Asking a tree its level of stress used to be the provenance of scientists with carefully calibrated equipment.

But new technology puts such sensors in the hands of growers. Some companies pair traditional research tools, such as dendrometers, with new algorithms and apps to make them more accessible, while others have developed brand new tools.

“It’s critical, as new sensors become available to growers, there needs to be unbiased evaluation of their value to the industry,” said Lee Kalcsits, endowed chair for tree fruit environmental physiology and management at Washington State University. He and postdoctoral researcher Victor Blanco set out to do such an evaluation in apple and pear orchards in 2021 and 2022, with support from the Washington Tree Fruit Research Commission, and they recently shared their results with the industry.

Kalcsits and Blanco looked at three types of sensors: dendrometers (used on both trunks and growing fruit), sap flow sensors and microtensiometers. All assess plant water status directly.

“If you want to irrigate based on a threshold value, it’s always better to base it on the plant stress, not environmental conditions,” such as evapotranspiration rates or soil moisture levels, Blanco said. “Knowing exactly the water you need is important so you can make decisions based on information.”

Microtensiometers are the newest tool. California-based FloraPulse commercialized the technology developed at Cornell University. The sensors are installed into the trunk at the start of the season and provide real-time updates of trunk water potential, which is a direct measure of the water tension. The sensors offer an alternative to manual pressure bomb tests — the gold standard for assessing plant water stress, Blanco said.

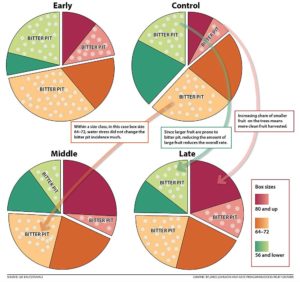

Blanco and Kalcsits found that the FloraPulse sensors offered highly accurate and precise measurements, comparable to the pressure bomb. The data can be used to guide deficit irrigation programs, such as those to reduce vigor, fruit size and bitter pit in Honeycrisp.

While they are excited about the new tool, Blanco said they also want to see how long the sensors, which are relatively expensive, can last in Washington orchards. Most of the testing and early commercial use has been in California, where freezing winter temperatures don’t pose a threat. Blanco wants to see if the sensors can be reinstalled after being removed for the winter. The tree trunks also need to be at least 2 inches wide to accommodate drilling a hole for the sensor.

The other plus for the microtensiometer is that, like the pressure bomb, the data is easy to interpret, with no calibrations, Blanco said. That’s what sets it apart from other plant-based sensors.

“For trunk dendrometers, you always need to have reference trees to calibrate against,” he said. Dendrometers measure the precise rate of growth in trunks or fruit, and the daily growth and shrinkage tracks tree water status to guide irrigation.

The research data show trunk dendrometers can also work well to guide irrigation programs. The WSU team ran their own calibrations, choosing reference trees to compare against, and did their own data interpretation. Most growers who use dendrometers, however, use the service package from Israel-based Phytech, which involves the tree sensors, soil and weather sensors, and the company’s analytics running in the background to deliver the water stress trends to growers via an app.

Phytech pairs the trunk dendrometers with fruit dendrometers, which the WSU team had more reservations about. They report higher variability and higher maintenance with this approach.

“If you choose just four apples to have an image of an entire orchard, that’s a huge constraint,” Blanco said. “It’s not a sensitive tool for water stress” the way the trunk dendrometer is, although he knows growers also use the sensors to hit fruit size targets.

The third sensor studied, sap flow sensors, offer continuous measurement of the water pulled from roots to leaves for transpiration, but Blanco said it’s a tricky tool to install properly and calibrate for canopy size. He sees it offering more value to scientists than commercial orchard use, at this point.

Grower Gilbert Plath, who hosted one of the apple trials in a Washington Fruit and Produce Co. Honeycrisp orchard, didn’t wait for the trial’s conclusions to start installing sensors.

“We’re using dendrometers at a lot of our ranches, mainly on Honeycrisp,” he said. “On Honeycrisp, we’re using deficit irrigation and riding the line on what it needs on water.”

While the microtensiometers may offer the highest level of precision — a priority for scientists — Phytech’s package of trunk and fruit dendrometers seems to be working to guide irrigation decisions, Plath said.

The WSU scientists make a good point that the dendrometers are at risk of being bumped out of position during orchard operations, Plath said, and that with only three fruit sensors, you risk basing decisions on a not-particularly representative sample. But his company takes steps to prevent those problems.

“We instituted an approach where every two weeks, we go through and check them, make sure they are on the right fruit,” Plath said. His team regularly tracks fruit counts and growth. “If something is not average, we’ll switch it off to something more average.”

—by Kate Prengaman

Leave A Comment