Fruit packing houses and storage facilities must regularly inspect and repair damaged areas such as walls and floors and aggressively clean and sanitize surfaces and equipment — above and beyond normal cleaning practices — to reduce the risk of Listeria contamination, according to a new study.

The study, initiated by Karen Killinger, formerly of Washington State University, and finished by project manager Ines Hanrahan of the Washington Tree Fruit Research Commission and Lauren Walter, a research intern at Washington State University, aimed to help fruit packing houses better track and manage Listeria in cold storage rooms.

Andre Harrell evenly coats floor drains with chlorine foam before scrubbing debris off surfaces during the workshop. (TJ Mullinax/Good Fruit Grower file photo)

To do so, they applied two levels of cleaning in two cold storage rooms in a central Washington warehouse.

Normal cleaning involved a full cleaning of all sections of the room, including coils, pans and cones, with untreated, pressurized water; scrubbing walls and ceiling with brushes and a pressure washer; and drying the floor with a squeegee vacuum.

Once most of the moisture was removed, the researchers used a chemical fogger for about two hours with fans on, cooling off and the doors closed to sanitize the room.

For aggressive cleaning, the researchers applied a chlorinated pressure wash (pH 6.5, 200 parts per million sodium hypochlorite) on all sections of the room, including coils, pans and cones; scrubbed walls and parts of ceiling with brushes and pressure washer; rinsed floors with chlorinated water and scrubbed with brushes; dried using a squeegee vacuum.

They took 373 total samples, both before and after cleaning, to compare the adequacy of each cleaning procedure.

The results showed several areas in the packing house that were more likely to harbor bacteria, including standing water on floors, in damaged areas on walls and floors, and the cooler condenser, which is difficult equipment to clean, Hanrahan said.

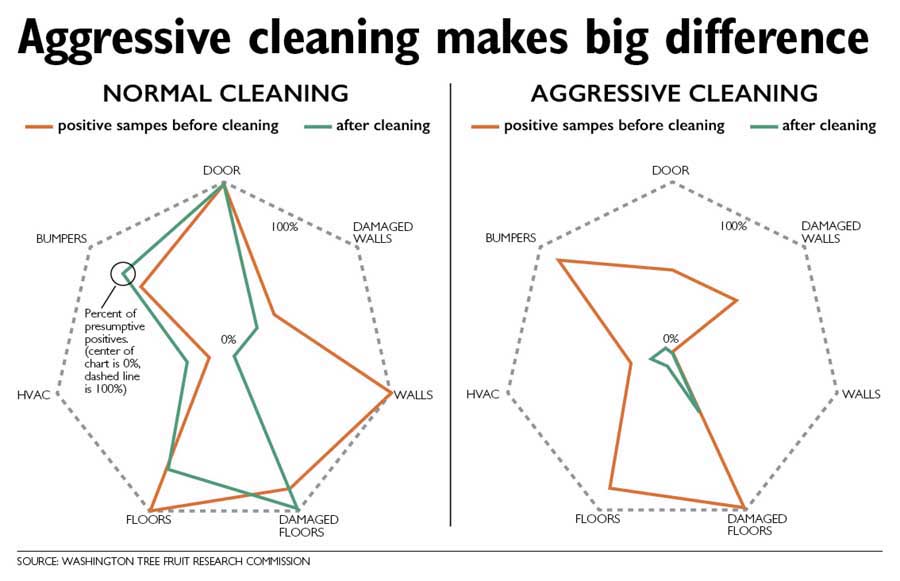

A study comparing normal and aggressive cleaning methods in cold storage rooms found the aggressive technique, which included a chlorinated pressure wash, resulted in a dramatic reduction in the number of positive generic Listeria samples. After normal cleaning, some of the areas — bumpers, HVAC systems and damaged floors — had a higher percentage of positive samples than before the cleaning. Source: Washington Tree Fruit Research Commission

Floors, in particular, required the more aggressive cleaning practices.

The researchers frequently observed generic Listeria after normal cleaning, but saw a dramatic reduction in the number of positive Listeria samples after aggressive cleaning practices were employed.

They also found that some areas of the cold storage room showed little change in Listeria after normal cleaning practices, including damaged floors, bumpers and HVAC systems; again, aggressive cleaning and sanitizing practices reduced the frequency of positive Listeria samples.

In addition, the floor scrubber used for the cleaning tested positive for Listeria and could serve as a source of contamination. “Attention to cleaning equipment is essential to limit cross contamination,” Hanrahan said. •

– by Shannon Dininny

Leave A Comment