and decide what to do with it,” Smithyman said.

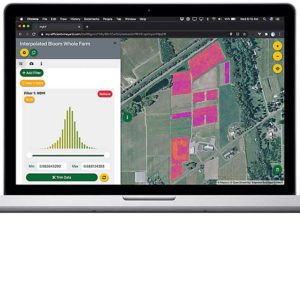

Terry Bates, director of the Cornell Lake Erie Research and Extension Laboratory, said the future — precision viticulture — is already here. Drones fly over vineyards, measuring the nitrogen and potassium status of vines. Robotic pruners are being tested. Data processing is more sophisticated yet simpler to use.

Management practices can be more nuanced than ever, as growers use spatial data to split vineyards into zones and manage each zone based on its geography, soil and other characteristics, rather than managing the entire vineyard the exact same way. Potential is growing for vine-by-vine management, though Bates isn’t sure growers want to deal with that level of detail.

But when yields in a single grape block can range from 3 tons to 16 tons per acre, for example, it underscores the importance of vineyard variability and nonuniform management practices, he said.

Bates said Cornell has developed a “measure, model and manage” approach to vineyard management: Use sensors to measure key variables, create a predicted-yield model based on that data, and manage the vineyard according to the model.

Cornell’s MyEV software, a suite of online tools that helps vineyardists collect, organize, map and analyze layers of vineyard data, is one of the tools that can help growers achieve vine balance and higher fruit quality at harvest time, he said. Find the free tool at: efficientvineyard.com.

Bates said any truly comprehensive vineyard management plan must combine precision viticulture findings with local viticultural knowledge. Sophisticated commercial sensors can tell you a lot about a vineyard, but there are quirks only a grower can know about. That knowledge should be added to crop models, he said.

“Anything you think affects yield, put it in,” he said.

—by Matt Milkovich

Leave A Comment